Internal expanding type electromagnetic brake

An electromagnetic brake, internal tensioning technology, applied to drum brakes, brake types, brake components, etc., can solve problems such as large structure size, easy wear of guide shafts, and electromagnetic attraction of brakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

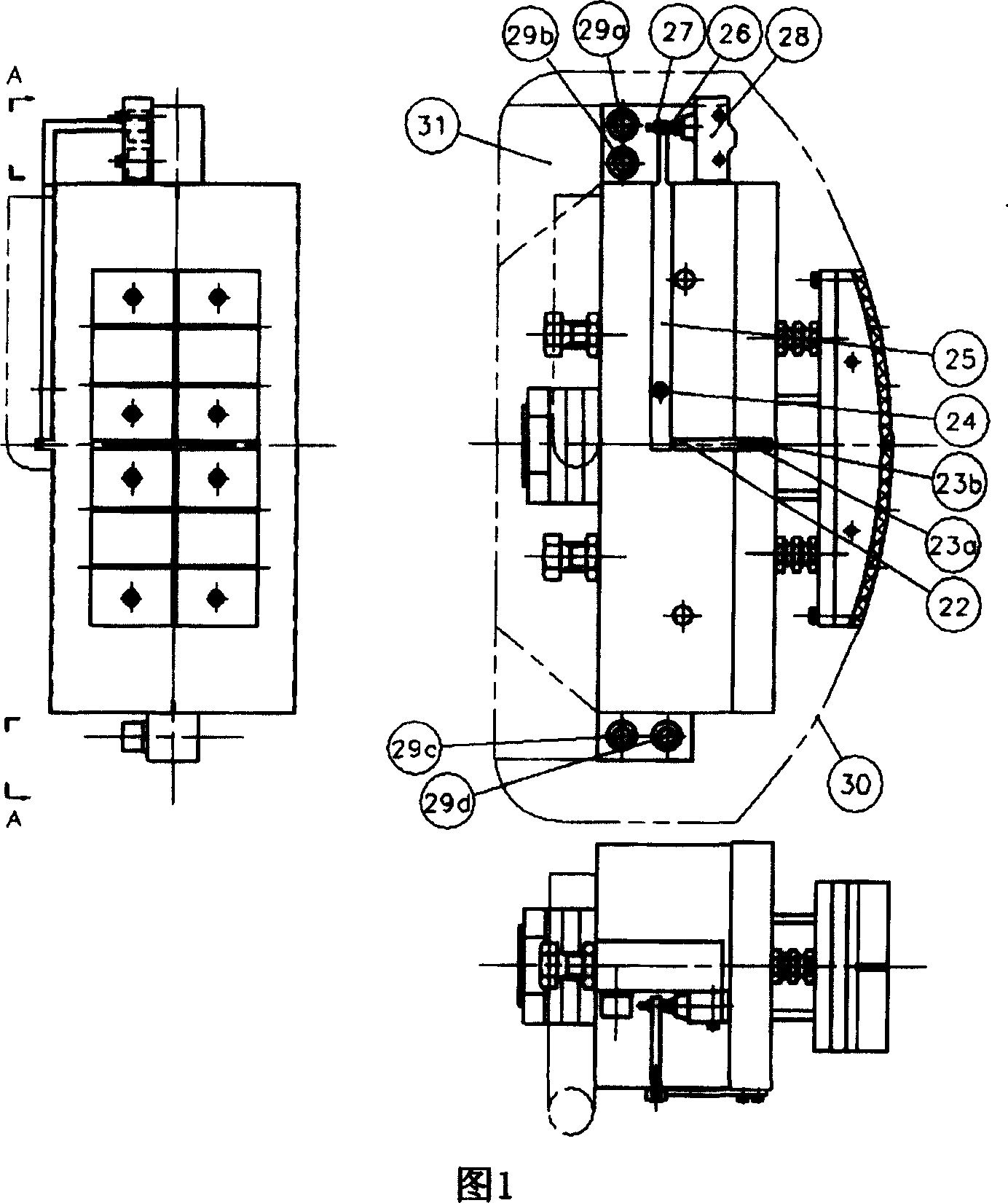

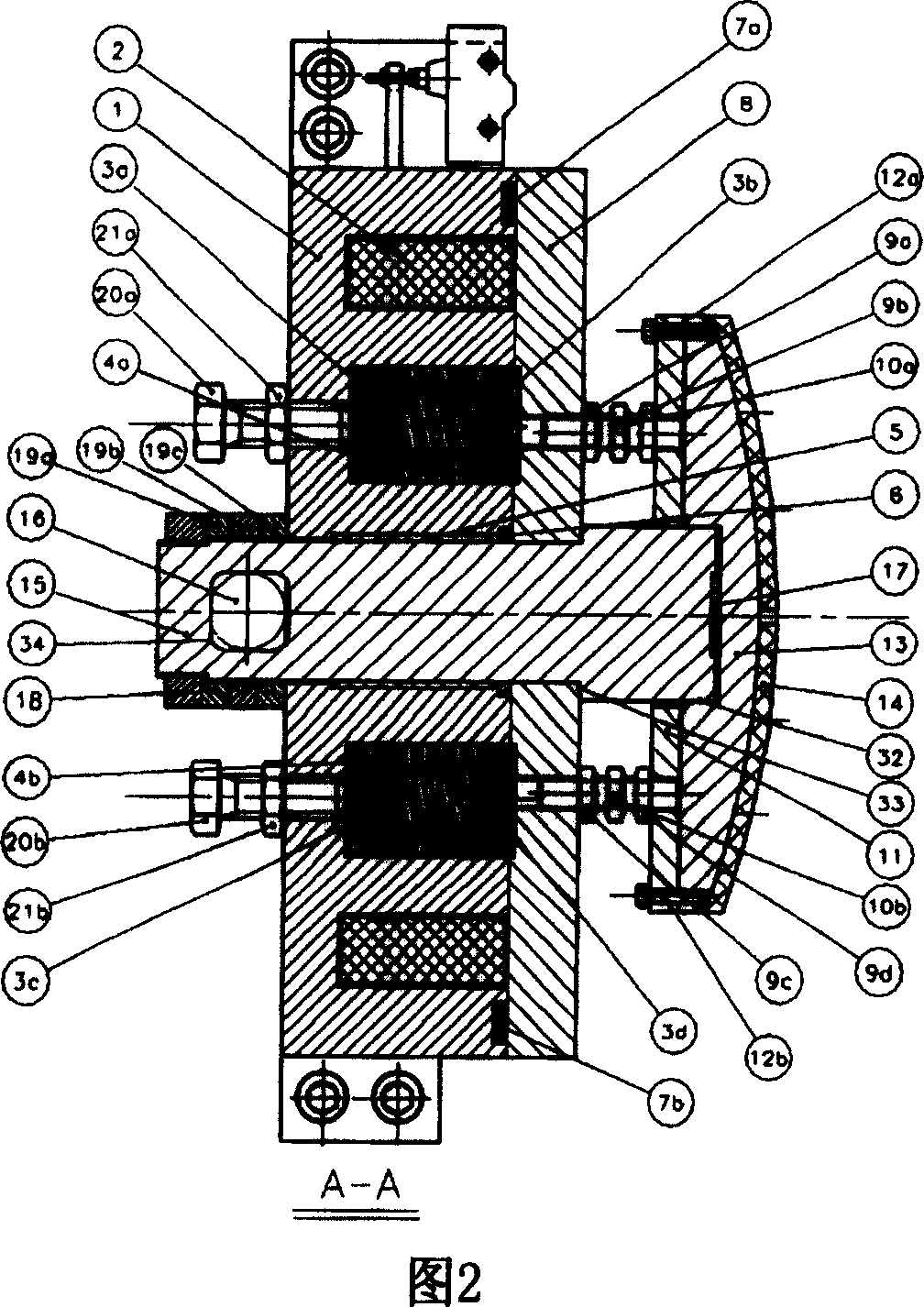

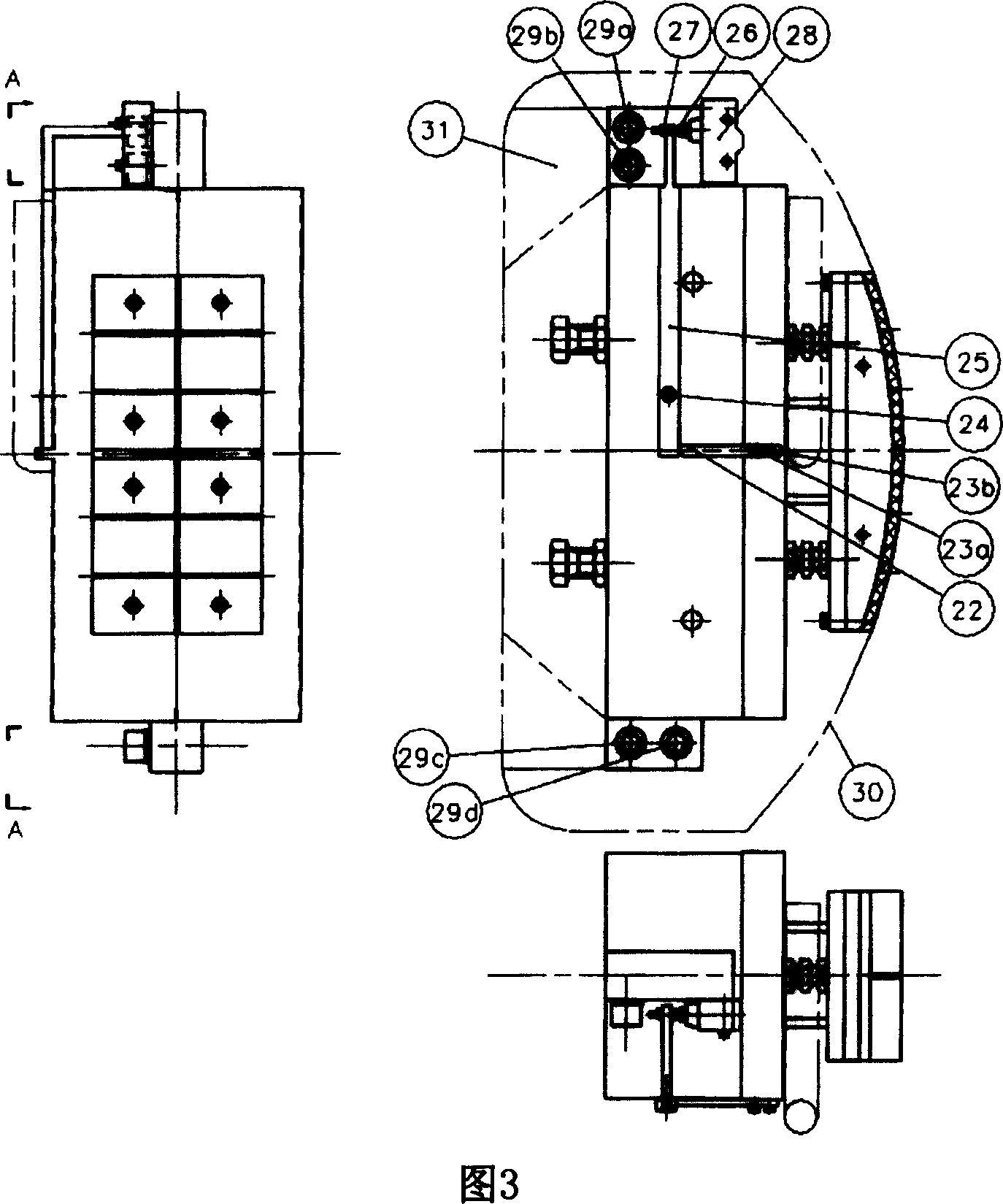

[0015] As shown in FIGS. 1 and 2 , the first embodiment of the internal tension electromagnetic brake of the present invention includes a fixed core 1 , a movable armature 8 , a coil 2 , brake shoes 13 , friction plates 14 , and a compression spring 4 .

[0016] It also includes a main shaft 15 which is arranged in the hole at the middle position of the fixed iron core 1 through the sliding bearing 5 and the bushing 6 . The sliding bearing 5 is a lubrication-free bearing, so the lubrication of the main shaft 15 need not be considered. The function of the shaft sleeve 6 is to prevent the sliding bearing 5 from being taken out of the fixed iron core 1. Therefore, the shaft sleeve 6 is installed on the side of the sliding bearing 5 in the hole of the fixed iron core 1. The shaft sleeve 6 and the hole of the fixed iron core 1 are tight. Cooperate.

[0017] The brake shoe 13 is provided with a rectangular opening 32 (see FIG. 5 ), through which the main shaft 15 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com