Modification method for cathode activated charcoal of ultracapacitor

A technology for supercapacitors and modification methods, which is applied in the fields of capacitors, capacitor manufacturing, hybrid/electric double layer capacitor manufacturing, etc., and can solve the problems of low capacity and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

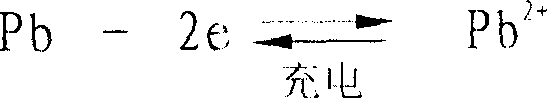

Image

Examples

Embodiment 1

[0010] Embodiment 1: Barium sulfate is as the active center of lead phosphate

[0011] At room temperature, the pretreated activated carbon was mixed with 1 mol / l Pb(NO 3 ) 2 Vacuum soak in the solution for 3 hours, dry at 100°C for 2 hours after suction filtration, then add excess 0.05mol / l phosphoric acid solution and vacuum soak for 5 hours. 3 (PO 4 ) 2 The modified layer was washed with water and filtered until the pH was greater than 6.5, and dried at 100° C. for 6 hours to complete the lead phosphate modification.

[0012] The activated carbon modified by lead phosphate was mixed with 0.03mol / l Ba(NO 3 ) 2 Vacuum impregnation in the solution at room temperature for 3 hours, suction filtration, drying at 100°C for 2 hours, and then adding an excess of 0.05 mol / l K 2 SO 4 The solution was vacuum impregnated for 5 hours, at which time a layer of nanoscale BaSO was deposited in the micropores of the activated carbon. 4 The modified layer was washed with water and suc...

Embodiment 2

[0013] Embodiment 2: barium sulfate is as the active center of lead sulfate

[0014] At room temperature, the pretreated activated carbon was mixed with 1 mol / l Pb(NO 3 ) 2 Vacuum impregnated in the solution for 3 hours, dried at 100°C for 2 hours after suction filtration, and then added excess density of 1.3g / cm 3 The sulfuric acid solution was vacuum impregnated for 5 hours, at which time a layer of nanoscale PbSO was deposited in the micropores of the activated carbon 4 The modified layer was washed with water and filtered until the pH was greater than 6.5, and dried at 100° C. for 6 hours to complete the lead sulfate modification.

[0015] The activated carbon modified by lead sulfate was mixed with 0.03mol / l Ba(NO 3 ) 2 Vacuum impregnate in the solution for 3 hours at room temperature, dry at 100°C for 2 hours after suction filtration, and then add an excess of 0.05mol / l K 2 SO 4 The solution was vacuum impregnated for 5 hours, at which time a layer of nanoscale BaS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com