Permanent magnetic synchronous motor driven automatic escalator and method for implcmenting regular stopping distance requirement for automatic pavement (õ‘î´“ë

A technology for permanent magnet synchronous motors and moving walks, which is applied to escalators, transportation and packaging, etc., and can solve problems such as the inability to ensure that escalators and moving walks meet the requirements of the stopping distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

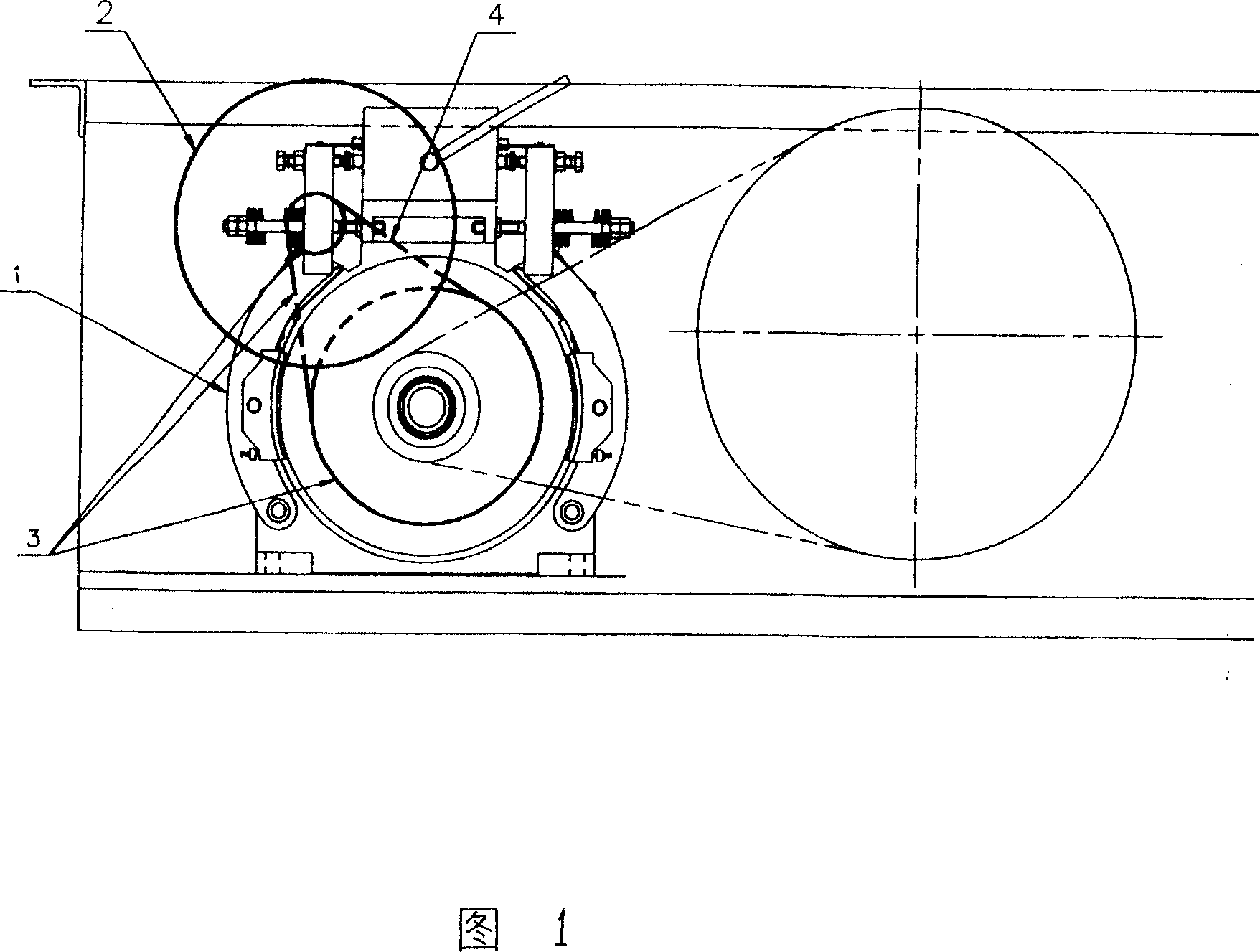

[0011] Referring to Fig. 1, the present invention realizes the stopping distance requirement by increasing the speed of the flywheel. A transmission pair 3 is installed between the shaft end of the permanent magnet synchronous motor 1 and the flywheel 2, shown as a transmission chain 4, to increase the speed of the flywheel 2, and then increase the inertia of the flywheel 2 converted to the brake shaft, that is, the motor shaft. Use a working brake braking torque to achieve the required stopping distance.

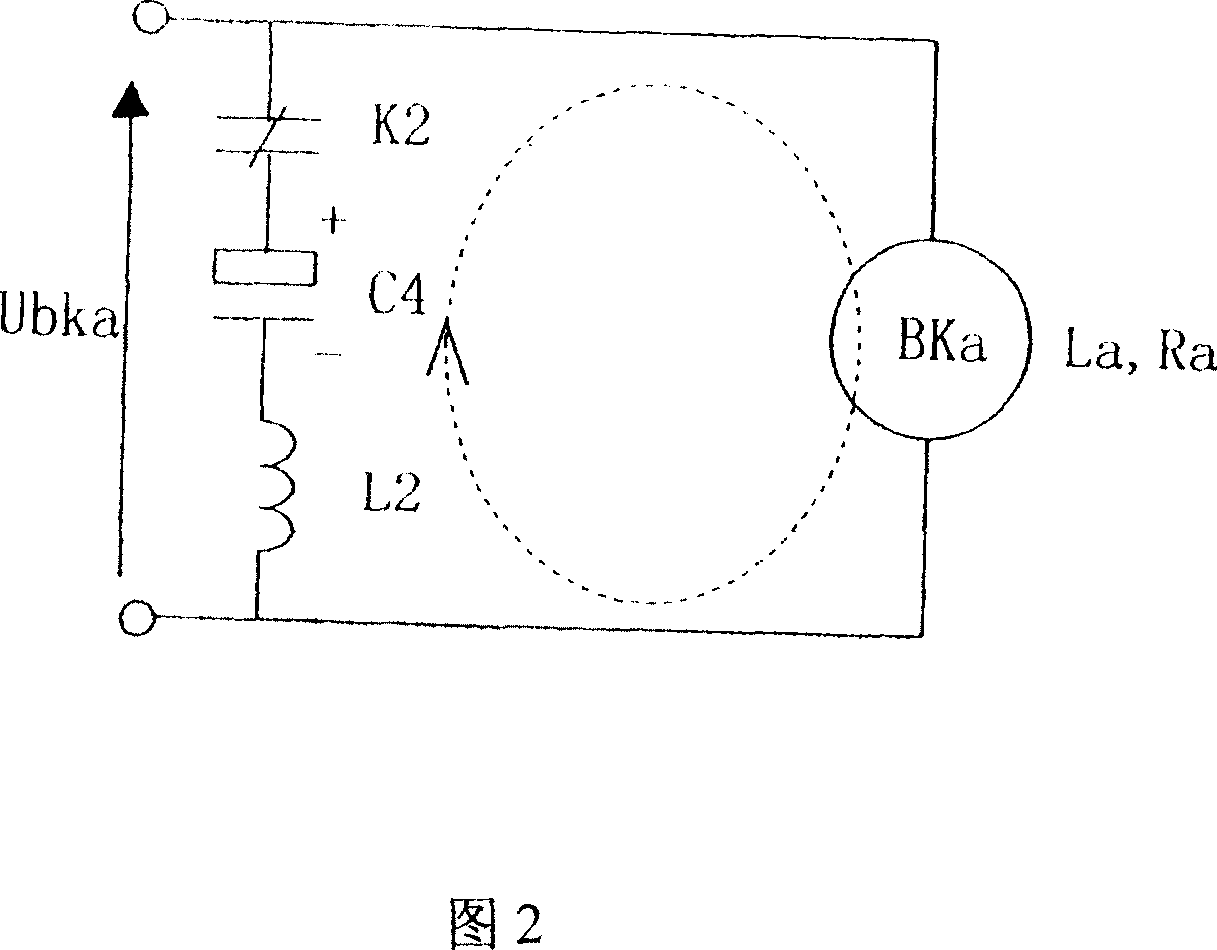

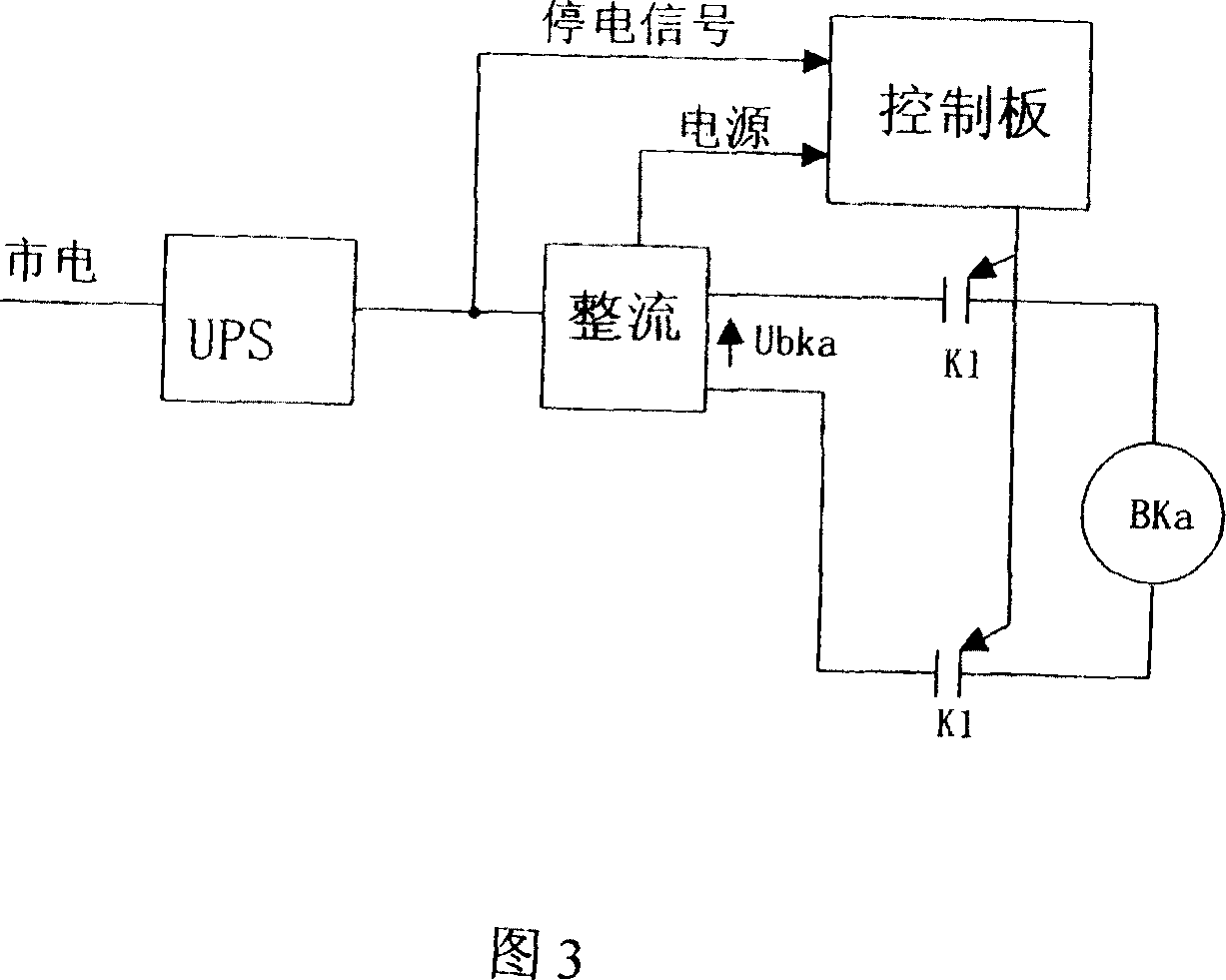

[0012] What Figure 2 describes is that the delay braking of the additional brake is realized by a capacitor circuit. In additional brake Bk a A capacitor C is connected in parallel at both ends of the 4 , its anode and relay K 2 The normally closed contact is connected, the negative pole is connected with the inductance L 2 connect. When the speed of the escalator or moving walk exceeds the set value (less than 1.4 times the rated speed) or reverses, the control board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com