New process for separating metal fiber copper protective layer by catalytic ammonia leaching method

A technology for copper protective layer and metal separation, which is applied in the field of separation of metal fiber copper protective layer by catalytic ammonia immersion method, can solve the problems of long electrolysis process, difficult acid mist treatment, and metal fiber quality degradation, and achieve high added value of recovery and easy Effect of recycling and improving reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by way of examples.

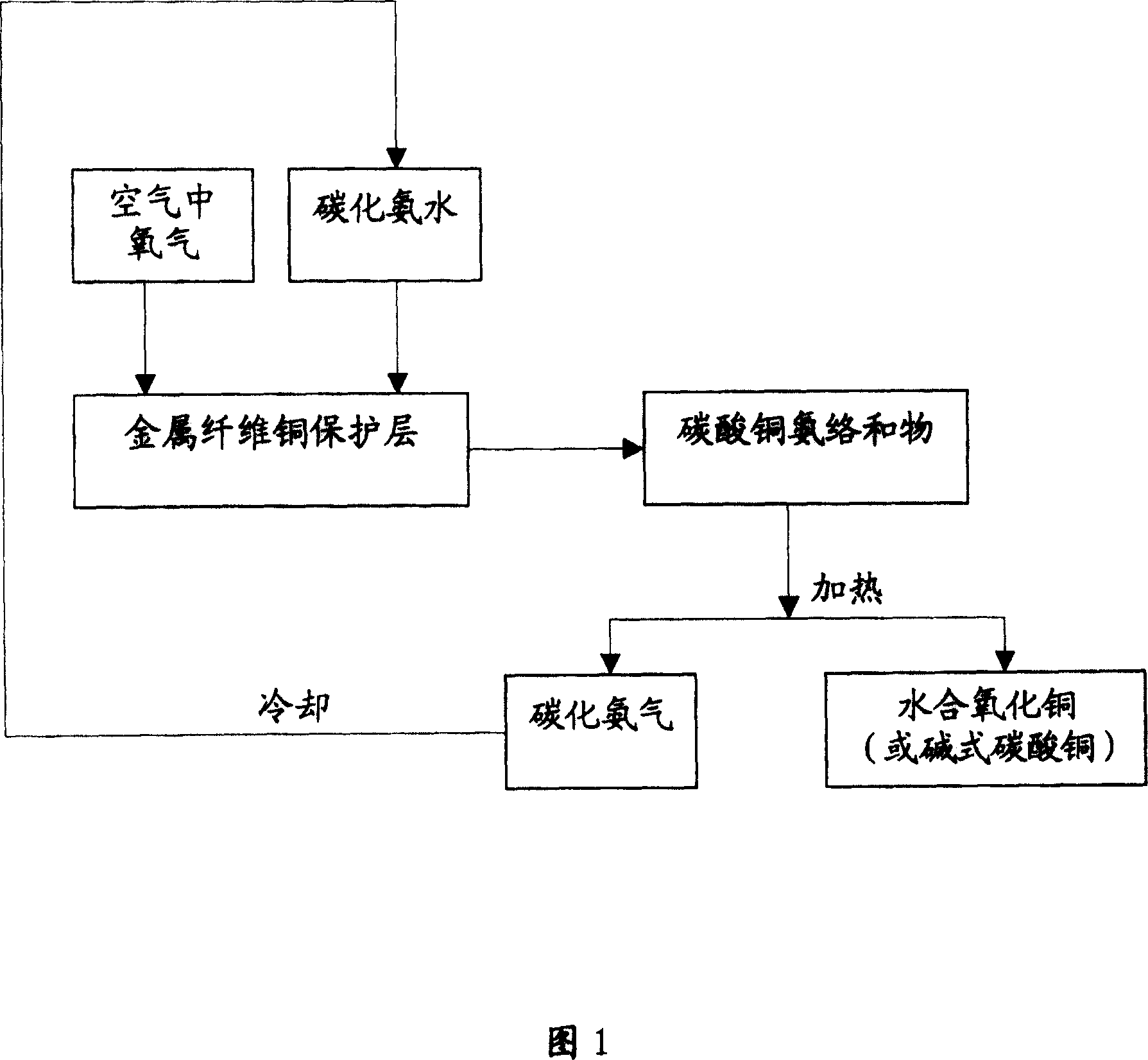

[0011] As shown in Figure 1, the embodiment that implements the new process of separation metal fiber copper protective layer of catalytic ammonia leaching method of the present invention is as follows:

[0012] Use the principle of high-speed water jetting in the system to inhale oxygen in the air, so that the fluid is atomized at the nozzle by high-speed and high-pressure effects, so that the oxygen in the inhaled air can be dissolved at a high speed, and then evenly pass through the screen, and the metal fiber protective layer copper Electrochemical reaction occurs to oxidize it, and then add carbonized ammonia water to make the metal fiber copper protective layer complex in the carbonized ammonia water medium at a high speed to form copper carbonate ammonium complex, and then use its own circulation system to send the solution into the thermal decomposition tank for heating , by he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com