Transformer with wound single unit

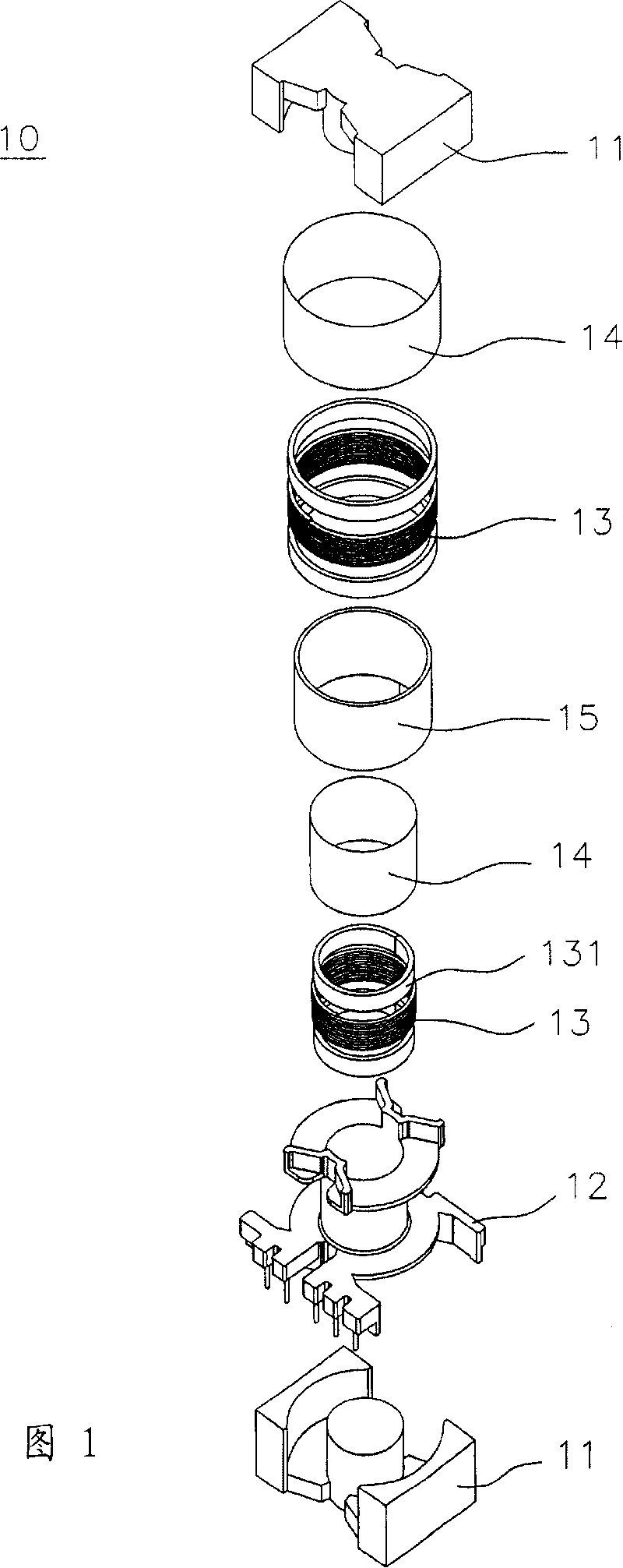

A transformer and wire winding technology, applied in the field of transformers, can solve the problems of bulky transformer circuit boards, reduce the service life of transformers, and unusable transformers, and achieve the effects of avoiding traditional heat accumulation that cannot be dissipated, increasing space, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

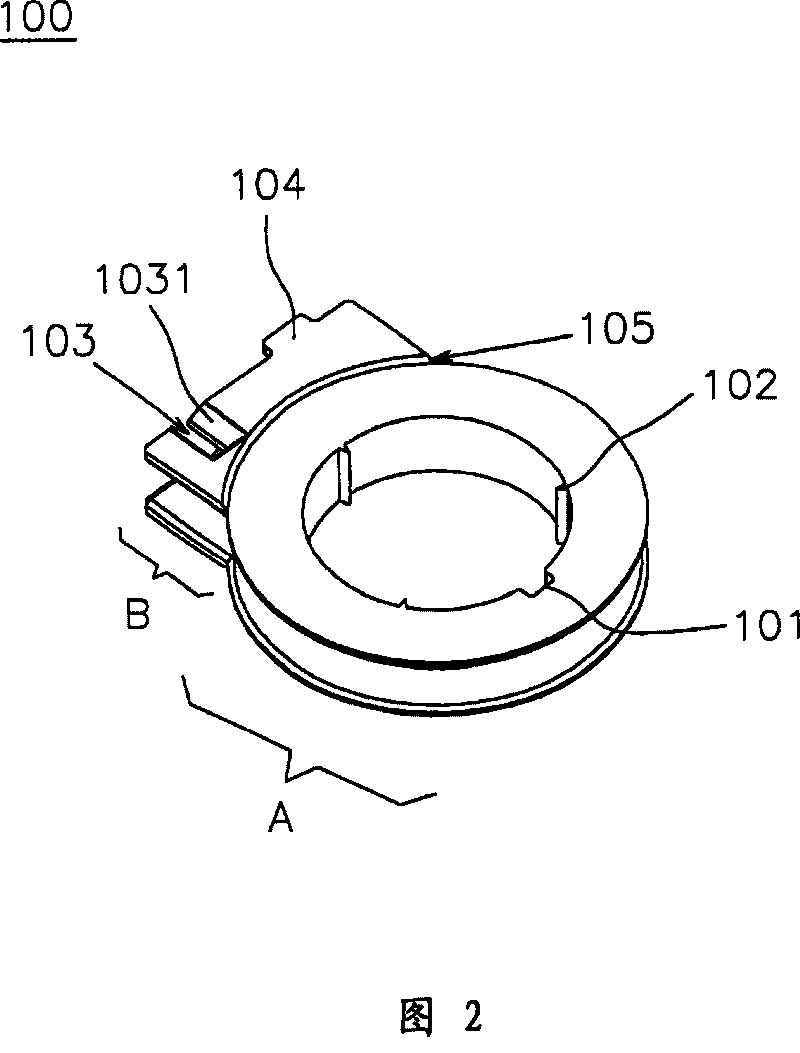

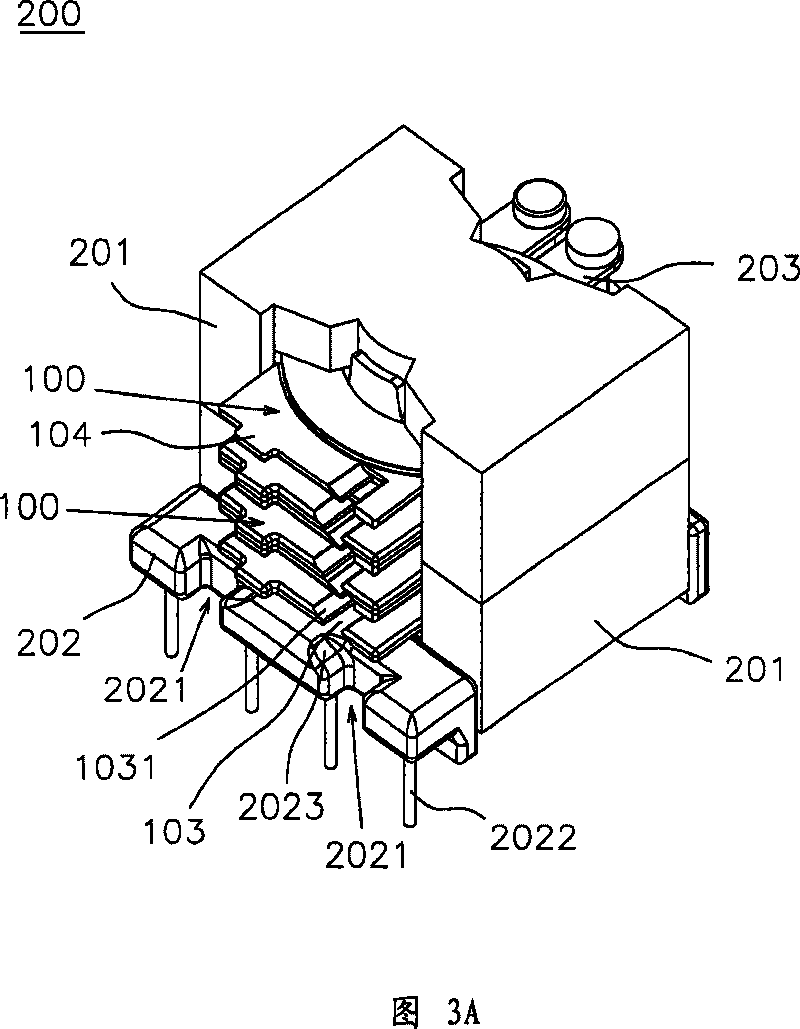

[0038] figure 2 It is a schematic diagram of the winding unit 100 of the present invention, the winding unit 100 includes a winding area A and a non-winding area B, wherein the winding area A can be surrounded by a wire (not shown) On the other hand, each turn of the wire is arranged on a substantially same plane to reduce the stacking height of the transformer 200, and the wire may be a triple-layer insulated wire. Such as figure 2 As shown, the transverse end surface of the winding area A and the transverse end surface of the non-winding area B are located on different planes, and the winding area A has a first engaging portion 101 and at least one protrusion 102 . The first engaging portion 101 can facilitate the winding unit 100 to pass through an opposite external base, and the raised strip 102 can increase the distance between the winding unit 100 and the external base. Tight fit, and can absorb excessive stress and strain, so that the combination of the two will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com