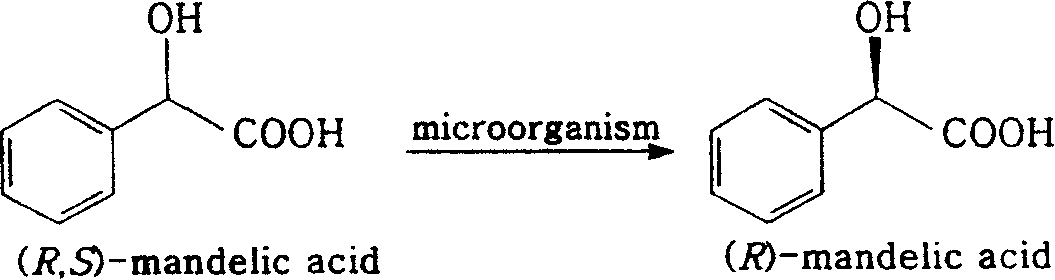

Process for preparing (R)-mandelic acid by microbial asymmetric resolution

An asymmetric, mandelic acid technology, applied in the field of biological resolution of racemic compounds, can solve the problems of many by-products, difficult separation of products and substrates, and difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Cultivation of bacterial strains: The composition of the medium is that the components contained in each 100ml of culture solution are in grams: glucose 0.25-1.0, meat extract 0.5-2.0, peptone 0.5-2.0, yeast extract 0.1-0.5, (NH 4 ) 2 HPO 4 0.5~1.0, KH 2 PO 4 0.25~0.5, MgSO 4 ·7H 2 O 0.025~0.1, NaCl 0.001~0.005, ZnSO 4 ·7H 2 O0.001~0.005, FeSO 4 ·7H 2 O 0.001~0.005, CuSO 4 ·5H 2 O 0.0001~0.0005, MnSO 4 4H 2 O 0.0001~0.0005.

[0062] The culture conditions are as follows: the initial pH is 6.0-8.0, the filling volume is 20%, the culture temperature is 30° C., the rotation speed of the shaking flask is 100-300 rpm, and the culture time is 48 hours.

Embodiment 2

[0064] Preparation of whole cells: B.flavum AS 1.818 was inoculated in a 250ml shake flask with a liquid volume of 20%, and cultured at 30°C and 100-300rpm for 48 hours with shaking; after the cultivation, the cells in the fermentation broth were centrifuged and washed with normal saline Twice, the collected cells were stored in a 4°C refrigerator for splitting reactions.

Embodiment 3

[0066] Preparation of (R)-mandelic acid by asymmetric resolution by microbial method: in 2 mL of potassium phosphate buffer containing 10 mg of racemic mandelic acid at 0.2 mol / L, pH 7.0, add 0.1 g (i.e. weight to volume ratio 5%) B. flavumAS 1.818 bacterial cells, 25°C, 150 rpm, transformed for 72 hours, centrifuged the transformed solution, collected the supernatant, adjusted the pH to 1.0 with 3mol / L hydrochloric acid, extracted with 2.5 times the volume of ethyl acetate, and separated The ethyl acetate layer was dehydrated with anhydrous sodium sulfate, dried in vacuum at low temperature, and the residual solid was dissolved with a mixed solution of n-hexane and isopropanol (volume ratio of 9:1), and the product (R)-mandelic acid had an optical purity of 90.83 %e.e, yield 38.63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com