Air energy turbine type hot-air engine

A hot air engine and air energy technology, which is applied to combined engines, engine components, machines/engines, etc., can solve the problems of low effective utilization rate, exhaust gas emission, and cumbersome machines, so as to achieve improved effective utilization rate, simple overall structure, Effects of controlling power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

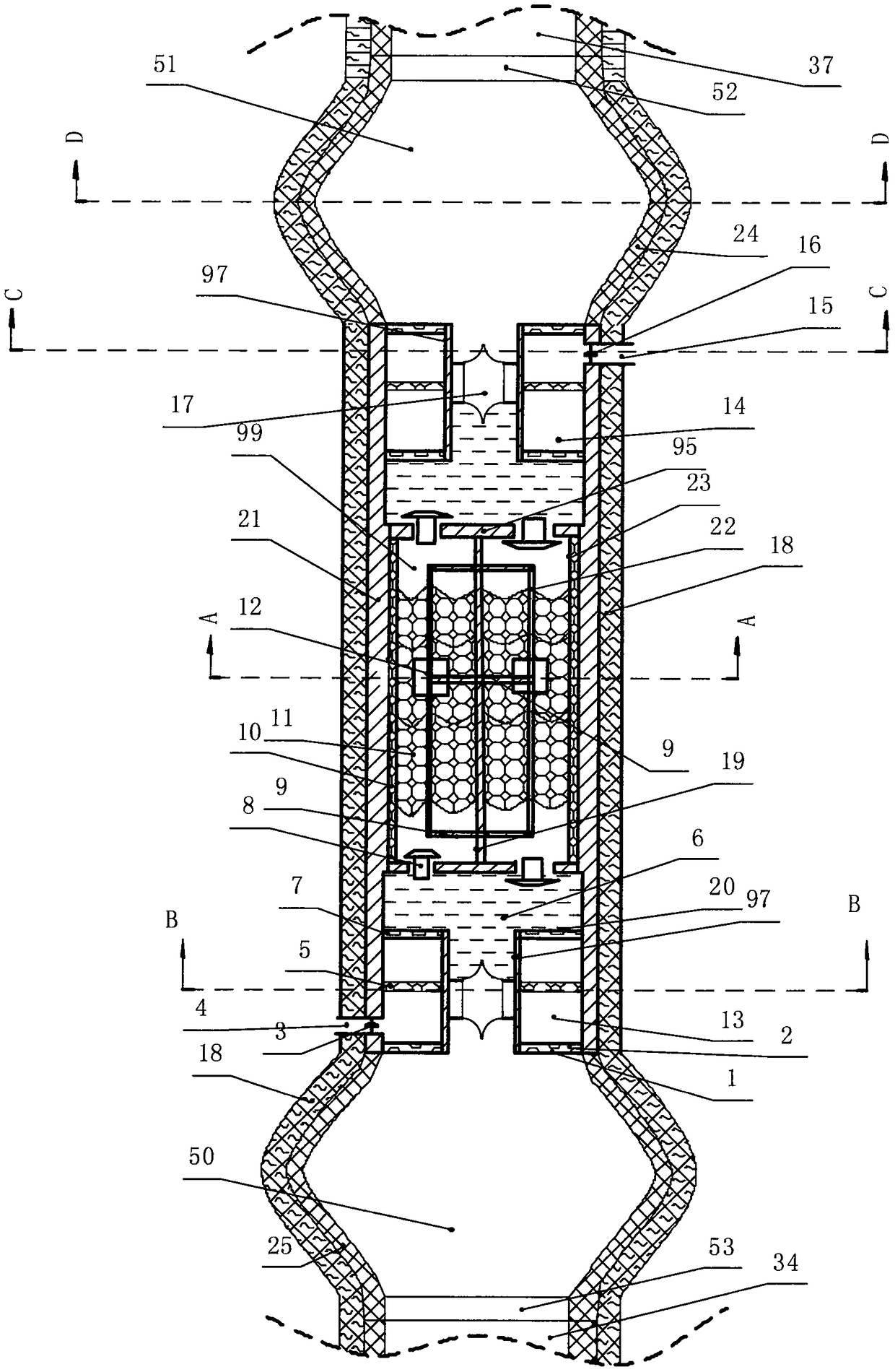

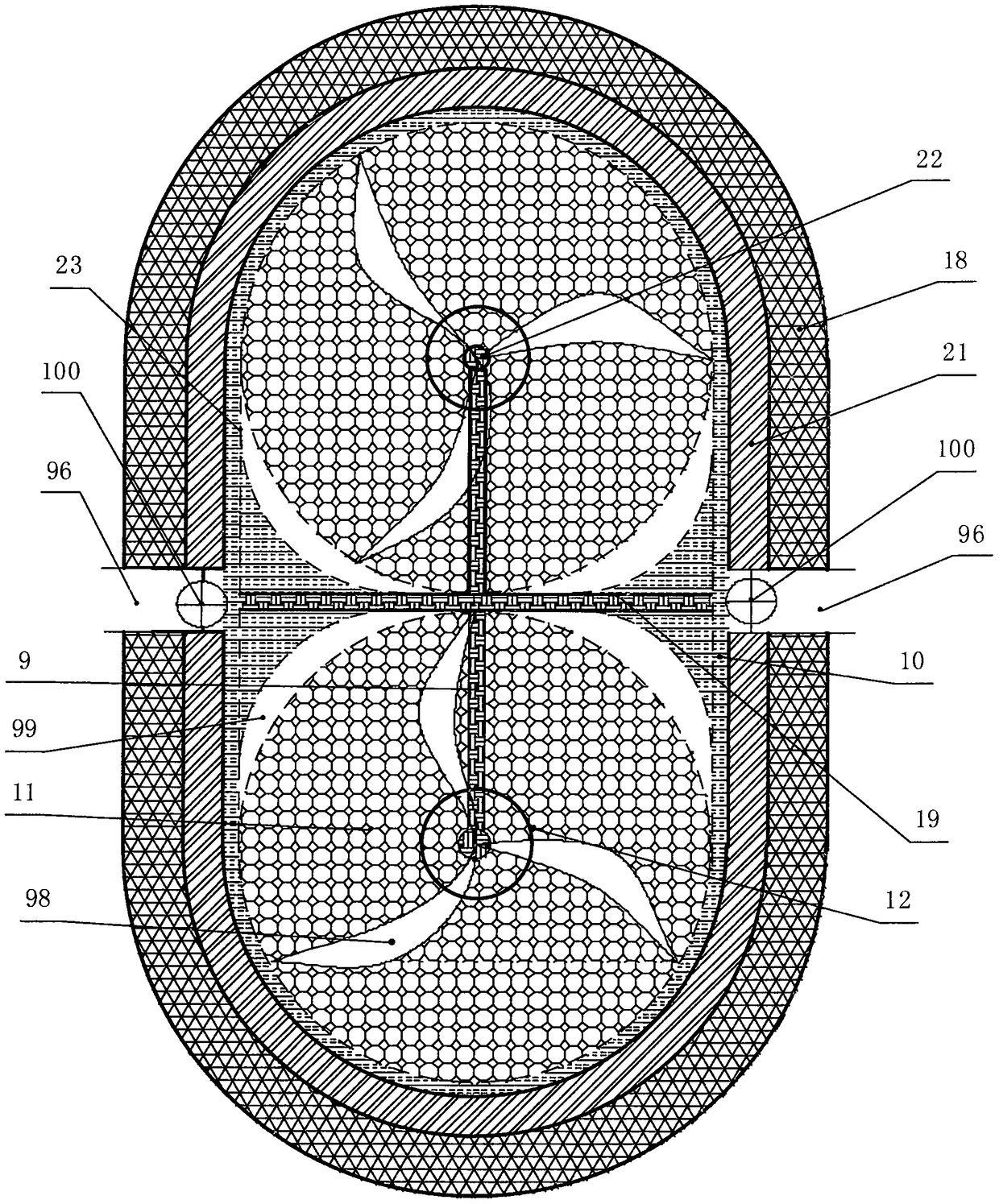

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

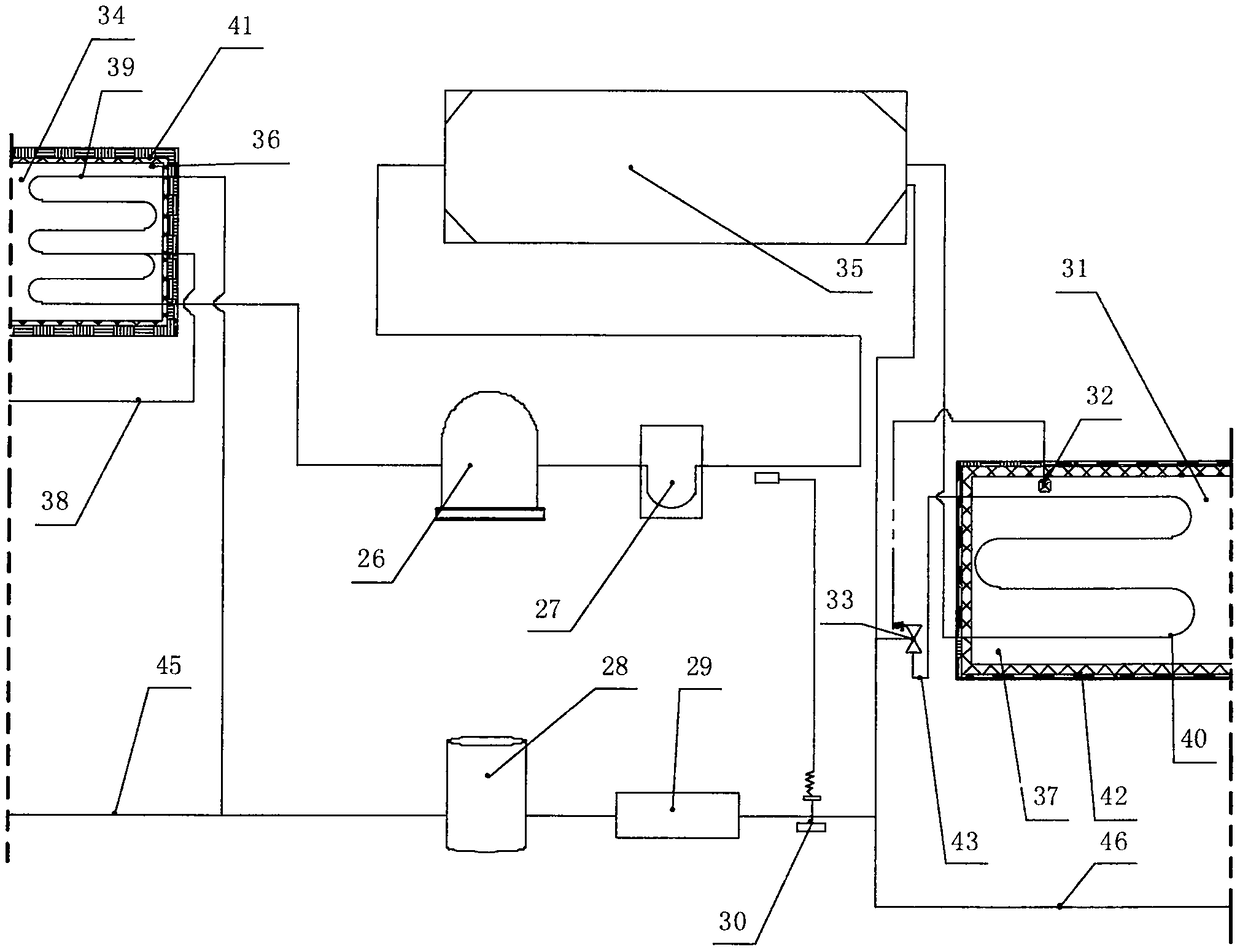

[0029] The novel air energy heater of the present invention is mainly composed of six parts: an air energy heating mechanism, a thermal chamber 34, a cooling chamber 37, an airflow mechanism, an airflow return mechanism and a turbine driving mechanism. The concrete structure of force chamber 37 is as figure 1 As shown, the air energy heating device is mainly composed of a compressor 26, a gas-liquid separator 27, an evaporator 35, an expansion valve 30, a filter 29, and a liquid storage tank 28 connected in series through pipelines. The above-mentioned compressor 26, gas-liquid separation The working principle of the device 27, the evaporator 35, the expansion valve 30, the filter 29 and the liquid storage tank 28 is the same as that of the existing air energy water heater, and will not be repeated here.

[0030] Thermal chamber 34 comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com