Active driving organic electroluminescent display structure

An organic light-emitting layer and luminescent technology, applied in the direction of electroluminescent light source, electric light source, static indicator, etc., can solve problems such as unstable luminous brightness and decreased OLED brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

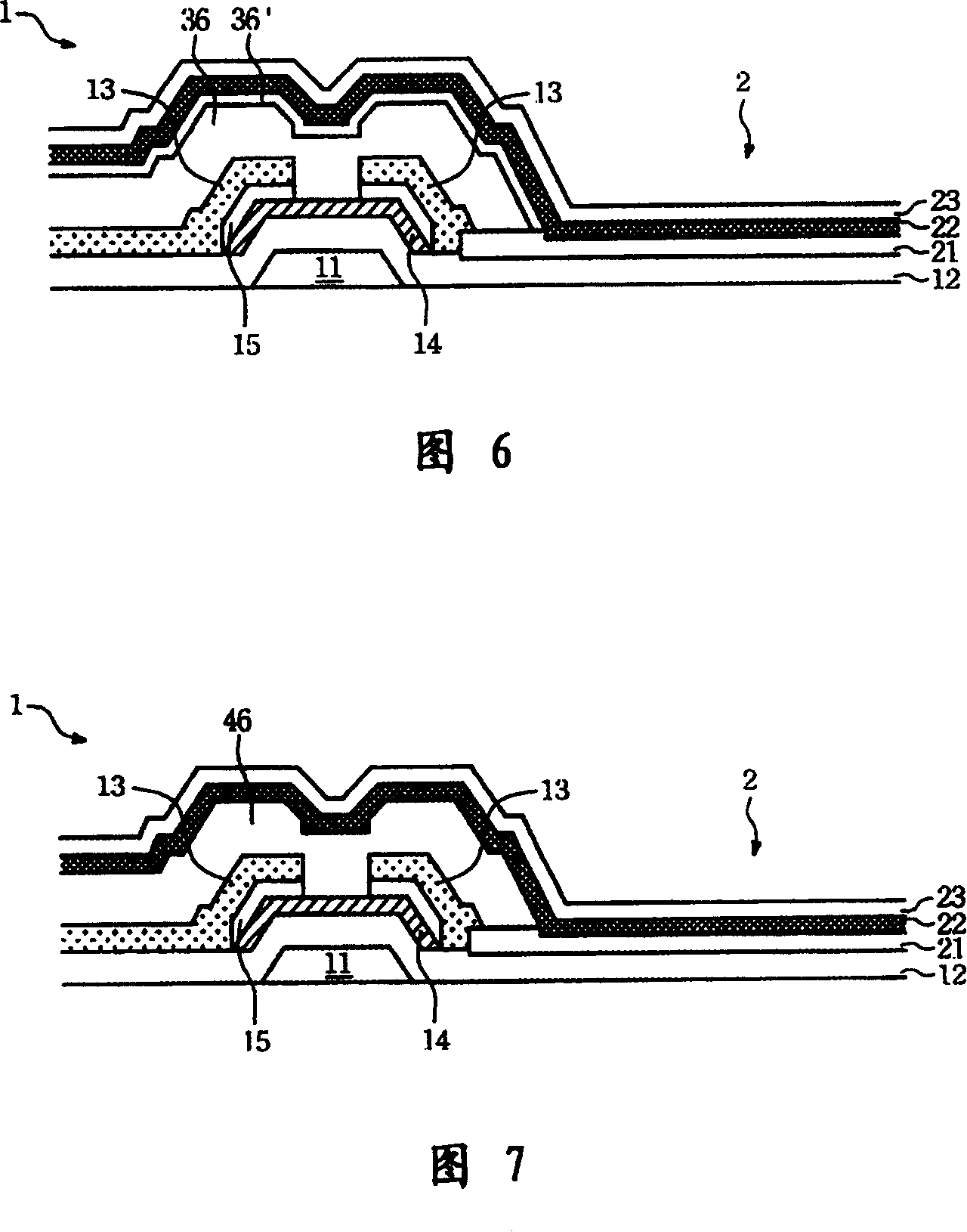

[0039] Fig. 5 shows a first embodiment of the structure of the protective layer of the TFT of the present invention. A multi-layer protective layer 26 is fabricated to increase the anti-leakage current capability of the protective layer 26 . For example, SiNx with a thickness of 3000 angstroms can be plated in multiple layers (more than two layers), or SiNx can be plated with other dielectric materials alternately. In FIG. 5 , the protection layer 26 is composed of two layers 261 , 262 . By increasing the thickness of the dielectric layer of the protection layer and increasing the interface of the dielectric film due to multi-layer plating, the anti-leakage current capability of the protection layer 26 can be double enhanced.

[0040] In addition, the present invention provides another preferred embodiment, performing thermal oxidation treatment on the surface of the protection layer to increase the anti-leakage current capability of the protection layer. Fig. 6 shows the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com