Hydraulic self-sealed plunger oil-well pump

An oil pump and plunger technology, applied in the field of oil extraction machinery lifting, can solve problems such as increasing the cost of crude oil extraction, and achieve the effects of reducing energy consumption, increasing stroke length, and reducing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

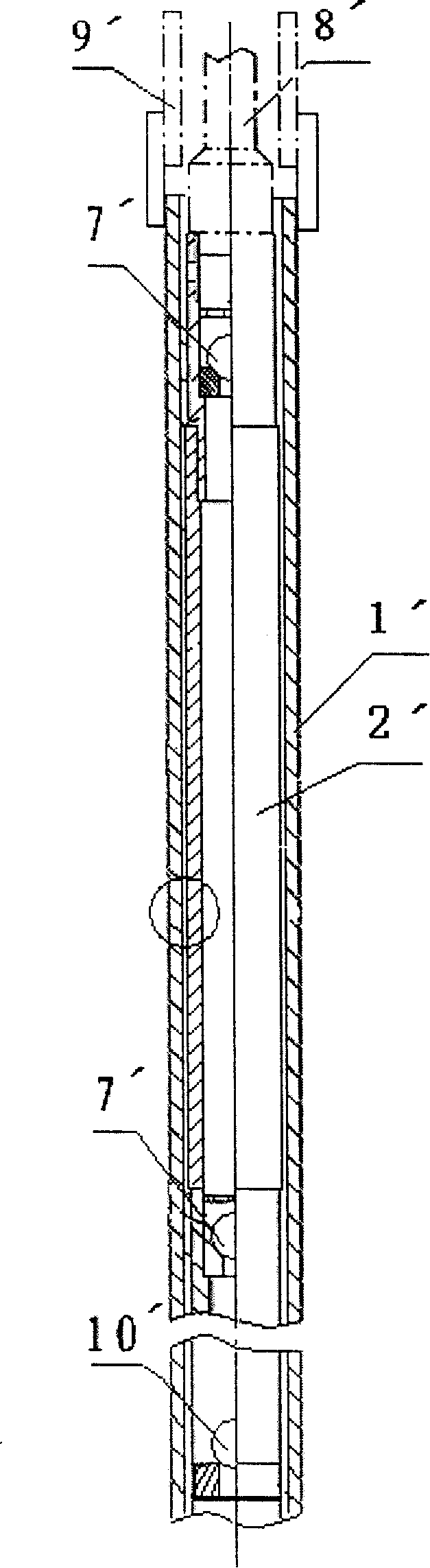

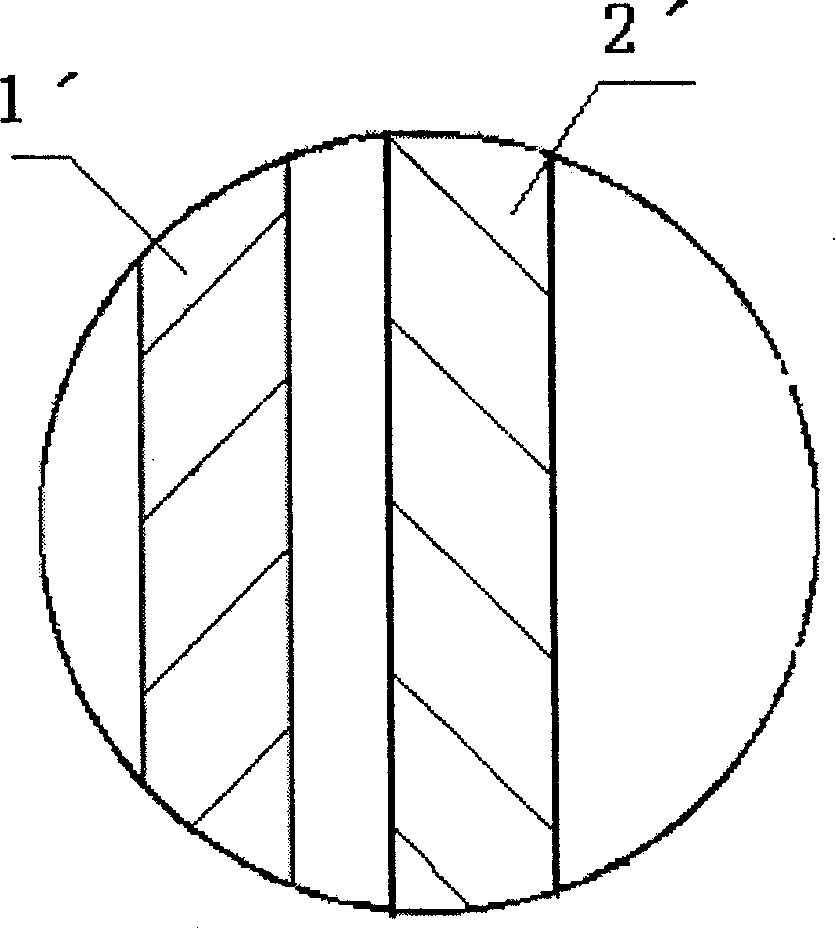

[0012] Conventional hydraulic plunger pump, see figure 2 and Figure 2A , including pump barrel 1', plunger 2', swimming valve 7', and fixed valve 10', wherein the swimming valve 7' is connected to the plunger 2' through a screw thread, and the plunger 2' is connected to the pump Cylinder 1' clearance fit; when in use, the pump cylinder 1' is connected with the oil pipe 9', the plunger 2' is connected with the sucker rod 8', and the sucker rod 8' drives the plunger 2' and the swimming valve 7' to be opposite Pump barrel 1' moves, swimming valve 7' opens on downstroke, lift fluid enters between fixed valve 10' in pump cylinder 1' and plunger 2', on upstroke, swimming valve 7' Closed, the oil is lifted to the surface through the plunger.

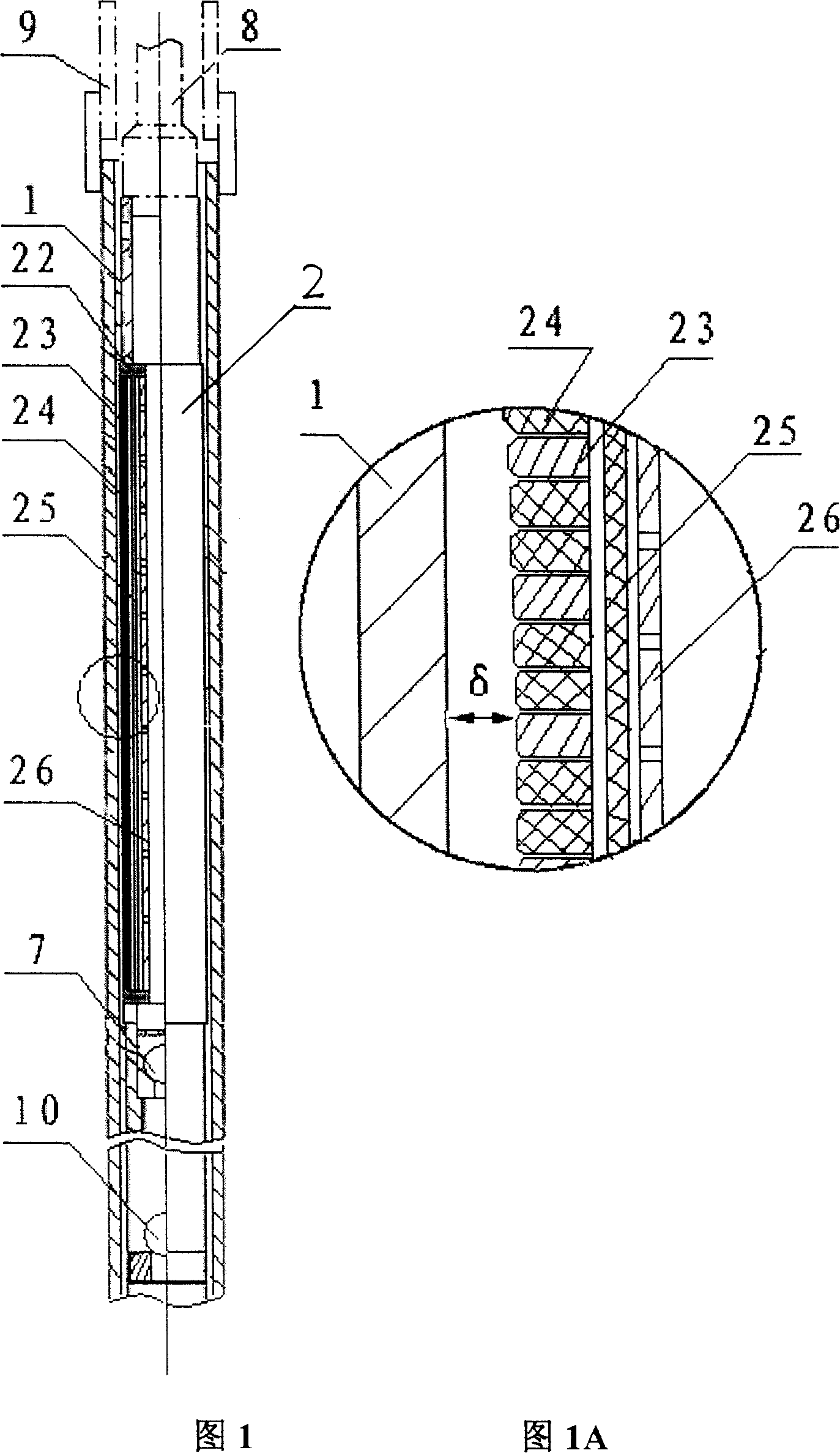

[0013] Referring to Fig. 1, the hydraulic self-sealing plunger oil well pump of the present invention also includes components such as a pump barrel 1, a plunger 2, a movable valve 7 and a fixed valve 10, and the movable valve 7 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com