Composite material for interior decoration of automobiles and manufacturing method thereof

A technology for automotive interiors and composite materials, applied in the field of composite materials for automotive interiors and its manufacturing, can solve the problems of being unsuitable for the production of small batches and multi-variety products, reducing the efficiency of extruders, and inconsistent production rhythms. The effect of reducing equipment investment cost, light weight, and total cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

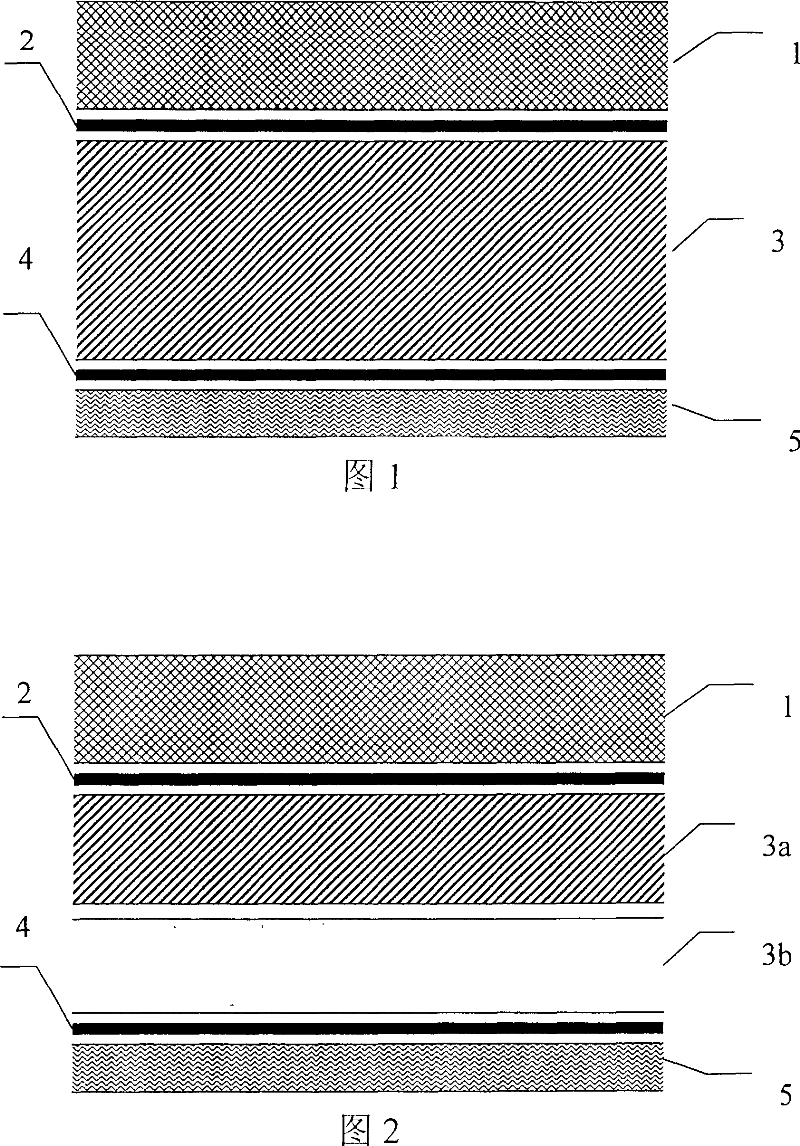

[0045] (A) The specific composition of the automotive interior composite material shown in Figure 1 is as follows:

[0046] The first layer of fabric (1) is a polyester fiber non-woven blanket of 600 g / m2

[0047] The second release layer (2) is a polyester fiber non-woven fabric of 120 g / m2

[0048] The third sandwich layer (3) is composed of a sheet of 2400 g / m2 hot melt felt, in which the weight percentage of polypropylene fiber and recycled cotton fiber is 50%:50%

[0049] The fourth release layer (4) is 120 g / m2 polyester fiber non-woven fabric

[0050] The fifth bottom material layer (5) is 400 g / m2 polypropylene fiber non-woven blanket

[0051] (B) The specific steps of the above-mentioned composite material manufacturing are as follows:

[0052] (1) Lay the sheets to be heated in layers from bottom to top: the release layer (4) is placed on the lower layer, and the sandwich layer (3) is selected from hot melt felt, placed on the second layer, and the upper layer is the rel...

Embodiment 2

[0056] (A) The specific composition of the composite material in the interior of the automobile as shown in Figure 2 is as follows:

[0057] The first fabric layer (1) is a polyester fiber non-woven blanket of 600 g / m2

[0058] The second release layer (2) is a polyester fiber non-woven fabric of 120 g / m2

[0059] The third sandwich layer (3) is composed of two kinds of sheets: 2000 g / m2 hot-melt felt (3a) and 400 g / m2 polypropylene felt (3b), among which the polypropylene fiber in the hot-melt felt and recycled The weight percentage of cotton fiber is 40%:60%, and (3a) is placed on (3b).

[0060] The fifth release layer (4) is 120 g / m2 polyester fiber non-woven fabric

[0061] The sixth bottom material layer (5) is 400 g / m2 polypropylene fiber non-woven blanket

[0062] (B) The specific steps of the above-mentioned composite material manufacturing are as follows:

[0063] (1) Lay the sheets to be heated in layers from bottom to top, the release layer (4) is placed on the lower la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com