Roller type curve design method in thin narrow material smoothing and rolling process

A technology of flat rolling and curve design, applied in computing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

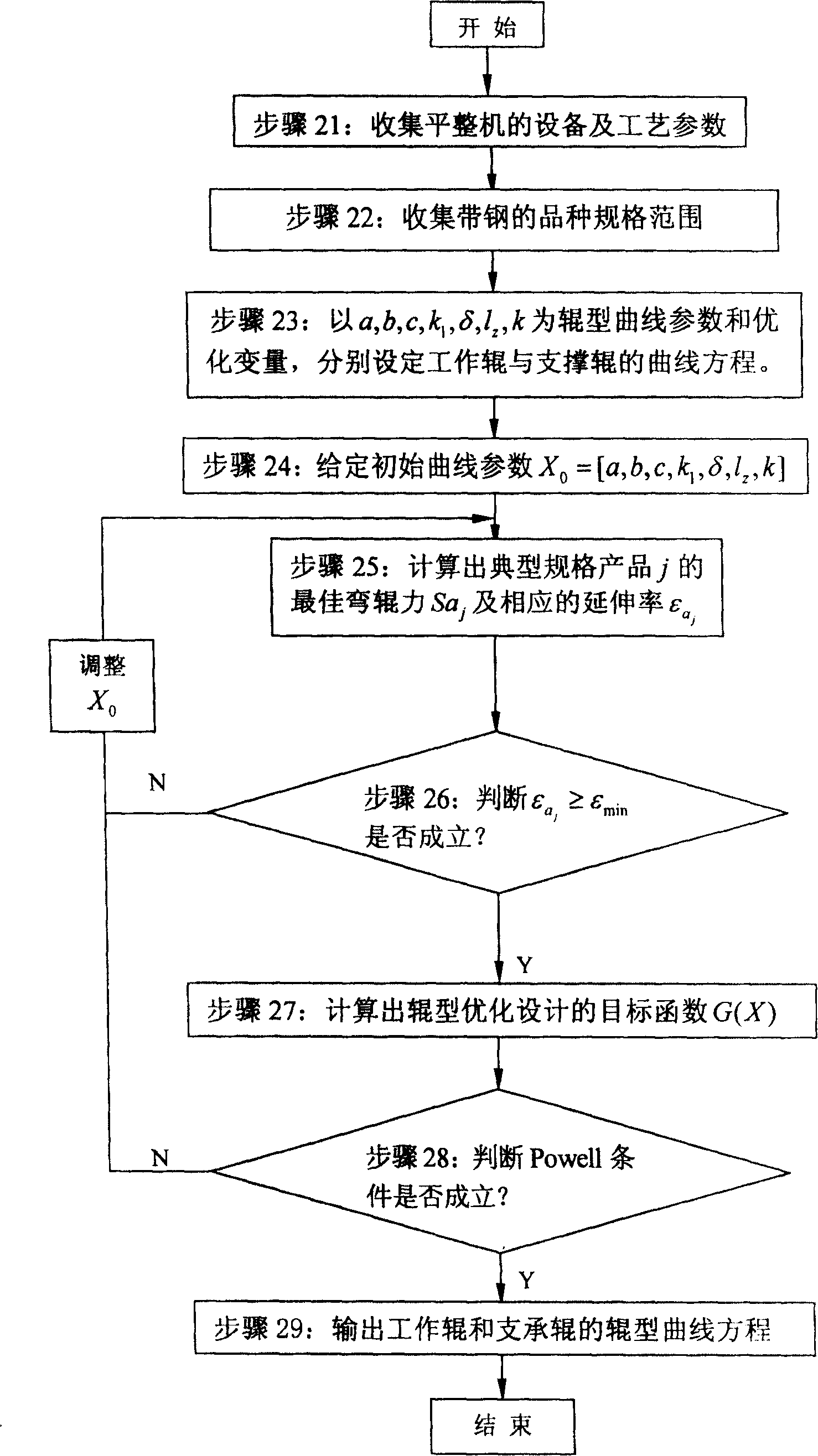

[0057] Provided below adopt the method optimization design of the present invention to design the work roll and back-up roll profile curve parameter solution process when certain common four-roller skin pass mill rolls thin and narrow material, as figure 2 shown.

[0058] First, in step 21, the equipment and process parameters of the skin pass mill are collected: work roll body length L w =1300mm, working roll diameter D w =φ440 / 480mm, back-up roll body length L b =1300mm, back-up roll diameter D b =φ1100 / 1200mm, the distance between the drive side of the backup roller and the center of the screw on the working side is l 1 = 2.32m, positive and negative bending rolls of working rolls, center distance between drive side and working side bending roll hydraulic cylinder l 2 =2.32m. The maximum bending force is ±60t, the maximum rolling pressure is 700t, and the maximum rolling speed is 1000m / min.

[0059] Subsequently, in step 22, the variety specification range of strip s...

Embodiment 2

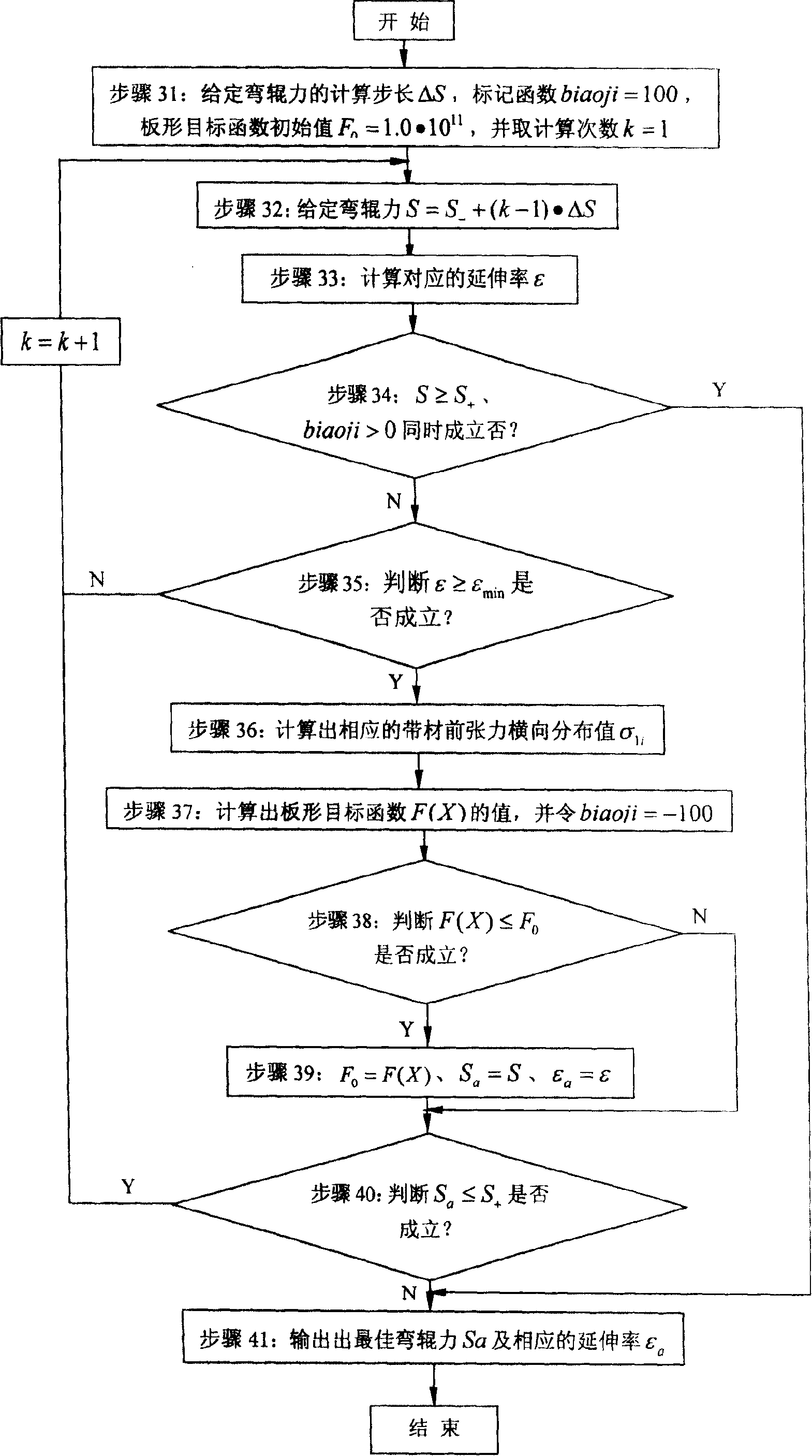

[0075] The calculation process of the optimal roll bending force when adopting the method of the present invention to solve a certain common four-roller skin pass mill rolling typical specification thin narrow material is given below, as image 3 shown.

[0076] The equipment and process parameters of the related tempering machine are: work roll body length L w =1300mm, working roll diameter D w =φ440 / 480mm, back-up roll body length L b =1300mm, back-up roll diameter D b =φ1100 / 1200mm, the distance between the drive side of the backup roller and the center of the screw on the working side is l 1 = 2.32m, positive and negative bending rolls of working rolls, center distance between drive side and working side bending roll hydraulic cylinder l 2 =2.32m. The maximum bending force is ±60t, the maximum rolling pressure is 700t, and the maximum rolling speed is 1000m / min.

[0077] Typical specifications of thin and narrow material width 800mm, thickness 0.15mm, yield strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com