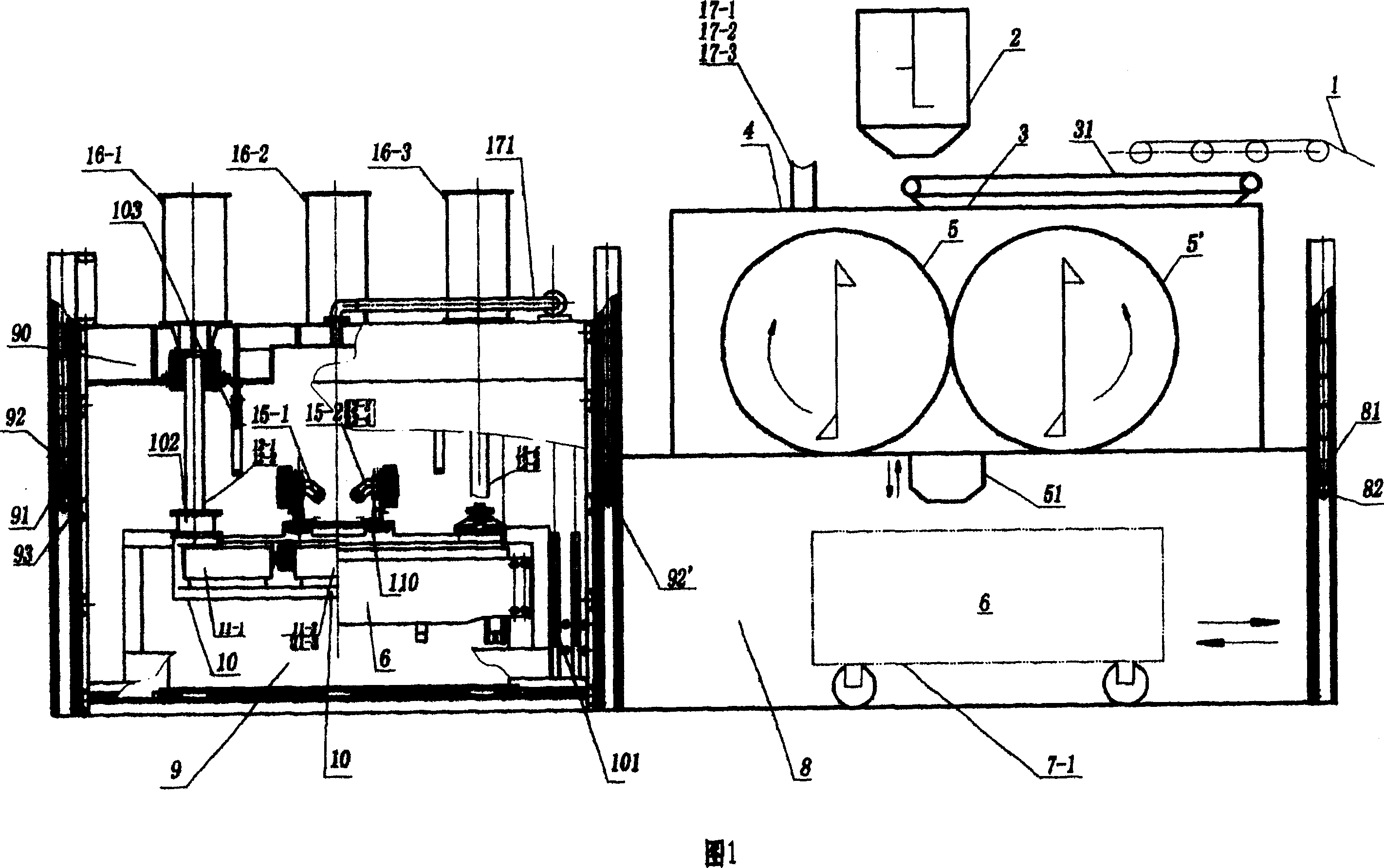

Process and device for producting artificial stone

A production process, artificial stone technology, applied in the direction of control devices, manufacturing tools, ceramic molding machines, etc., can solve the problems of undesigned product structure and compactness, and achieve beautiful and durable products, fully and evenly bonded, and smooth appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

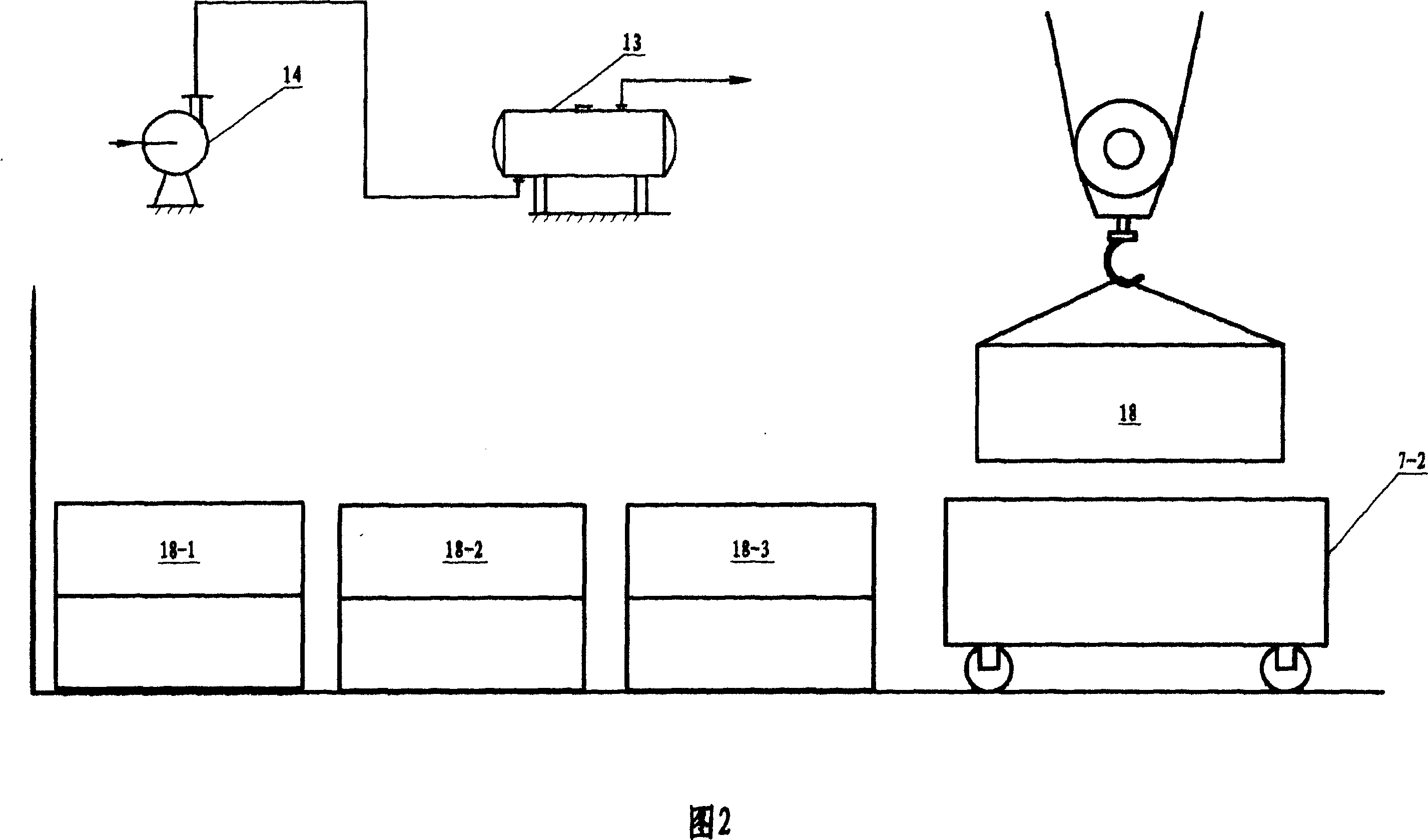

Method used

Image

Examples

example 1

[0035] Example 1: Artificial pebbles

[0036] Gravel 4200Kg

[0037] Stone powder 3600Kg, including 20 mesh, 40 mesh, 60 mesh, 80 mesh, 100 mesh, 325 mesh, 800 mesh

[0038] Unsaturated polyester 400Kg

[0039] Initiator 5.5Kg

[0040] 20Kg of titanium dioxide makes blocks weighing about 8200Kg

example 2

[0041] Example 2: Artificial white stone

[0042] Gravel 4000Kg, white, ranging in size from 2cm to 12cm;

[0043] Stone powder 3800Kg

[0044] Unsaturated polyester 400Kg

[0045] Initiator 5Kg

[0046] Titanium dioxide 10Kg

example 3

[0047] Example 3: Artificial marble

[0048] Gravel 6500Kg, ranging in size from 1.8cm to 12cm;

[0049] Stone powder 325 mesh 600Kg 0~0.6 mesh 250Kg 0.6~1.8 mesh 450Kg

[0050] Unsaturated polyester 340Kg, initiator 5Kg, titanium dioxide 20Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com