LED module with high-efficient radiation

A light-emitting diode, high-efficiency technology, applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of related circuits not working properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

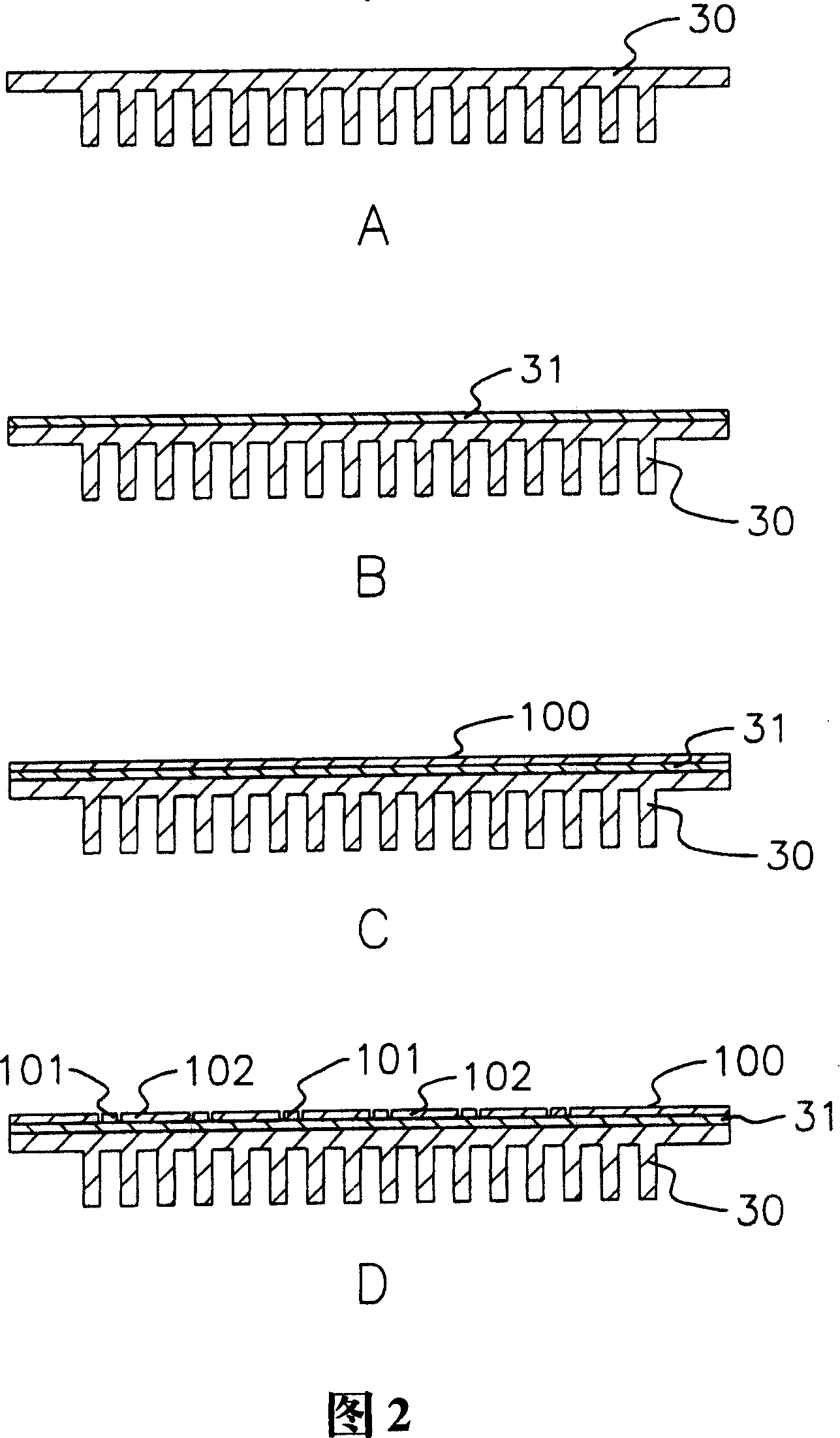

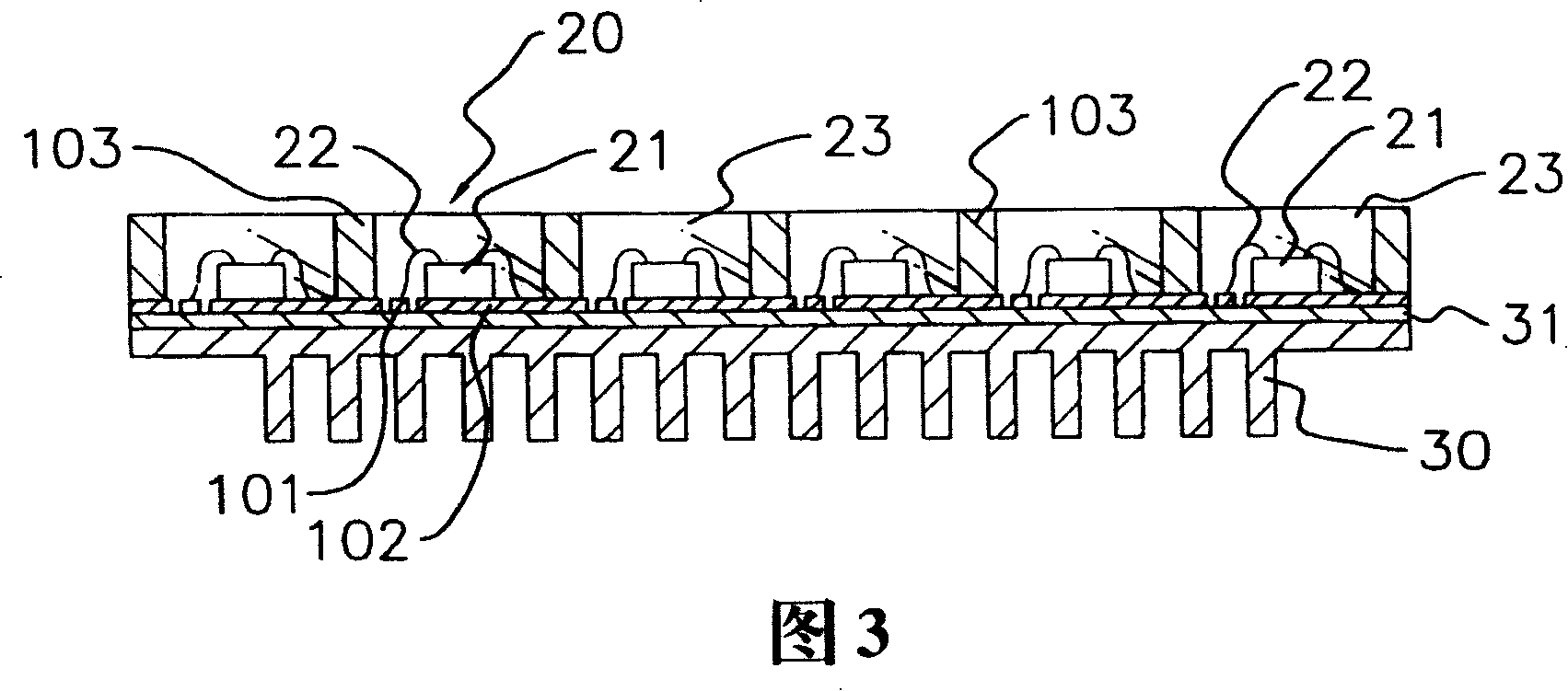

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0029] A preferred embodiment of the present invention is shown in FIG. 1, the efficient heat dissipation LED module 10 includes:

[0030] A circuit layer 100, forming a specific circuit layout on the high thermal conductivity material;

[0031] A plurality of light-emitting diodes 20 are formed on the aforementioned circuit layer after the steps of chip loading, wire bonding, and glue sealing, and are connected to each other through the circuit of the circuit layer 100;

[0032] A heat sink 30 is in direct contact with the insulating oxide layer at the bottom of the circuit layer 100 , or bonded to the bottom surface of the circuit layer 100 through a thermally conductive adhesive 31 to provide a larger heat dissipation area.

[0033] Can find out the basic composition of a preferred embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com