Self-adaptable straight-vaned pitch variable water turbine for tidal energy conversion

A water turbine and self-adaptive technology, applied in the direction of reaction engines, hydroelectric power generation, mechanical equipment, etc., can solve the problems of complex mechanism and high cost of the blade swing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

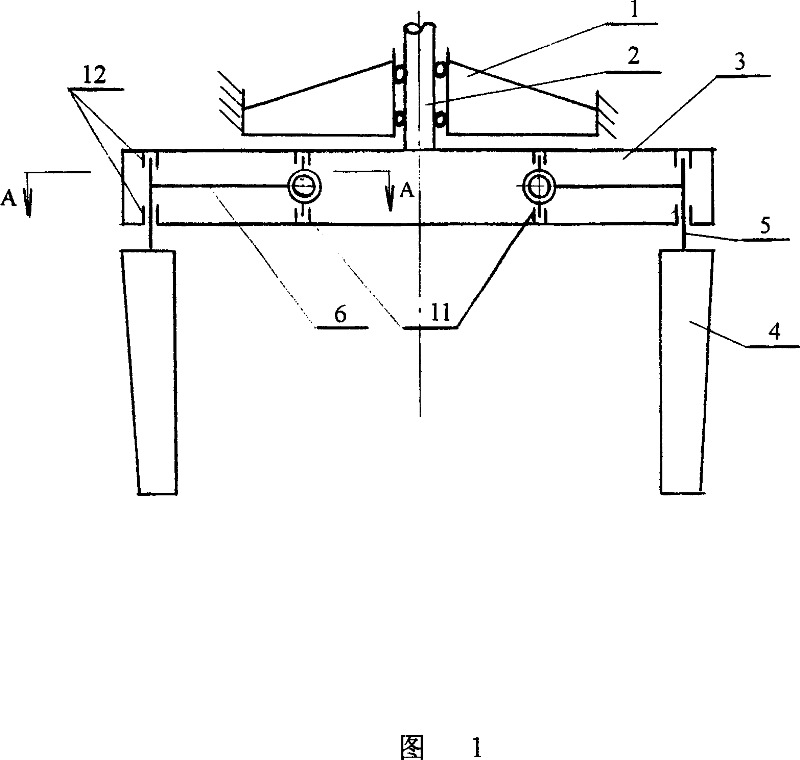

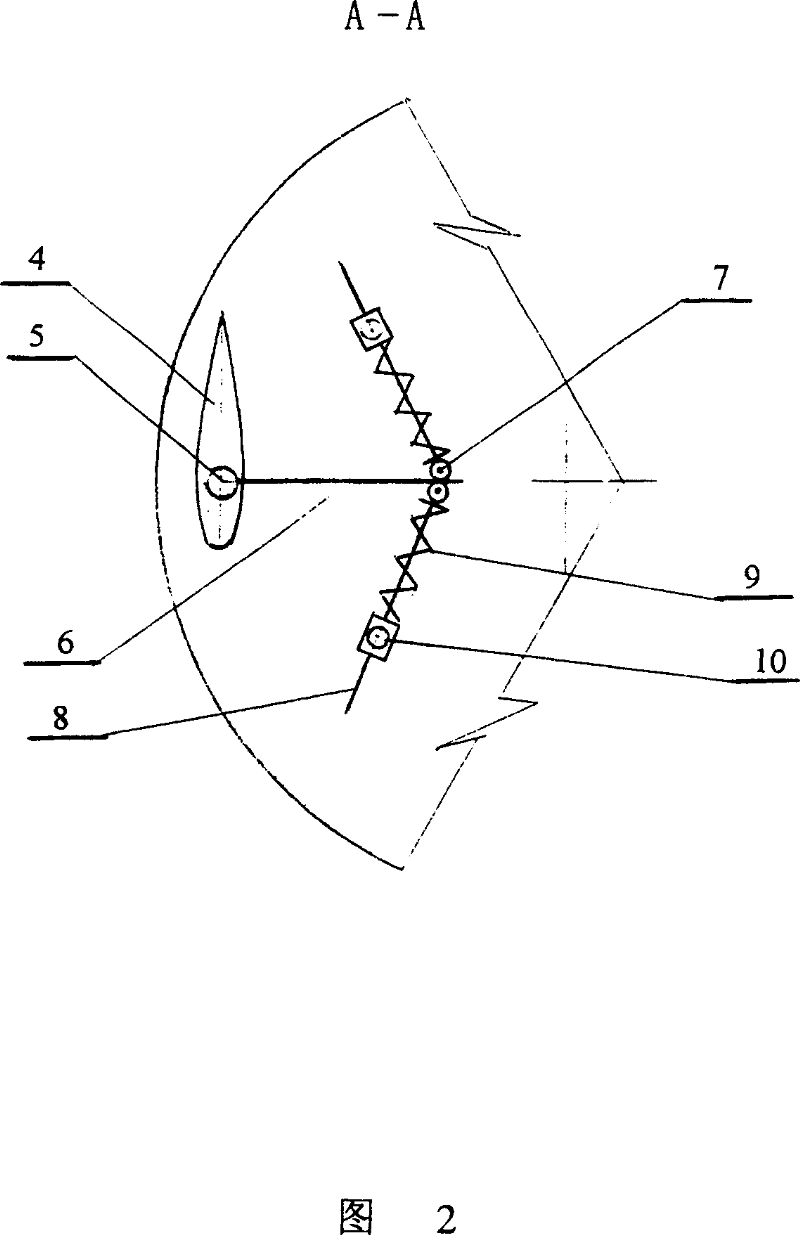

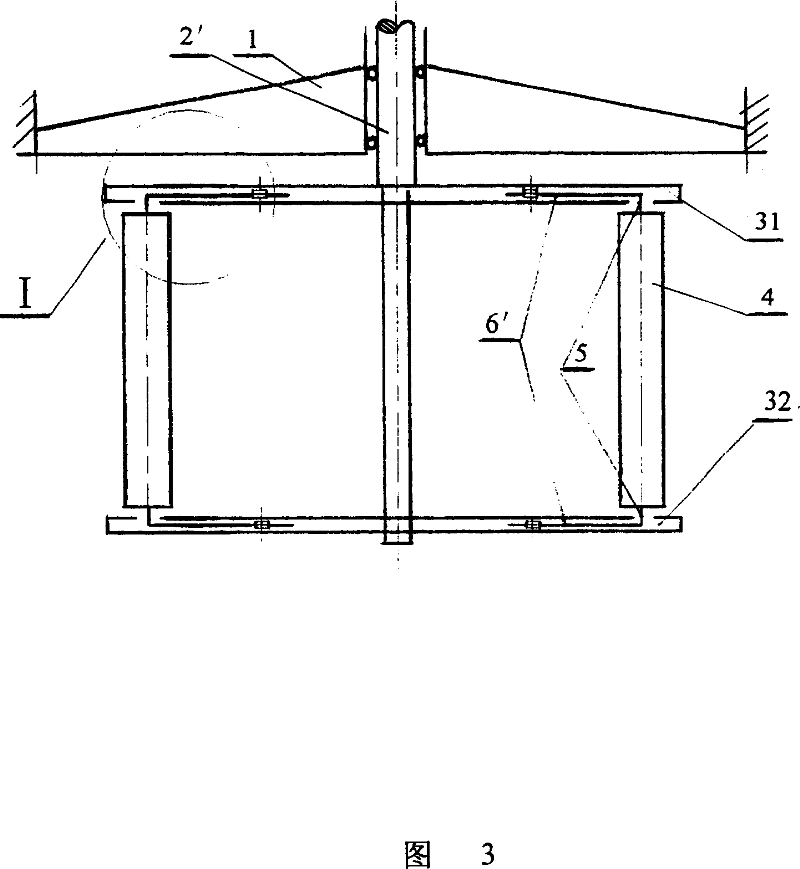

[0016] Two preferred schemes for the implementation of the present invention are given below and described in conjunction with the accompanying drawings.

[0017] The first technical scheme of the straight-blade self-adaptive variable-pitch water turbine used for tidal current energy conversion is shown in Figures 1 and 2, which is to use a coil spring to control the angle of attack of the blades, which includes a set of turbine frame (1), a root main shaft (2), a turntable box (3), several blades (4), blade shafts (5) and matching blade bearing seats (12), swing rods (6), hinge supports (7), Guide rod (8), coil spring (9), sliding sleeve (10) and sliding sleeve seat (11). Wherein, the circular and hollow turntable box (3) with rectangular cross-section is inserted into the bearing in the hydraulic turbine base (1) by means of the fixed main shaft (2) at the central axis, and can freely rotate around the central axis. A plurality of trapezoidal or rectangular straight-leaf bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com