Method for manufacturing high strength and highly wear-resisting flashboard

A manufacturing method and high wear-resistant technology, applied in the field of gate material selection and preparation technology, can solve the problems of easy cracking, gate cracking, gate failure, etc., and achieve increased strength and wear resistance, simple preparation process, Simple and advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

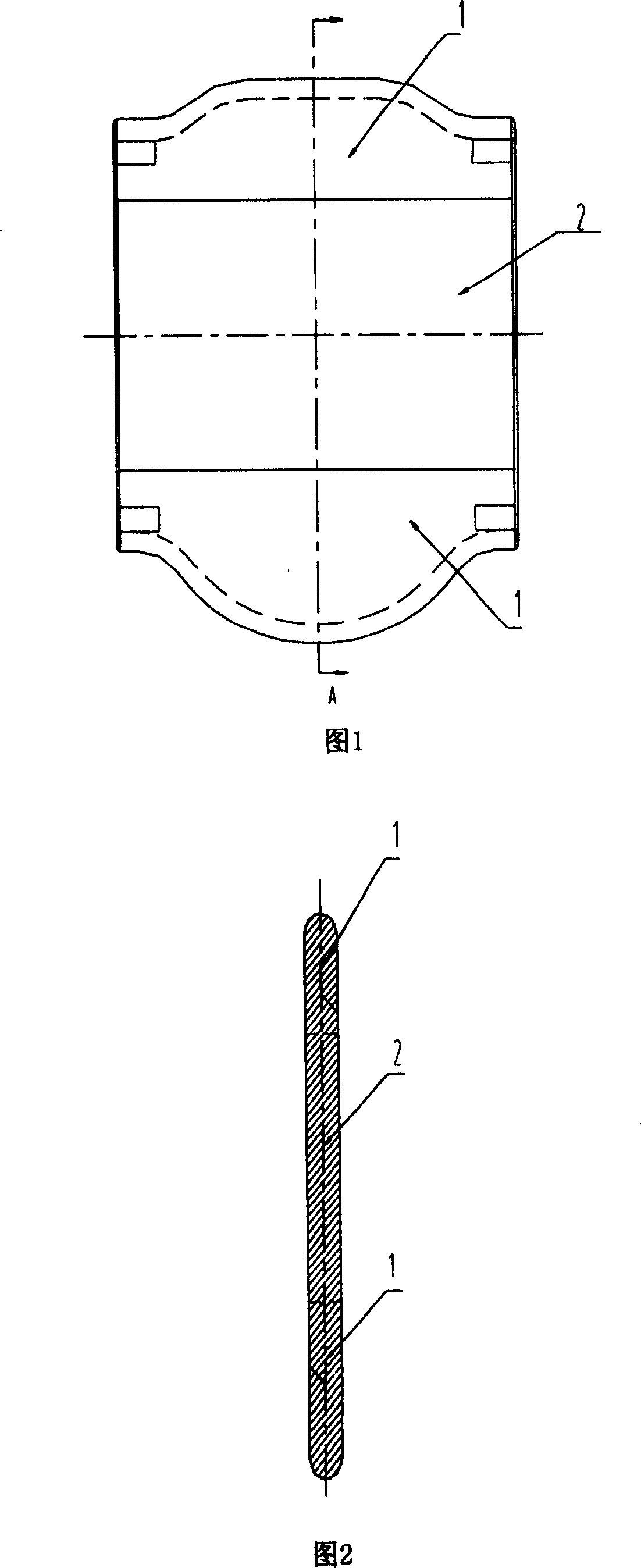

[0017] Embodiment 1: A preparation process of a gate plate, using 16Mn alloy steel as the base material of the gate plate, the strength, wear resistance and corrosion resistance of this material are all better than ordinary carbon steel. First process the 16Mn alloy steel into a gate according to the requirements of the drawings, and then heat the processed gate at 200°C for 1 hour for complete annealing. After grinding and cleaning the first and second working surfaces 1 and 2 (as shown in Figures 1 and 2) of the gate plate, ion implantation of tungsten carbide is performed on the first working surface 1. The specific steps are: 1), ion Infiltrating tungsten: the vacuum degree of the treatment furnace is 5-10Pa, and the pulse current beam density is 2-2.5mA / cm 2 , the pulse frequency is 30HZ, the accelerating voltage is between 20KV, the implantation energy of tungsten ions is at 100KeV, the concentration of implanted tungsten ions is 25-30%, and the time of infiltrating tung...

Embodiment 2

[0018] Example 2: First, the 38CrMoAlA alloy steel is machined into a ram according to the drawings, and then the ram is fully annealed at 220° C. for 1.5 hours. After grinding and cleaning the first and second working surfaces 1 and 2 (as shown in Figures 1 and 2) of the ram, perform ion implantation tungsten carbide treatment on the first working surface 1, the specific steps are 1) ion implantation and infiltration Tungsten: The vacuum degree of the treatment furnace is 0.5~2Pa, and the pulse current beam density is 2~5mA / cm 2 , the pulse frequency is 70HZ, the accelerating voltage is 30KV, the implantation energy of tungsten ions is 200KeV, the concentration of implanted tungsten ions is 30-40%, and the time of infiltrating tungsten ions is 30h. After processing, the ram is slowly cooled with the furnace in the furnace, and then the ram is taken out. 2) Carburizing and quenching treatment: Put the ram that has completed step 1) into an ordinary carburizing furnace, heat i...

Embodiment 3

[0019] Example 3: Firstly, the 16Mn alloy steel is machined into a ram according to the drawing, and then the ram is fully annealed at 250° C. for 2 hours. After grinding and cleaning the first and second working surfaces 1 and 2 (as shown in Figures 1 and 2) of the ram, perform ion implantation tungsten carbide treatment on the first working surface 1, the specific steps are 1) ion implantation and infiltration Tungsten: The vacuum degree of the treatment furnace is 20-30Pa, and the pulse current beam density is 0.5-2mA / cm 2 , the pulse frequency is 80-100HZ, the accelerating voltage is 40KV, the implantation energy of tungsten ions is 300KeV, the concentration of implanted tungsten ions is 40-50%, and the time of infiltrating tungsten ions is 36h. The gate plate is taken out after the gate plate is slowly cooled with the furnace in the furnace. 2) Carburizing and quenching treatment: put the ram that has completed step 1) into an ordinary carburizing furnace, slowly heat it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com