Groove inside reflection type jewel machining process

A processing and reflective technology, which is applied in the field of reflective cut gemstone processing technology in grooves, can solve the problems of not being able to fully play the role of optical properties, and achieve the effect of improving internal quality and optical effects and saving processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

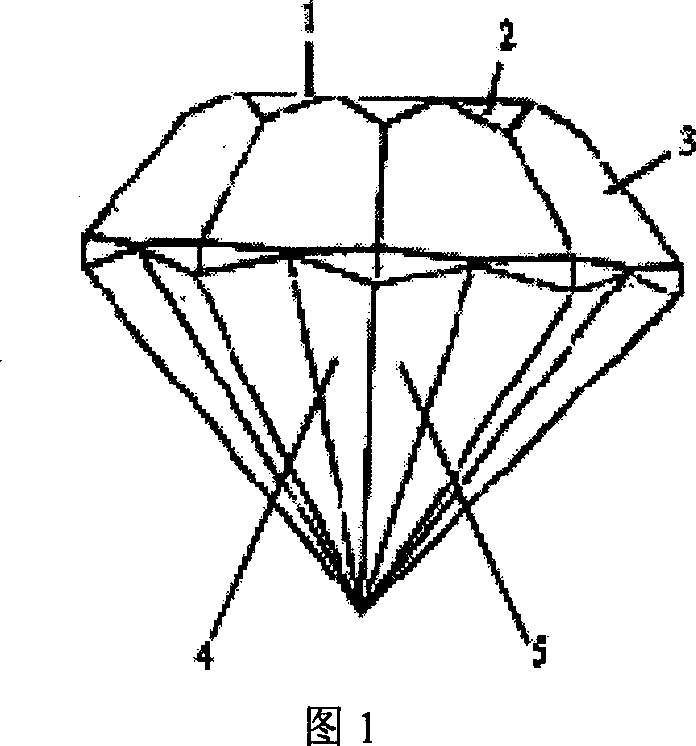

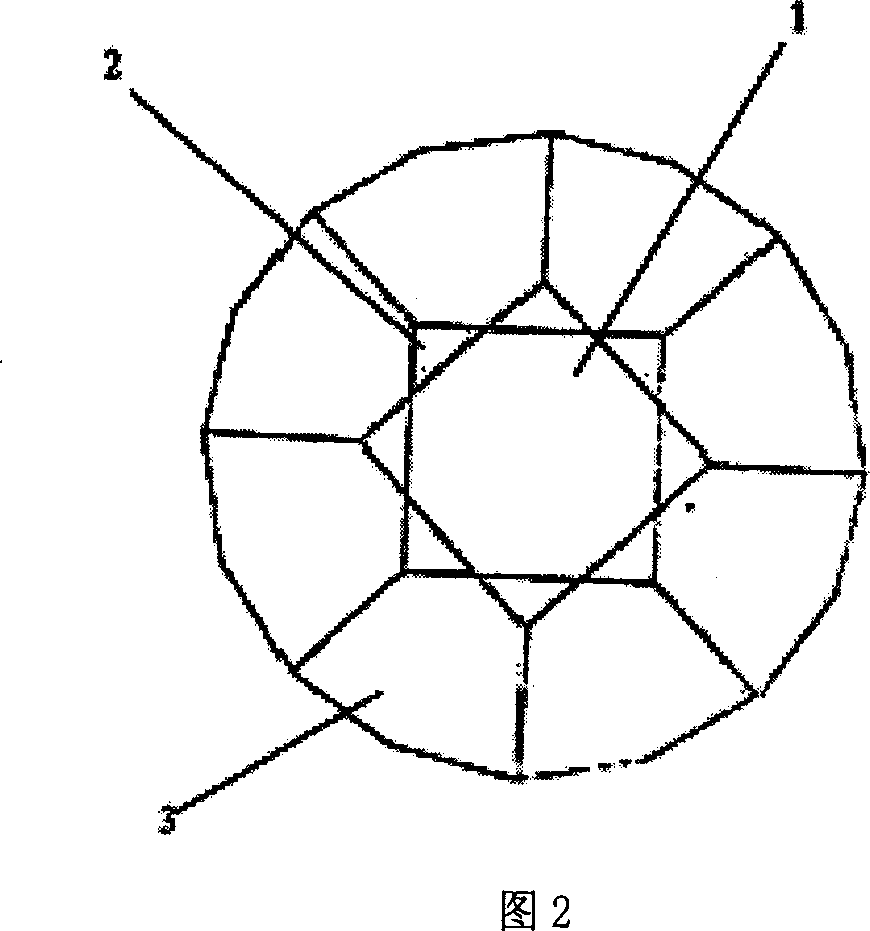

[0019] a. Use an ordinary gemstone grinding and polishing machine to preform the crystal and the table top (1) to grind and polish the thickness, and then use the traditional processing method to grind the 8 main facets (3) and 8 star facets (2) on the crown of the gemstone. After the grinding is complete, the main facet (3) angle of the crown is ground out according to the conventional angle of the gemstone variety, and all the facets are polished to complete the processing of the crown;

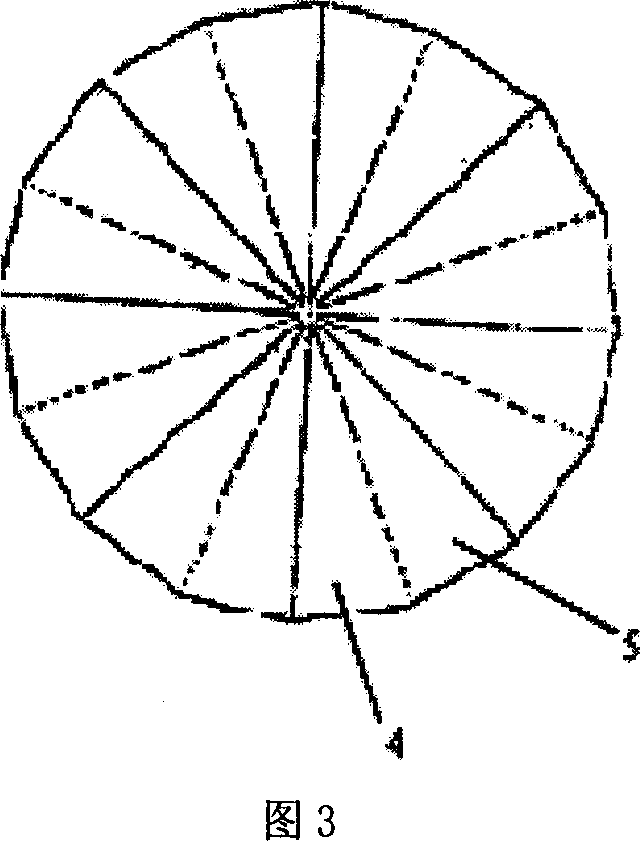

[0020] b. The pavilion of the gemstone is also ground at a conventional angle to produce 4 pavilion left main facets (4) and 4 pavilion right main facets [5]. The pavilion must be pointed, and all facets do not need to be polished;

[0021] c. Put the polished gemstones in the wooden seat that can fix the gemstones, and then use a hanging drill with a flexible shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com