Refrigerant supplying device

A technology for supplying devices and refrigerants, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as time-consuming, and achieve the effect of preventing excessive pressure rise, ensuring providing action, and efficient action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

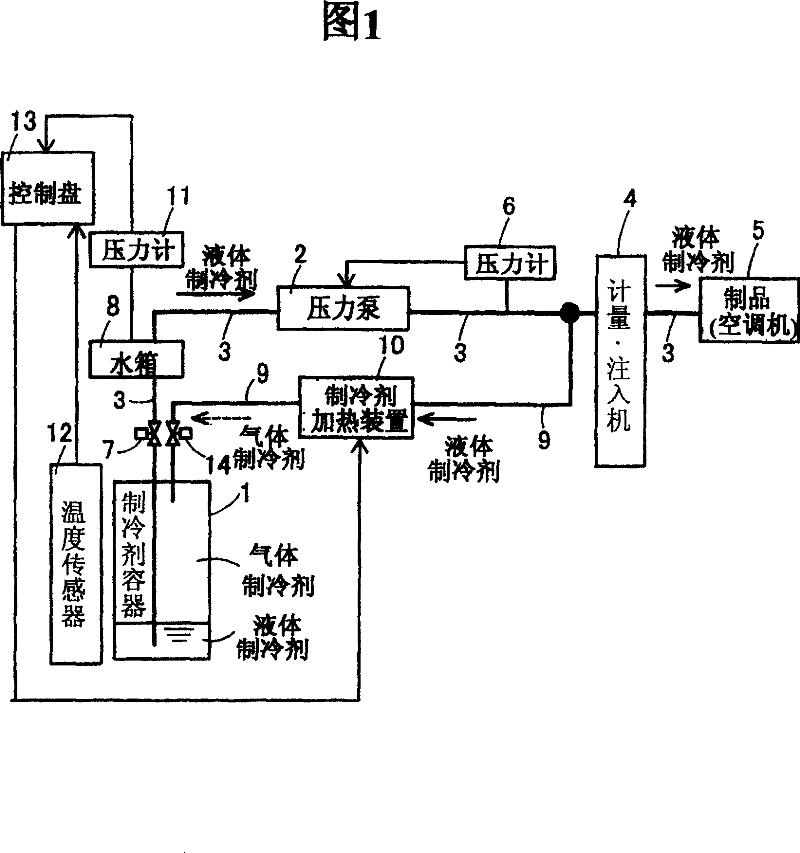

[0036] Hereinafter, an embodiment of the refrigerant supply device according to the present invention will be described in detail with reference to the drawings.

[0037] FIG. 1 shows a schematic configuration diagram of a refrigerant supply device according to this embodiment. In this refrigerant supply device, the liquid refrigerant in the refrigerant container 1 is pumped by the pressure pump 2, passes through the supply pipe 3 and the metering / injecting machine 4, and is supplied and filled to a product (air conditioner) 5 as consumer equipment. The refrigerant supply device has a first pressure gauge 6 for measuring the pressure (discharge pressure) of the liquid refrigerant in the supply pipe 3 on the downstream side of the pressure pump 2 . The discharge pressure measured by the first pressure gauge 6 is sent to the pressure pump 2 as a control signal. In this embodiment, when the discharge pressure measured by the first pressure gauge 6 is lower than a predetermined s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com