A reciprocating wind power generation system

A wind power generation system, reciprocating technology, applied in the direction of wind power generation, wind engine, wind motor combination, etc., can solve problems such as high difficulty, increase system complexity, high cost, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

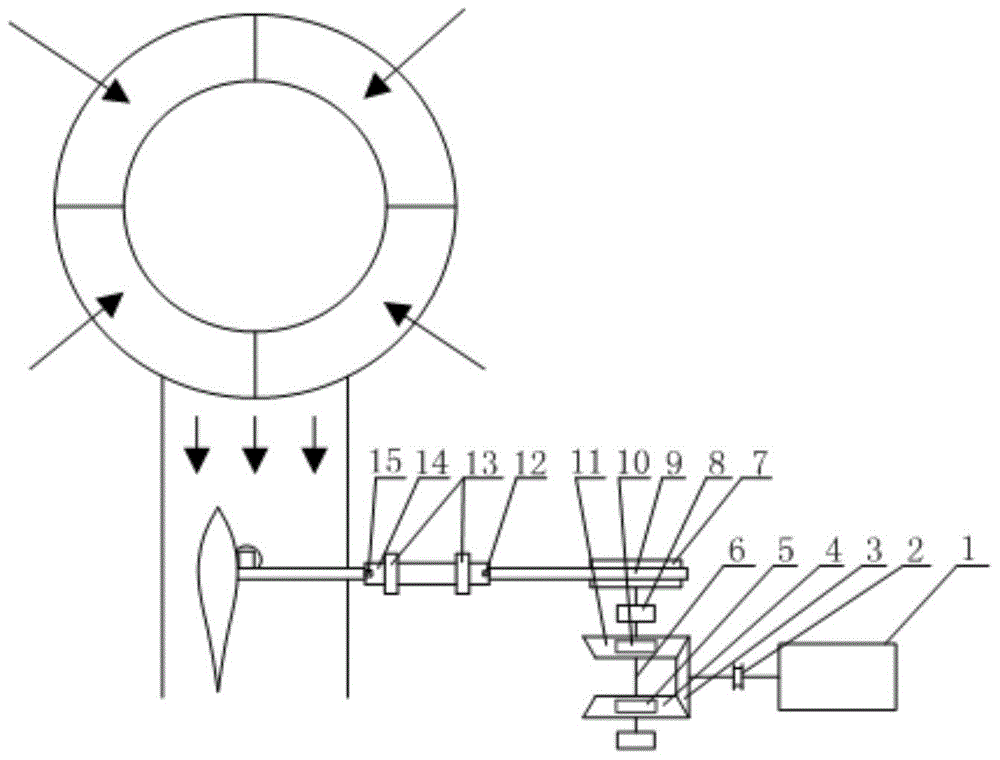

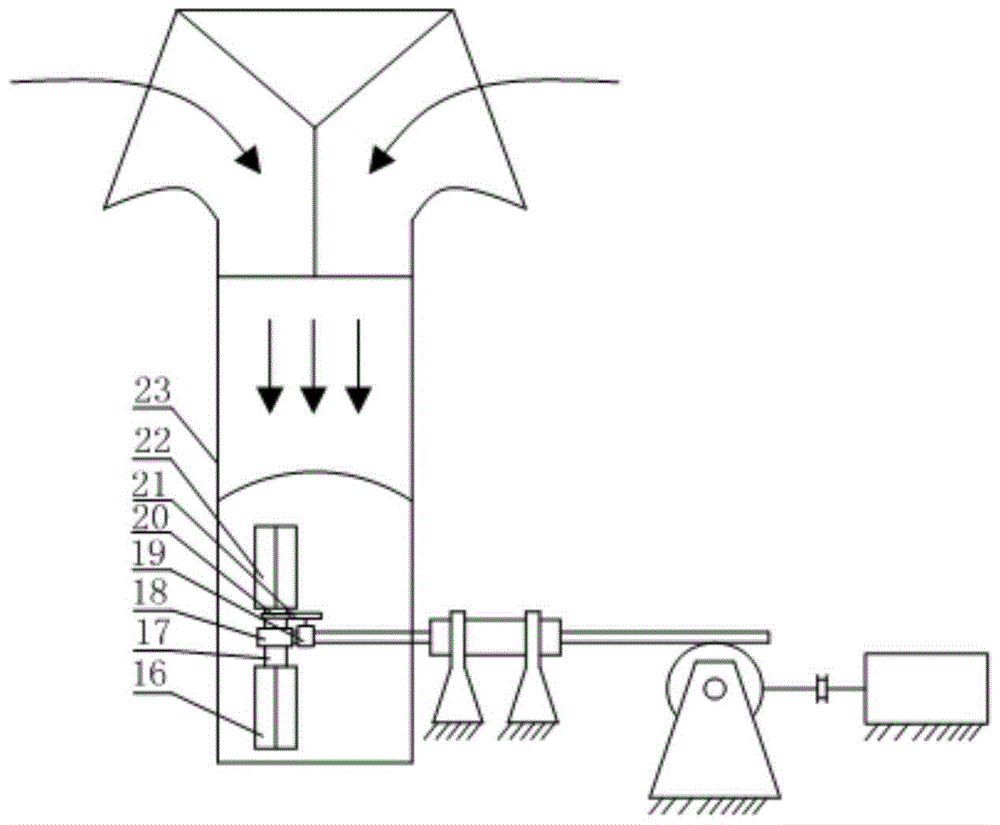

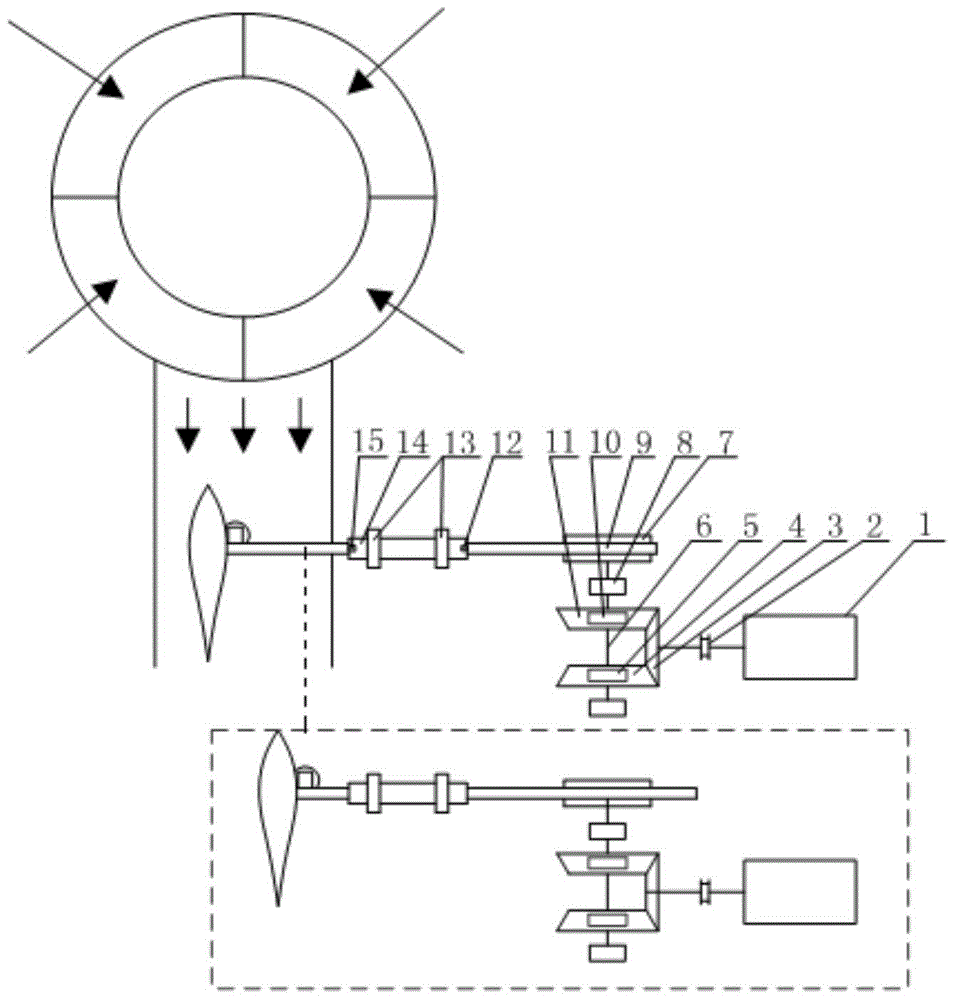

[0028] Such as figure 1 , figure 2 As shown, the wind collector 23 collects the wind energy in the atmosphere, as shown by the arrow line in the figure, the collected wind energy is blown to the upper blade 22 and the lower blade 16, and the upper blade 22 and the lower blade 16 are connected by the blade shaft 17, and the blade shaft 17 is connected to the lower blade 16. The blade bearing 18 is connected, and the blade bearing 18 is connected with the rack 9; the pitch motor 19 is installed on the rack 9, and the pitch motor 19 drives the blade shaft gear 21 to rotate through the pitch reducer 20, thereby realizing the upper blade 22 and the lower blade 16 The direction of the rack 9 is changed, and then the moving direction of the rack 9 is changed to realize the reciprocating motion of the rack 9; the rack 9 is installed in the sleeve 14, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com