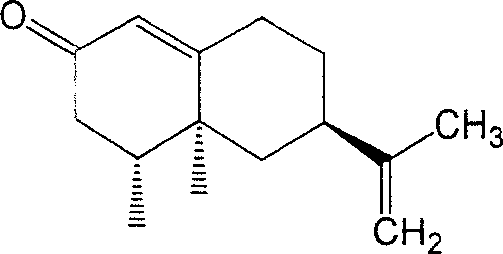

Method for synthesizing nootkatone, and its application

A synthetic method, the technology of noka ketone, applied in the field of synthesis of unsaturated ketene compounds, can solve the problems of limited dosage, difficulty in isolation, low content, etc., and achieve the effects of good selectivity, convenient post-treatment, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Take an appropriate amount of commercially available valerian oil and mix it evenly with a suitable porcelain filler and put it into the extraction kettle. According to the experimental conditions, the extraction kettle, the separation kettle and the cooling water bath are heated or cooled respectively to reach the set value. temperature (60°C). Turn on the CO 2 Add a certain amount of entrainer (alcohol or propylene glycol) to the gas cylinder and the entrainer pump, and pressurize the system through the high-pressure pump. After reaching the conditions, soak statically for 30 minutes, then perform dynamic extraction for 15 minutes, CO 2 The flow rate is 2-5L / min. Samples were taken every 2 hours to obtain the balenylenene product with a total yield of 1.2%. The extraction experimental conditions are listed in the table below.

[0015] temperature(℃)

Pressure (MPa)

Entrained dose (%)

60

30

10

[0016] (2) Mix ...

Embodiment 2

[0020] (1) Take an appropriate amount of commercially available valerian oil and mix it evenly with a suitable porcelain filler and put it into the extraction kettle. According to the experimental conditions, the extraction kettle, the separation kettle and the cooling water bath are heated or cooled respectively to reach the set value. temperature (50°C). Turn on the CO 2 Add a certain amount of entrainer (alcohol or propylene glycol) to the gas cylinder and the entrainer pump, and pressurize the system through the high-pressure pump. After reaching the conditions, soak statically for 20 minutes, then perform dynamic extraction for 10 minutes, CO 2 The flow rate is 2-5L / min. Samples were taken every 2 hours to obtain the balenylenene product with a total yield of 1.0%. The extraction experimental conditions are listed in the table below.

[0021] temperature(℃)

Pressure (MPa)

Entrained dose (%)

50

25

10

[0022] (2) Mix ...

Embodiment 3

[0026] (1) Take an appropriate amount of commercially available valerian oil and mix it evenly with a suitable porcelain filler and put it into the extraction kettle. According to the experimental conditions, the extraction kettle, the separation kettle and the cooling water bath are heated or cooled respectively to reach the set value. temperature (70°C). Turn on the CO 2 Add a certain amount of entrainer (alcohol or propylene glycol) to the gas cylinder and the entrainer pump, and pressurize the system through the high-pressure pump. After reaching the conditions, soak statically for 40min, then perform dynamic extraction for 25min, CO 2 The flow rate is 2-5L / min. Samples were taken every 2 hours to obtain the balenylenene product with a total yield of 1.1%. The extraction experimental conditions are listed in the table below.

[0027] temperature(℃)

Pressure (MPa)

Entrained dose (%)

70

35

10

[0028] (2) Mix 20g of bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com