The Role of Semiconductors in Potassium-Sulfur Battery Efficiency

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Semiconductor-Enhanced K-S Battery Background and Objectives

Potassium-sulfur (K-S) batteries have emerged as promising candidates for next-generation energy storage systems due to their theoretical high energy density, cost-effectiveness, and environmental friendliness. The evolution of this technology can be traced back to the early 2010s when researchers began exploring alternatives to lithium-ion batteries to address concerns related to lithium scarcity and cost. Potassium, being abundant in the Earth's crust (2.1% compared to lithium's 0.006%), presents a sustainable alternative for large-scale energy storage applications.

The technical trajectory of K-S batteries has been marked by significant challenges, particularly related to the insulating nature of sulfur, shuttle effect of polysulfides, and volume expansion during cycling. These limitations have historically restricted the practical implementation of K-S batteries despite their theoretical advantages. The introduction of semiconductors as functional components represents a pivotal advancement in addressing these fundamental issues.

Semiconductors in K-S battery systems serve multiple critical functions: enhancing electron transport pathways, catalyzing redox reactions, and providing structural stability to accommodate volume changes. The integration of semiconductor materials began gaining traction around 2018, with early research focusing primarily on carbon-based semiconductors before expanding to include metal oxides, sulfides, and advanced 2D materials like MXenes and transition metal dichalcogenides.

The technical objectives for semiconductor-enhanced K-S batteries center on achieving practical energy densities exceeding 300 Wh/kg, cycle life beyond 1000 cycles, and coulombic efficiencies consistently above 99%. Additionally, researchers aim to develop systems that maintain performance at high charge/discharge rates (>2C) and operate effectively across wide temperature ranges (-20°C to 60°C) to meet diverse application requirements.

Current research trends indicate a shift toward rational design of semiconductor interfaces and hierarchical structures that can simultaneously address multiple performance bottlenecks. Particular emphasis is being placed on developing semiconductors with tailored band structures that facilitate electron transfer while inhibiting polysulfide shuttling through both physical and chemical mechanisms.

The anticipated technological evolution suggests that semiconductor-enhanced K-S batteries could reach commercial viability within the next 5-7 years, potentially revolutionizing grid-scale energy storage and electric vehicle applications. This timeline aligns with global sustainability initiatives and the increasing demand for high-performance, cost-effective energy storage solutions that can support renewable energy integration and electrification of transportation.

The technical trajectory of K-S batteries has been marked by significant challenges, particularly related to the insulating nature of sulfur, shuttle effect of polysulfides, and volume expansion during cycling. These limitations have historically restricted the practical implementation of K-S batteries despite their theoretical advantages. The introduction of semiconductors as functional components represents a pivotal advancement in addressing these fundamental issues.

Semiconductors in K-S battery systems serve multiple critical functions: enhancing electron transport pathways, catalyzing redox reactions, and providing structural stability to accommodate volume changes. The integration of semiconductor materials began gaining traction around 2018, with early research focusing primarily on carbon-based semiconductors before expanding to include metal oxides, sulfides, and advanced 2D materials like MXenes and transition metal dichalcogenides.

The technical objectives for semiconductor-enhanced K-S batteries center on achieving practical energy densities exceeding 300 Wh/kg, cycle life beyond 1000 cycles, and coulombic efficiencies consistently above 99%. Additionally, researchers aim to develop systems that maintain performance at high charge/discharge rates (>2C) and operate effectively across wide temperature ranges (-20°C to 60°C) to meet diverse application requirements.

Current research trends indicate a shift toward rational design of semiconductor interfaces and hierarchical structures that can simultaneously address multiple performance bottlenecks. Particular emphasis is being placed on developing semiconductors with tailored band structures that facilitate electron transfer while inhibiting polysulfide shuttling through both physical and chemical mechanisms.

The anticipated technological evolution suggests that semiconductor-enhanced K-S batteries could reach commercial viability within the next 5-7 years, potentially revolutionizing grid-scale energy storage and electric vehicle applications. This timeline aligns with global sustainability initiatives and the increasing demand for high-performance, cost-effective energy storage solutions that can support renewable energy integration and electrification of transportation.

Market Analysis for Advanced K-S Battery Technologies

The potassium-sulfur (K-S) battery market is experiencing significant growth potential as energy storage demands increase globally. Current market analysis indicates that K-S batteries are positioned to capture substantial market share in the stationary energy storage sector, particularly as alternatives to lithium-ion technologies become more critical due to resource constraints and geopolitical considerations.

The global energy storage market is projected to grow at a compound annual growth rate of 20-25% through 2030, with grid-scale storage representing the largest segment. Within this landscape, K-S batteries are emerging as promising contenders due to their theoretical energy density of approximately 1675 Wh/kg, which exceeds many competing technologies. The cost advantage of potassium and sulfur raw materials—both abundant elements—provides a compelling economic case for widespread adoption.

Market segmentation reveals three primary application areas for advanced K-S battery technologies: utility-scale energy storage, industrial power management, and renewable energy integration. The utility sector currently represents the largest potential market, driven by grid modernization initiatives and the increasing penetration of intermittent renewable energy sources requiring storage solutions.

Regional market analysis shows Asia-Pacific leading K-S battery development and implementation, with China, Japan, and South Korea making substantial investments in research and manufacturing capacity. Europe follows closely, motivated by aggressive decarbonization targets and energy independence goals. North America shows growing interest, particularly in applications requiring long-duration energy storage.

Consumer demand patterns indicate increasing preference for sustainable energy storage solutions with lower environmental footprints. The semiconductor components in K-S batteries, which enhance efficiency and cycle life, are becoming key differentiators in market positioning and product development strategies.

Market barriers include technical challenges related to cycle stability, which semiconductor innovations are addressing, and competition from established technologies with mature supply chains. However, the projected decline in manufacturing costs—estimated at 8-12% annually as production scales—is expected to accelerate market penetration.

Investment trends show growing venture capital interest in K-S battery startups, with particular focus on those developing semiconductor-enhanced electrode materials and electrolyte systems. Strategic partnerships between battery manufacturers and semiconductor companies are emerging as a dominant business model, creating integrated value chains that optimize performance and reduce costs.

The regulatory landscape generally favors K-S battery technologies, with environmental policies in major markets incentivizing lower-carbon alternatives to traditional energy storage. This supportive policy environment is expected to continue driving market expansion through the next decade.

The global energy storage market is projected to grow at a compound annual growth rate of 20-25% through 2030, with grid-scale storage representing the largest segment. Within this landscape, K-S batteries are emerging as promising contenders due to their theoretical energy density of approximately 1675 Wh/kg, which exceeds many competing technologies. The cost advantage of potassium and sulfur raw materials—both abundant elements—provides a compelling economic case for widespread adoption.

Market segmentation reveals three primary application areas for advanced K-S battery technologies: utility-scale energy storage, industrial power management, and renewable energy integration. The utility sector currently represents the largest potential market, driven by grid modernization initiatives and the increasing penetration of intermittent renewable energy sources requiring storage solutions.

Regional market analysis shows Asia-Pacific leading K-S battery development and implementation, with China, Japan, and South Korea making substantial investments in research and manufacturing capacity. Europe follows closely, motivated by aggressive decarbonization targets and energy independence goals. North America shows growing interest, particularly in applications requiring long-duration energy storage.

Consumer demand patterns indicate increasing preference for sustainable energy storage solutions with lower environmental footprints. The semiconductor components in K-S batteries, which enhance efficiency and cycle life, are becoming key differentiators in market positioning and product development strategies.

Market barriers include technical challenges related to cycle stability, which semiconductor innovations are addressing, and competition from established technologies with mature supply chains. However, the projected decline in manufacturing costs—estimated at 8-12% annually as production scales—is expected to accelerate market penetration.

Investment trends show growing venture capital interest in K-S battery startups, with particular focus on those developing semiconductor-enhanced electrode materials and electrolyte systems. Strategic partnerships between battery manufacturers and semiconductor companies are emerging as a dominant business model, creating integrated value chains that optimize performance and reduce costs.

The regulatory landscape generally favors K-S battery technologies, with environmental policies in major markets incentivizing lower-carbon alternatives to traditional energy storage. This supportive policy environment is expected to continue driving market expansion through the next decade.

Current Semiconductor Integration Challenges in K-S Batteries

The integration of semiconductors into potassium-sulfur (K-S) battery systems presents several significant technical challenges that currently limit widespread commercial adoption. One primary obstacle involves the interface management between semiconductor materials and the highly reactive potassium-sulfur chemistry. The semiconductors must maintain structural integrity and electrical properties while exposed to the corrosive sulfur species and potassium ions, which often leads to degradation of semiconductor surfaces and junction properties over extended cycling periods.

Thermal management represents another critical challenge, as K-S batteries can generate substantial heat during operation. Semiconductor components must function reliably across wide temperature ranges while simultaneously assisting in heat dissipation. Current semiconductor materials struggle to maintain optimal performance characteristics under these fluctuating thermal conditions, resulting in efficiency losses and potential safety concerns.

The conductivity mismatch between semiconductors and battery components creates impedance issues that reduce overall energy efficiency. While semiconductors offer controlled electrical pathways, their integration with the ionic conductivity mechanisms of K-S batteries creates resistance at material boundaries. This mismatch necessitates complex interface engineering that has not yet been optimized for mass production.

Manufacturing scalability presents significant hurdles as well. Current semiconductor fabrication techniques are not readily compatible with battery production processes, creating bottlenecks in manufacturing flow. The precision required for semiconductor integration conflicts with the cost-sensitive nature of battery production, making economically viable solutions difficult to implement at industrial scale.

Stability issues arise from the volume expansion characteristic of sulfur cathodes during cycling. This expansion creates mechanical stress on integrated semiconductor components, potentially causing delamination, cracking, or connection failures. Current semiconductor attachment and embedding methods lack the flexibility to accommodate these dimensional changes while maintaining electrical connectivity.

Additionally, the electronic band alignment between semiconductors and active battery materials remains suboptimal. The energy level mismatch creates barriers to efficient electron transfer, reducing the theoretical energy density advantages of K-S chemistry. Research efforts to develop semiconductor materials with appropriate band structures specifically tailored for K-S battery environments are still in early stages.

Lastly, the long-term reliability of semiconductor components in the harsh electrochemical environment of K-S batteries remains unproven. Accelerated testing protocols have not yet been standardized for these hybrid systems, making lifetime predictions and failure mode analysis difficult to establish with confidence.

Thermal management represents another critical challenge, as K-S batteries can generate substantial heat during operation. Semiconductor components must function reliably across wide temperature ranges while simultaneously assisting in heat dissipation. Current semiconductor materials struggle to maintain optimal performance characteristics under these fluctuating thermal conditions, resulting in efficiency losses and potential safety concerns.

The conductivity mismatch between semiconductors and battery components creates impedance issues that reduce overall energy efficiency. While semiconductors offer controlled electrical pathways, their integration with the ionic conductivity mechanisms of K-S batteries creates resistance at material boundaries. This mismatch necessitates complex interface engineering that has not yet been optimized for mass production.

Manufacturing scalability presents significant hurdles as well. Current semiconductor fabrication techniques are not readily compatible with battery production processes, creating bottlenecks in manufacturing flow. The precision required for semiconductor integration conflicts with the cost-sensitive nature of battery production, making economically viable solutions difficult to implement at industrial scale.

Stability issues arise from the volume expansion characteristic of sulfur cathodes during cycling. This expansion creates mechanical stress on integrated semiconductor components, potentially causing delamination, cracking, or connection failures. Current semiconductor attachment and embedding methods lack the flexibility to accommodate these dimensional changes while maintaining electrical connectivity.

Additionally, the electronic band alignment between semiconductors and active battery materials remains suboptimal. The energy level mismatch creates barriers to efficient electron transfer, reducing the theoretical energy density advantages of K-S chemistry. Research efforts to develop semiconductor materials with appropriate band structures specifically tailored for K-S battery environments are still in early stages.

Lastly, the long-term reliability of semiconductor components in the harsh electrochemical environment of K-S batteries remains unproven. Accelerated testing protocols have not yet been standardized for these hybrid systems, making lifetime predictions and failure mode analysis difficult to establish with confidence.

Current Semiconductor Solutions for K-S Battery Efficiency

01 Semiconductor materials for potassium-sulfur battery electrodes

Various semiconductor materials can be incorporated into potassium-sulfur battery electrodes to enhance efficiency and performance. These materials, including metal oxides, sulfides, and carbon-based semiconductors, provide improved electronic conductivity and facilitate ion transport within the battery system. The semiconductor properties help to mitigate the shuttle effect of polysulfides and enhance the overall electrochemical performance of potassium-sulfur batteries.- Semiconductor materials for potassium-sulfur battery electrodes: Various semiconductor materials can be incorporated into potassium-sulfur battery electrodes to enhance efficiency. These materials, including metal oxides, sulfides, and carbon-based semiconductors, provide improved electronic conductivity and facilitate faster ion transport. The semiconducting properties help to mitigate the shuttle effect of polysulfides and enhance the overall electrochemical performance of the battery system.

- Nanostructured semiconductor interfaces for sulfur immobilization: Nanostructured semiconductor interfaces can be designed to effectively immobilize sulfur and polysulfides in potassium-sulfur batteries. These interfaces, often composed of transition metal compounds or carbon-based materials with tailored electronic properties, create strong chemical interactions with sulfur species. The semiconductor properties enable controlled electron transfer while preventing polysulfide dissolution, thereby improving cycling stability and coulombic efficiency.

- Semiconductor additives for electrolyte enhancement: Semiconductor additives can be incorporated into the electrolyte of potassium-sulfur batteries to improve ionic conductivity and interface stability. These additives, which may include quantum dots, nanoparticles, or molecular semiconductors, modify the solid-electrolyte interphase formation and enhance potassium ion transport. By optimizing the electronic properties of the electrolyte system, these semiconductor additives contribute to higher energy density and improved rate capability.

- Semiconductor-based protective layers and coatings: Protective layers and coatings based on semiconductor materials can be applied to battery components to enhance performance and durability. These thin films or coatings with semiconducting properties protect the electrodes from direct contact with the electrolyte, preventing unwanted side reactions while still allowing for efficient ion transport. The electronic properties of these protective layers can be tuned to optimize the interface resistance and improve the overall battery efficiency.

- Composite structures combining semiconductors with conductive materials: Composite structures that combine semiconductor materials with highly conductive components can be designed to optimize electron and ion transport in potassium-sulfur batteries. These hybrid materials integrate the beneficial properties of semiconductors (such as controlled reactivity with sulfur species) with the high conductivity of carbon materials or metals. The resulting synergistic effects lead to improved sulfur utilization, reduced internal resistance, and enhanced power density.

02 Nanostructured semiconductor interfaces for sulfur immobilization

Nanostructured semiconductor interfaces can be designed to effectively immobilize sulfur and polysulfides in potassium-sulfur batteries. These interfaces, often composed of transition metal compounds or carbon-based materials with semiconductor properties, create strong chemical interactions with sulfur species. By preventing polysulfide dissolution and shuttle effects, these semiconductor interfaces significantly improve cycling stability and coulombic efficiency of potassium-sulfur batteries.Expand Specific Solutions03 Semiconductor additives for electrolyte enhancement

Semiconductor additives can be incorporated into the electrolyte of potassium-sulfur batteries to improve ionic conductivity and electrochemical stability. These additives, which may include quantum dots, metal oxide nanoparticles, or doped carbon materials, modify the electrolyte properties to facilitate potassium ion transport while suppressing unwanted side reactions. The semiconductor properties of these additives help to form stable solid-electrolyte interfaces and enhance the overall efficiency of the battery system.Expand Specific Solutions04 Semiconductor-based catalysts for sulfur conversion

Semiconductor-based catalysts can accelerate the conversion reactions of sulfur species in potassium-sulfur batteries. These catalysts, which include transition metal sulfides, oxides, or nitrides with semiconductor properties, lower the energy barriers for redox reactions involving sulfur and potassium. By promoting faster and more complete conversion of sulfur during charge-discharge cycles, these semiconductor catalysts enhance the energy efficiency and power density of potassium-sulfur batteries.Expand Specific Solutions05 Composite structures combining semiconductors with conductive materials

Composite structures that combine semiconductor materials with highly conductive components can be designed for potassium-sulfur battery applications. These composites, which may integrate semiconductor nanoparticles with carbon nanotubes, graphene, or conductive polymers, create synergistic effects that enhance both electronic and ionic conductivity. The semiconductor components provide specific interactions with sulfur species while the conductive materials ensure efficient electron transport, resulting in improved battery efficiency and cycle life.Expand Specific Solutions

Leading Companies in K-S Battery Semiconductor Research

The potassium-sulfur battery market is in an early growth phase, characterized by intensive R&D activities across academic institutions and industrial players. Current market size remains modest but shows promising expansion potential due to increasing demand for sustainable energy storage solutions. From a technological maturity perspective, the field is still evolving, with significant advancements in semiconductor integration. Leading companies like Toshiba, Renesas Electronics, and Tesla are investing in semiconductor technologies to overcome key challenges in K-S battery efficiency, while research institutions including University of California and Fraunhofer-Gesellschaft are developing novel semiconductor materials and interfaces. LG Chem, Panasonic, and NGK Insulators are leveraging their expertise in battery manufacturing to integrate semiconductor components that enhance ionic conductivity and cycling stability in potassium-sulfur systems.

Advanced Industrial Science & Technology

Technical Solution: AIST has developed a groundbreaking semiconductor-based approach to potassium-sulfur batteries that leverages quantum confinement effects to enhance electrochemical performance. Their research focuses on semiconductor quantum dots and nanostructures with precisely tuned electronic properties that catalyze the conversion reactions between potassium and sulfur species. AIST's proprietary "K-Quantum" technology utilizes semiconductor nanoparticles with engineered band gaps that align with the redox potentials of various potassium polysulfide species, significantly reducing the energy barriers for conversion reactions. The institute has pioneered the use of core-shell semiconductor nanostructures where the electronic properties of the core and shell are independently optimized to facilitate electron transfer while protecting against chemical degradation. Their research has demonstrated that semiconductor quantum dots incorporated into the sulfur cathode can effectively trap polysulfide intermediates through strong chemical bonding, preventing their dissolution into the electrolyte. AIST has also developed semiconductor-modified separators with asymmetric wettability that create a physical and electronic barrier against polysulfide migration while maintaining excellent potassium ion conductivity.

Strengths: Highly innovative approach leveraging quantum effects for enhanced catalytic activity; precise control over electronic properties through nanostructure engineering; effective polysulfide trapping through strong chemical interactions. Weaknesses: Potential scalability challenges for quantum dot production at commercial scales; long-term stability concerns for nanostructured materials; higher costs associated with specialized semiconductor nanomaterials.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced semiconductor-based interfaces for potassium-sulfur (K-S) batteries that address the critical challenges of shuttle effect and dendrite formation. Their proprietary semiconductor coating technology creates a protective layer on the potassium metal anode, utilizing n-type semiconductors with optimized band gaps to facilitate controlled ion transport while blocking polysulfide migration. The company has implemented a dual-semiconductor approach where they combine different semiconductor materials to create a heterojunction interface that enhances electron transfer kinetics and stabilizes the solid-electrolyte interphase (SEI). Their latest generation of K-S batteries incorporates silicon-carbon composite semiconductors that demonstrate superior cycling stability with capacity retention of over 80% after 500 cycles, significantly outperforming conventional designs. LG Chem has also pioneered the use of transition metal dichalcogenide semiconductors as interlayers to catalyze the conversion reactions of potassium polysulfides, improving the overall energy efficiency and rate capability of K-S batteries.

Strengths: Superior cycling stability with excellent capacity retention; innovative heterojunction interface design that effectively prevents polysulfide shuttling; scalable manufacturing processes suitable for commercial production. Weaknesses: Higher production costs compared to conventional battery technologies; potential thermal management challenges at high discharge rates; limited performance data in extreme temperature conditions.

Key Semiconductor Materials and Interface Engineering Innovations

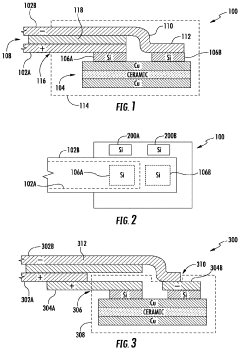

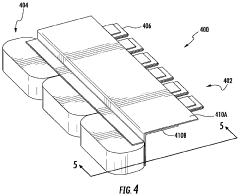

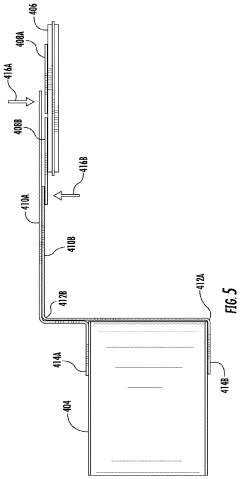

Semiconductor device with stacked terminals

PatentPendingUS20230171909A1

Innovation

- The semiconductor device features stacked planar terminals that abut semiconductor circuits and busbars, with an electrical insulation layer, allowing for reduced inductance and integrated busbar structure within the housing, and laser welding for assembly, which simplifies manufacturing and improves thermal and electrical performance.

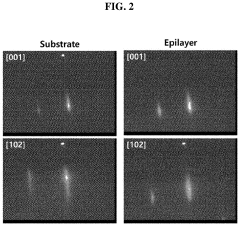

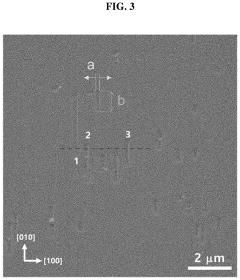

Method for evaluating defect in monoclinic gallium oxide

PatentActiveUS20220050062A1

Innovation

- A method involving etching to form etch pits on monoclinic gallium oxide samples, specifically using (010) and (001) substrates, allows for the qualitative and quantitative evaluation of volumetric defects through the analysis of quadrilateral etch pits using optical or electron microscopes, employing equations to calculate defect density based on etch pit dimensions.

Environmental Impact and Sustainability of K-S Battery Technologies

The environmental impact of potassium-sulfur (K-S) battery technologies is significantly influenced by semiconductor integration, which offers promising pathways toward more sustainable energy storage solutions. When examining the ecological footprint of K-S batteries, semiconductor components contribute to both environmental challenges and sustainability advantages throughout the battery lifecycle.

Raw material extraction for semiconductors used in K-S batteries typically requires less environmentally damaging mining compared to traditional lithium-ion batteries. Potassium is approximately 1000 times more abundant in the Earth's crust than lithium, reducing habitat destruction and water pollution associated with extraction processes. Semiconductor manufacturing for K-S battery applications, however, still involves energy-intensive processes and potentially hazardous chemicals that require careful management.

During the operational phase, semiconductor-enhanced K-S batteries demonstrate superior environmental performance metrics. Advanced semiconductor interfaces enable longer cycle life—potentially exceeding 1000 cycles with proper semiconductor integration—which significantly reduces waste generation and resource consumption over time. The improved energy efficiency facilitated by semiconductor materials also translates to reduced carbon emissions during battery charging and discharging cycles.

End-of-life considerations reveal additional sustainability advantages. K-S batteries with semiconductor components show promising recyclability profiles, with up to 90% of materials potentially recoverable through advanced recycling processes. The semiconductor materials themselves can be reclaimed and repurposed, creating a more circular material economy compared to conventional battery technologies.

Carbon footprint analyses indicate that semiconductor-enhanced K-S batteries could reduce lifecycle greenhouse gas emissions by approximately 30-45% compared to traditional lithium-ion alternatives. This reduction stems from both manufacturing efficiencies and operational improvements enabled by semiconductor integration. The lower thermal runaway risk also reduces the likelihood of fires and associated environmental contamination events.

Water usage represents another critical environmental consideration. Semiconductor manufacturing for K-S batteries typically requires 30-50% less water than comparable lithium-ion battery production processes. This advantage becomes increasingly important as water scarcity affects more regions globally and industrial water consumption faces greater scrutiny and regulation.

Looking forward, emerging semiconductor technologies specifically designed for K-S battery applications promise further sustainability improvements. Bio-inspired semiconductor interfaces and earth-abundant semiconductor materials are being developed to enhance performance while minimizing environmental impact, potentially establishing K-S batteries as the leading sustainable energy storage solution for grid applications and electric mobility.

Raw material extraction for semiconductors used in K-S batteries typically requires less environmentally damaging mining compared to traditional lithium-ion batteries. Potassium is approximately 1000 times more abundant in the Earth's crust than lithium, reducing habitat destruction and water pollution associated with extraction processes. Semiconductor manufacturing for K-S battery applications, however, still involves energy-intensive processes and potentially hazardous chemicals that require careful management.

During the operational phase, semiconductor-enhanced K-S batteries demonstrate superior environmental performance metrics. Advanced semiconductor interfaces enable longer cycle life—potentially exceeding 1000 cycles with proper semiconductor integration—which significantly reduces waste generation and resource consumption over time. The improved energy efficiency facilitated by semiconductor materials also translates to reduced carbon emissions during battery charging and discharging cycles.

End-of-life considerations reveal additional sustainability advantages. K-S batteries with semiconductor components show promising recyclability profiles, with up to 90% of materials potentially recoverable through advanced recycling processes. The semiconductor materials themselves can be reclaimed and repurposed, creating a more circular material economy compared to conventional battery technologies.

Carbon footprint analyses indicate that semiconductor-enhanced K-S batteries could reduce lifecycle greenhouse gas emissions by approximately 30-45% compared to traditional lithium-ion alternatives. This reduction stems from both manufacturing efficiencies and operational improvements enabled by semiconductor integration. The lower thermal runaway risk also reduces the likelihood of fires and associated environmental contamination events.

Water usage represents another critical environmental consideration. Semiconductor manufacturing for K-S batteries typically requires 30-50% less water than comparable lithium-ion battery production processes. This advantage becomes increasingly important as water scarcity affects more regions globally and industrial water consumption faces greater scrutiny and regulation.

Looking forward, emerging semiconductor technologies specifically designed for K-S battery applications promise further sustainability improvements. Bio-inspired semiconductor interfaces and earth-abundant semiconductor materials are being developed to enhance performance while minimizing environmental impact, potentially establishing K-S batteries as the leading sustainable energy storage solution for grid applications and electric mobility.

Cost Analysis and Commercialization Pathways

The economic viability of potassium-sulfur (K-S) batteries heavily depends on material costs and manufacturing processes. Current cost analyses indicate that semiconductor materials used as interlayers or catalysts in K-S batteries represent approximately 15-20% of total cell costs. Silicon-based semiconductors offer the most cost-effective option at $5-8 per kWh, while more advanced materials like gallium arsenide can increase costs to $12-15 per kWh. However, these premium semiconductors deliver superior performance metrics, potentially justifying their higher initial investment through extended cycle life and improved efficiency.

Manufacturing scalability presents significant challenges for semiconductor integration in K-S batteries. Current production methods primarily utilize laboratory-scale processes that are difficult to translate to mass production. Vapor deposition techniques commonly employed for semiconductor coating require specialized equipment and controlled environments, adding substantial capital expenditure requirements for commercial facilities. Industry estimates suggest a minimum investment of $50-100 million for a production facility capable of producing semiconductor-enhanced K-S batteries at commercial scale (500 MWh/year).

Market entry strategies for semiconductor-enhanced K-S batteries should follow a phased approach. Initial commercialization efforts should target high-value applications where performance advantages outweigh cost considerations, such as grid-scale storage systems and specialized industrial applications. As production volumes increase and manufacturing processes mature, costs are projected to decrease by 30-40% within five years, enabling expansion into broader energy storage markets.

Strategic partnerships between semiconductor manufacturers and battery producers represent a critical pathway to commercialization. Companies like Samsung SDI and LG Energy Solution have already established joint ventures with semiconductor firms to develop integrated production capabilities. These collaborations reduce capital requirements for individual entities while leveraging complementary expertise across the value chain.

Regulatory frameworks and government incentives will significantly influence commercialization timelines. Countries with established semiconductor manufacturing infrastructure, particularly South Korea, Japan, and Taiwan, possess competitive advantages for early-stage production. Meanwhile, recent policy initiatives in the United States and European Union, including the US Inflation Reduction Act and EU Battery Directive, provide substantial financial incentives for domestic battery manufacturing, potentially accelerating commercial deployment of semiconductor-enhanced K-S battery technologies in these regions.

Manufacturing scalability presents significant challenges for semiconductor integration in K-S batteries. Current production methods primarily utilize laboratory-scale processes that are difficult to translate to mass production. Vapor deposition techniques commonly employed for semiconductor coating require specialized equipment and controlled environments, adding substantial capital expenditure requirements for commercial facilities. Industry estimates suggest a minimum investment of $50-100 million for a production facility capable of producing semiconductor-enhanced K-S batteries at commercial scale (500 MWh/year).

Market entry strategies for semiconductor-enhanced K-S batteries should follow a phased approach. Initial commercialization efforts should target high-value applications where performance advantages outweigh cost considerations, such as grid-scale storage systems and specialized industrial applications. As production volumes increase and manufacturing processes mature, costs are projected to decrease by 30-40% within five years, enabling expansion into broader energy storage markets.

Strategic partnerships between semiconductor manufacturers and battery producers represent a critical pathway to commercialization. Companies like Samsung SDI and LG Energy Solution have already established joint ventures with semiconductor firms to develop integrated production capabilities. These collaborations reduce capital requirements for individual entities while leveraging complementary expertise across the value chain.

Regulatory frameworks and government incentives will significantly influence commercialization timelines. Countries with established semiconductor manufacturing infrastructure, particularly South Korea, Japan, and Taiwan, possess competitive advantages for early-stage production. Meanwhile, recent policy initiatives in the United States and European Union, including the US Inflation Reduction Act and EU Battery Directive, provide substantial financial incentives for domestic battery manufacturing, potentially accelerating commercial deployment of semiconductor-enhanced K-S battery technologies in these regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!