Horizontal-shaft wind turbine with rotating cylinder at front edge of paddle

A horizontal axis, wind turbine technology, applied in the field of wind turbines, can solve the problems of the maximum lift-to-drag ratio limitation, fixed-pitch wind turbines are prone to stall, etc., and achieve the effect of increasing the lift-to-drag ratio and improving the utilization rate of wind energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

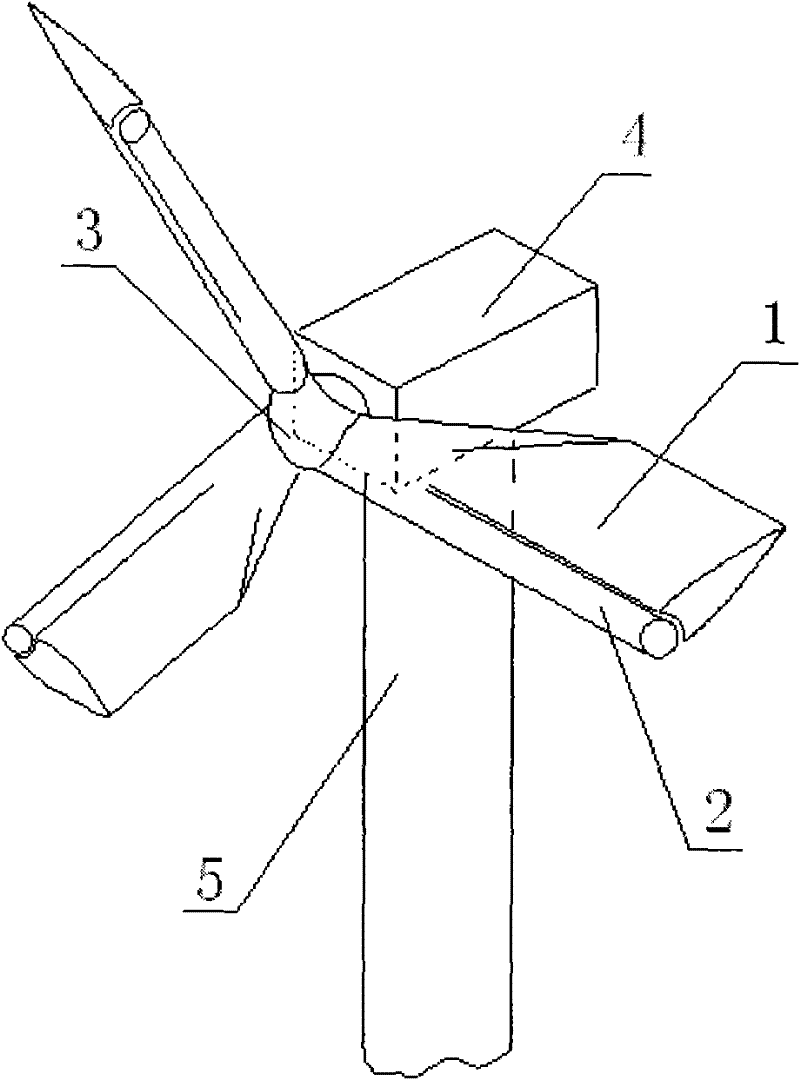

[0023] Embodiment one: see figure 1 , the horizontal axis wind turbine with a rotating cylinder at the leading edge of the blade, including a tower 5, a horizontal axis chassis 4 installed on the top of the tower 5, a hub 3 located at the front end of the chassis 4, and a blade 1 fixedly installed on the hub 3 The front edge of each blade 1 is equipped with a controllable rotating cylinder 2 that rotates forward or in a direction around its own axis, and the rotating cylinder 2 and the blade 1 rotate together with the hub 3 around the horizontal axis of the wind turbine.

Embodiment 2

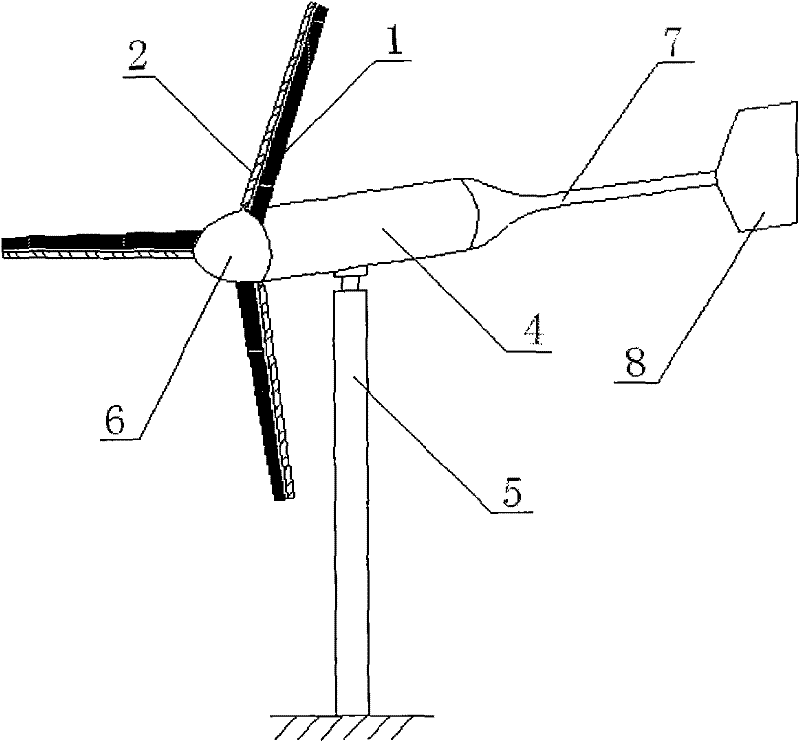

[0024] Embodiment two: see figure 2 , the horizontal axis wind turbine with a rotating cylinder at the leading edge of the blade, including a vertically installed tower 5, a horizontal axis chassis 4 installed on the top of the tower 5, a tail boom 7 and an empennage 8 at the rear of the chassis 4 1. The paddle 1 and the shroud 6 located at the front end of the chassis 4, each paddle 1 front edge is equipped with a controllable rotating cylinder 2 that rotates forward or reverse around its own axis, and the rotating cylinder 2 is connected with the paddle 1 Together with the rotor 14 in the box 4, it rotates around the horizontal axis of the wind turbine.

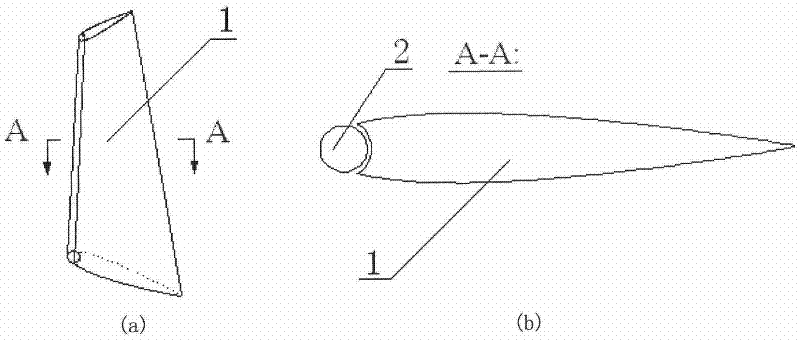

[0025] exist figure 1 , 2 , there is a certain gap δ between the blade 1 and the rotating cylinder 2 at its leading edge. δ is about 1 mm to 2 cm, depending on the size of the wind turbine, to ensure that the rotating cylinder 2 rotates independently around its own axis relative to the blade 1, such as image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com