Method for producing biomass carbonized gas and back fire-biomass carbonated gas generating stove

A biomass charcoal and gas generation technology, which is applied in the fields of biofuels, coke ovens, special forms of dry distillation, etc., to achieve the effect of saving energy, reducing the diameter of gas pipes, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

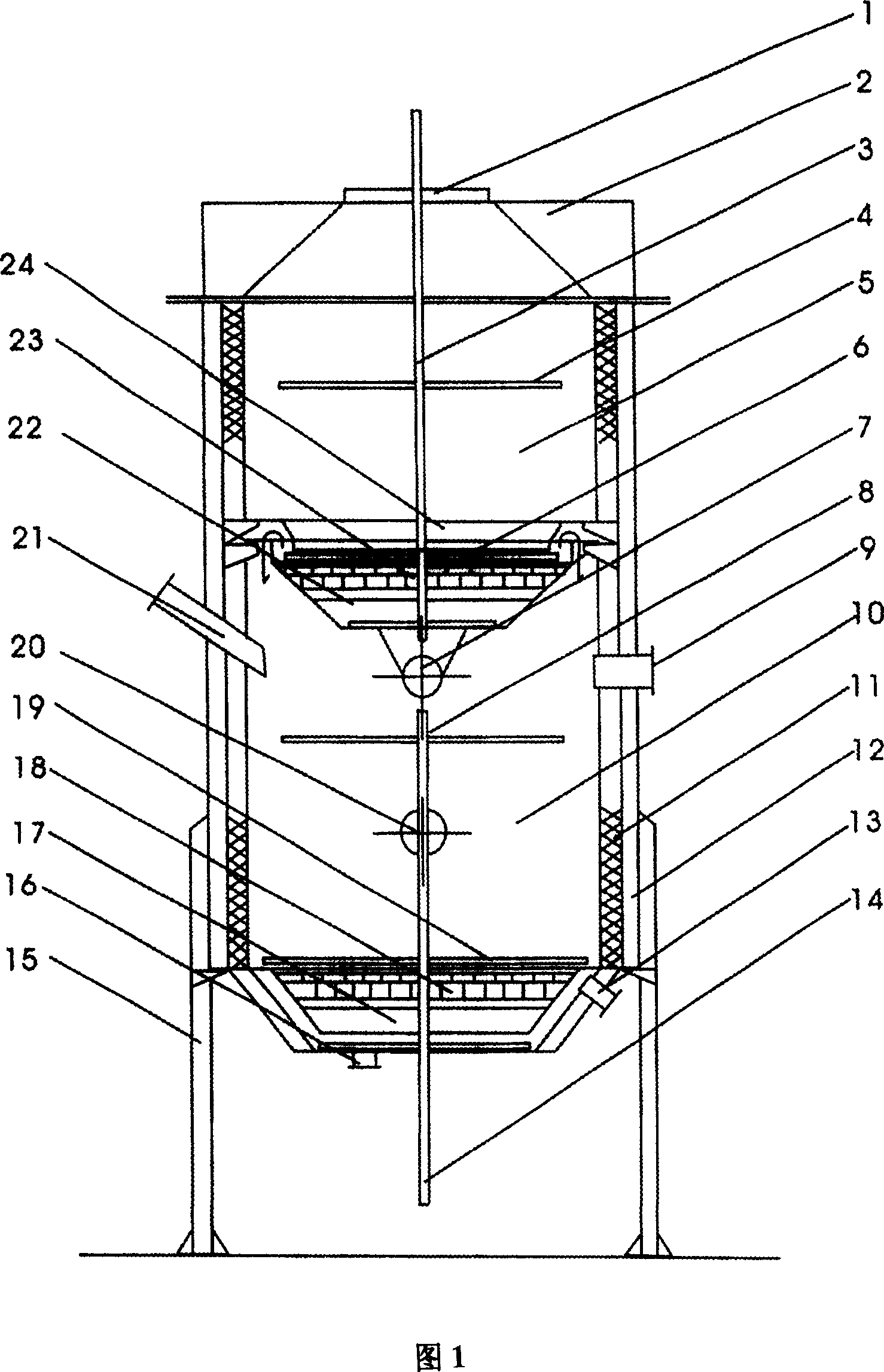

Embodiment 1

[0020] Using corn stalks and sorghum stalks as the main raw materials, after being chopped according to the above process, the dust and waste materials that do not meet the requirements for carbonization materials are screened and removed, and then the moisture content is controlled at 15% after drying and dehydration. Put into the lower carbonization furnace cavity 10 in the above-mentioned furnace with a height of 8.9 meters and an inner diameter of 3 meters, and add the undersieve straw fines and other agricultural and forestry wastes that are not suitable for carbonization materials into the upper layer of the furnace for gasification after processing. Ignite in the furnace chamber 5, start the suction fan to suck the air (gasification agent) from the furnace upper feeding port 1 into the furnace upper backfire gasification furnace chamber 5 and perform gasification reaction with the gasification material to generate 300-500°C The combustible gas is sucked out of the furnac...

Embodiment 2

[0023] Using branches and cotton stalks as the main raw materials, after chopping according to the above process, screen and remove the dust and waste that does not meet the requirements for carbonization materials, and then dry and dehydrate, control the moisture content at 15%, and then add high 9.6 In the lower carbonization chamber 10 of the above-mentioned furnace with an inner diameter of 3.6 meters, the above-mentioned fine materials such as undersieves, branches, cotton stalks and other agricultural and forestry wastes that are not suitable for carbonization materials are added to the upper layer of the furnace after processing. Fire is ignited in the gasification furnace chamber 5, and the suction fan is started to suck the air (gasification agent) into the upper backfire gasification chamber 5 of the furnace from the charging port 1 on the furnace to carry out the gasification process with the gasification material in the gasification furnace chamber. The gasification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com