Process of preparing monodisperse nanometer semiconductor selenide particle

A nanoparticle, monodisperse technology, applied in selenium/tellurium compounds, chemical instruments and methods, binary selenium/tellurium compounds, etc., can solve the problems of difficult product size and control, achieve low cost, wide applicability, overcome the Effects of cost and environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example 1,

[0019] Weigh 0.7g of NaOH into a mixed solvent of 10ml of oleic acid and 15ml of ethylene glycol. After fully reacting for about 30 minutes, weigh 0.8g of analytically pure silver nitrate and dissolve it in 20ml of water. Weigh 0.4g of analytically pure selenium powder and prepare it into The silver ion solution and selenium powder are added to the mixed solvent, stirred evenly, placed in a 40ml stainless steel pressure-resistant reactor, reacted at 140°C for 24 hours, the resulting precipitate is centrifuged, washed, and dried to obtain black powder. The product was identified as silver selenide by X-ray powder diffraction; its morphology was analyzed with a transmission electron microscope (TEM), and it was observed that its morphology was monodisperse nanoparticles with a particle size of about 20nm.

Example Embodiment

[0020] Example 2:

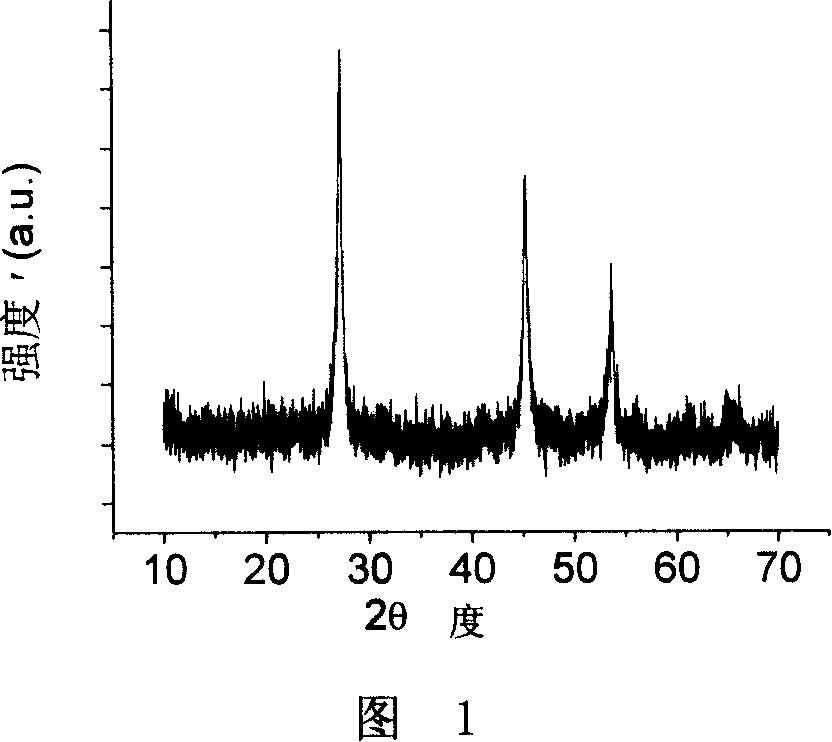

[0021] Weigh 0.5g NaOH into a mixed solvent of 5ml oleic acid and 10ml ethanol. After fully reacting for about 30mins, weigh 1g analytically pure zinc chloride and dissolve it in 20mL water, weigh 0.8g analytically pure selenium powder, and prepare it. The zinc ion solution and selenium powder were added to the mixed solvent, stirred evenly, placed in a 40ml stainless steel pressure-resistant reactor, and reacted at 180°C for 24h. The resulting precipitate was separated by centrifugation, 1mol·L -1 After washing with NaOH solution, washing with deionized water, and drying, a yellow powder is obtained. The product as shown in Figure 1 was identified as zinc selenide by X-ray powder diffraction; the morphology of the product was analyzed by a transmission electron microscope (TEM), and it can be seen from Figure 2 that its morphology was monodisperse nanoparticles with a particle size in Between 15-20nm.

Example Embodiment

[0022] Example 3:

[0023] Weigh 0.4g KOH into a mixed solvent of 10ml oleic acid and 10ml acetone. After fully reacting for about 30 minutes, weigh 0.5g analytically pure zinc chloride and dissolve in 5mL water, and weigh 0.3g analytically pure sodium selenite into 5mL In the water, add the prepared zinc ion, selenium ion solution and 10ml analytically pure hydrazine hydrate (volume concentration 80%) into the mixed solvent, stir evenly, place in a 40ml stainless steel pressure-resistant reactor, and react at 160°C for 24h After centrifugal separation, washing and drying, the obtained precipitate is obtained as a yellow powder. The product was identified as zinc selenide by X-ray powder diffraction; its morphology was analyzed with a transmission electron microscope (TEM), and it was observed that its morphology was monodisperse nanoparticles with a particle size of 10-20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com