Structural Optimizations in Potassium-Sulfur Battery Systems

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K-S Battery Development Background and Objectives

Potassium-sulfur (K-S) battery systems have emerged as a promising alternative to lithium-ion batteries due to their potential for higher energy density, lower cost, and environmental sustainability. The development of K-S batteries traces back to the early 2010s when researchers began exploring potassium as an alternative to lithium in energy storage applications. Potassium is approximately 1,000 times more abundant in the Earth's crust than lithium, making it significantly more cost-effective and accessible for large-scale energy storage solutions.

The evolution of K-S battery technology has been marked by several key advancements in electrode materials, electrolyte formulations, and cell architectures. Initially, K-S batteries faced substantial challenges including rapid capacity fading, poor cycle life, and safety concerns related to the shuttle effect of polysulfides. These limitations hindered their practical application despite their theoretical energy density of approximately 1,023 Wh/kg, which exceeds that of many commercial battery systems.

Recent technological breakthroughs have focused on structural optimizations to address these fundamental challenges. Researchers have developed novel carbon-sulfur composite cathodes, advanced separator designs, and innovative electrolyte systems to mitigate polysulfide dissolution and shuttle effects. The introduction of hierarchical porous carbon structures and functional additives has significantly improved the electrochemical performance and stability of K-S batteries.

The primary technical objectives in K-S battery development include achieving high sulfur utilization, enhancing cycle stability beyond 500 cycles, improving rate capability for fast charging applications, and developing scalable manufacturing processes. Researchers aim to increase the practical energy density to at least 400-500 Wh/kg while maintaining stable performance at room temperature, which would represent a significant advancement over current lithium-ion technologies.

Global research efforts are increasingly focused on structural optimizations at multiple scales—from atomic-level modifications of electrode materials to macro-scale cell design improvements. These optimizations aim to create more efficient ion transport pathways, enhance electronic conductivity, and establish robust interfaces between battery components. Advanced characterization techniques such as in-situ X-ray diffraction and cryo-electron microscopy have been instrumental in understanding the complex reaction mechanisms and degradation processes in K-S systems.

The trajectory of K-S battery development aligns with broader industry trends toward sustainable, high-performance energy storage solutions. As renewable energy integration accelerates and electric vehicle adoption expands, the demand for cost-effective, high-energy-density batteries continues to grow. K-S technology represents a promising pathway to meet these evolving market needs while reducing dependence on critical materials like lithium and cobalt.

The evolution of K-S battery technology has been marked by several key advancements in electrode materials, electrolyte formulations, and cell architectures. Initially, K-S batteries faced substantial challenges including rapid capacity fading, poor cycle life, and safety concerns related to the shuttle effect of polysulfides. These limitations hindered their practical application despite their theoretical energy density of approximately 1,023 Wh/kg, which exceeds that of many commercial battery systems.

Recent technological breakthroughs have focused on structural optimizations to address these fundamental challenges. Researchers have developed novel carbon-sulfur composite cathodes, advanced separator designs, and innovative electrolyte systems to mitigate polysulfide dissolution and shuttle effects. The introduction of hierarchical porous carbon structures and functional additives has significantly improved the electrochemical performance and stability of K-S batteries.

The primary technical objectives in K-S battery development include achieving high sulfur utilization, enhancing cycle stability beyond 500 cycles, improving rate capability for fast charging applications, and developing scalable manufacturing processes. Researchers aim to increase the practical energy density to at least 400-500 Wh/kg while maintaining stable performance at room temperature, which would represent a significant advancement over current lithium-ion technologies.

Global research efforts are increasingly focused on structural optimizations at multiple scales—from atomic-level modifications of electrode materials to macro-scale cell design improvements. These optimizations aim to create more efficient ion transport pathways, enhance electronic conductivity, and establish robust interfaces between battery components. Advanced characterization techniques such as in-situ X-ray diffraction and cryo-electron microscopy have been instrumental in understanding the complex reaction mechanisms and degradation processes in K-S systems.

The trajectory of K-S battery development aligns with broader industry trends toward sustainable, high-performance energy storage solutions. As renewable energy integration accelerates and electric vehicle adoption expands, the demand for cost-effective, high-energy-density batteries continues to grow. K-S technology represents a promising pathway to meet these evolving market needs while reducing dependence on critical materials like lithium and cobalt.

Market Analysis for Next-Generation Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the push for electrification across various sectors. Current projections indicate the energy storage market will reach $546 billion by 2035, with a compound annual growth rate of approximately 20% between 2023 and 2035. Within this expanding landscape, potassium-sulfur (K-S) battery systems are emerging as a promising alternative to traditional lithium-ion technologies.

Market demand for K-S battery systems is primarily fueled by three key factors: cost advantages, resource abundance, and performance potential. Potassium is approximately 1000 times more abundant in the Earth's crust than lithium, offering significant raw material cost reductions. Current market analysis suggests that K-S batteries could potentially achieve production costs 30-40% lower than conventional lithium-ion batteries at scale.

The industrial energy storage sector represents the largest immediate market opportunity for K-S battery systems, with grid-scale applications projected to grow at 25% annually through 2030. This segment values the theoretical high energy density of K-S systems (up to 1800 Wh/kg) and their potential for long-duration storage applications. However, commercial adoption remains limited due to structural optimization challenges that currently restrict practical energy densities to 30-40% of theoretical values.

Consumer electronics and electric vehicle manufacturers are showing increasing interest in K-S technology, particularly as concerns about lithium supply chain vulnerabilities grow. Market research indicates that 68% of battery manufacturers are actively exploring potassium-based chemistries as part of their technology diversification strategies. This represents a significant shift from just 23% in 2020.

Regional market analysis reveals Asia-Pacific as the dominant manufacturing hub, with China leading research investments in alternative battery technologies including K-S systems. Europe follows with strong policy support for sustainable battery technologies, while North America shows increasing venture capital activity in this space, with investments in K-S startups growing by 85% in the past two years.

Market barriers include competition from other emerging battery technologies such as sodium-ion and solid-state batteries, which are at more advanced commercialization stages. Additionally, the current market perception of K-S technology is influenced by technical challenges related to structural stability during cycling, which directly impacts commercial viability and market acceptance.

Market demand for K-S battery systems is primarily fueled by three key factors: cost advantages, resource abundance, and performance potential. Potassium is approximately 1000 times more abundant in the Earth's crust than lithium, offering significant raw material cost reductions. Current market analysis suggests that K-S batteries could potentially achieve production costs 30-40% lower than conventional lithium-ion batteries at scale.

The industrial energy storage sector represents the largest immediate market opportunity for K-S battery systems, with grid-scale applications projected to grow at 25% annually through 2030. This segment values the theoretical high energy density of K-S systems (up to 1800 Wh/kg) and their potential for long-duration storage applications. However, commercial adoption remains limited due to structural optimization challenges that currently restrict practical energy densities to 30-40% of theoretical values.

Consumer electronics and electric vehicle manufacturers are showing increasing interest in K-S technology, particularly as concerns about lithium supply chain vulnerabilities grow. Market research indicates that 68% of battery manufacturers are actively exploring potassium-based chemistries as part of their technology diversification strategies. This represents a significant shift from just 23% in 2020.

Regional market analysis reveals Asia-Pacific as the dominant manufacturing hub, with China leading research investments in alternative battery technologies including K-S systems. Europe follows with strong policy support for sustainable battery technologies, while North America shows increasing venture capital activity in this space, with investments in K-S startups growing by 85% in the past two years.

Market barriers include competition from other emerging battery technologies such as sodium-ion and solid-state batteries, which are at more advanced commercialization stages. Additionally, the current market perception of K-S technology is influenced by technical challenges related to structural stability during cycling, which directly impacts commercial viability and market acceptance.

Technical Challenges in K-S Battery Systems

Potassium-sulfur (K-S) battery systems face significant technical challenges that currently limit their widespread commercial adoption. The primary obstacle lies in the shuttle effect, where soluble polysulfide intermediates migrate between electrodes during cycling, causing capacity fading and reduced battery lifespan. This phenomenon is particularly pronounced in K-S systems due to potassium's higher reactivity compared to lithium, creating more aggressive side reactions with the electrolyte and sulfur cathode.

Another critical challenge is the substantial volume expansion during cycling. Sulfur undergoes approximately 80% volume change when converting to K2S, creating mechanical stress that leads to electrode pulverization and loss of electrical contact. This expansion is more problematic in K-S systems than in Li-S counterparts due to the larger ionic radius of potassium, which exacerbates structural instability.

The poor electronic conductivity of sulfur (5×10^-30 S/cm) presents another significant hurdle. This inherent property necessitates the incorporation of conductive additives, which reduces the overall energy density of the battery system. Additionally, the larger size of potassium ions compared to lithium ions results in slower diffusion kinetics, further limiting rate capability and power performance.

Electrolyte stability remains a persistent challenge in K-S batteries. Potassium metal anodes are highly reactive with conventional electrolytes, forming unstable solid electrolyte interphase (SEI) layers that continuously consume electrolyte and active materials. This reactivity is more severe than in lithium-based systems, requiring specialized electrolyte formulations that can withstand potassium's aggressive chemical nature.

The formation of insulating discharge products, primarily K2S, creates additional complications. These products have poor ionic and electronic conductivity, leading to incomplete utilization of active materials and capacity limitations. The larger size of potassium ions also results in slower conversion reactions compared to lithium systems.

From a practical perspective, K-S batteries face challenges in achieving adequate cycle life. Current research prototypes typically demonstrate rapid capacity decay after 100-200 cycles, falling short of the 1,000+ cycles required for commercial viability. The self-discharge rate is also problematic, with K-S batteries losing significant capacity during storage due to ongoing chemical reactions between the electrodes and electrolyte.

Finally, safety concerns persist due to potassium's higher reactivity with moisture and air compared to lithium. This necessitates more robust encapsulation technologies and safety mechanisms, adding complexity and cost to battery design and manufacturing processes.

Another critical challenge is the substantial volume expansion during cycling. Sulfur undergoes approximately 80% volume change when converting to K2S, creating mechanical stress that leads to electrode pulverization and loss of electrical contact. This expansion is more problematic in K-S systems than in Li-S counterparts due to the larger ionic radius of potassium, which exacerbates structural instability.

The poor electronic conductivity of sulfur (5×10^-30 S/cm) presents another significant hurdle. This inherent property necessitates the incorporation of conductive additives, which reduces the overall energy density of the battery system. Additionally, the larger size of potassium ions compared to lithium ions results in slower diffusion kinetics, further limiting rate capability and power performance.

Electrolyte stability remains a persistent challenge in K-S batteries. Potassium metal anodes are highly reactive with conventional electrolytes, forming unstable solid electrolyte interphase (SEI) layers that continuously consume electrolyte and active materials. This reactivity is more severe than in lithium-based systems, requiring specialized electrolyte formulations that can withstand potassium's aggressive chemical nature.

The formation of insulating discharge products, primarily K2S, creates additional complications. These products have poor ionic and electronic conductivity, leading to incomplete utilization of active materials and capacity limitations. The larger size of potassium ions also results in slower conversion reactions compared to lithium systems.

From a practical perspective, K-S batteries face challenges in achieving adequate cycle life. Current research prototypes typically demonstrate rapid capacity decay after 100-200 cycles, falling short of the 1,000+ cycles required for commercial viability. The self-discharge rate is also problematic, with K-S batteries losing significant capacity during storage due to ongoing chemical reactions between the electrodes and electrolyte.

Finally, safety concerns persist due to potassium's higher reactivity with moisture and air compared to lithium. This necessitates more robust encapsulation technologies and safety mechanisms, adding complexity and cost to battery design and manufacturing processes.

Current Structural Design Solutions

01 Electrode structure and composition for potassium-sulfur batteries

The electrode structure and composition play a crucial role in potassium-sulfur battery systems. Various materials such as carbon-based substrates, conductive polymers, and metal oxides can be used to create electrodes that effectively host sulfur and facilitate potassium ion transport. These structures often incorporate porous designs to accommodate volume changes during cycling and provide sufficient contact between electrolyte and active materials, thereby enhancing the overall performance and stability of the battery system.- Electrode structure and composition for potassium-sulfur batteries: The electrode structure and composition play a crucial role in potassium-sulfur battery performance. Various materials such as carbon-based substrates, conductive polymers, and metal oxides are used to create electrodes that can effectively host sulfur and facilitate potassium ion transport. These structures are designed to improve the electrical conductivity, accommodate volume changes during cycling, and enhance the overall electrochemical performance of the battery system.

- Electrolyte systems for potassium-sulfur batteries: Specialized electrolyte formulations are essential for potassium-sulfur battery systems to address challenges such as the shuttle effect and electrode degradation. These electrolytes typically contain potassium salts dissolved in organic solvents, sometimes with additives to improve ionic conductivity and interface stability. Some advanced electrolyte systems incorporate ionic liquids, solid-state electrolytes, or polymer-based electrolytes to enhance safety and electrochemical stability during battery operation.

- Separator designs and materials for potassium-sulfur batteries: Separators in potassium-sulfur batteries serve to prevent short circuits while allowing efficient ion transport between electrodes. Advanced separator designs incorporate functional coatings or modified structures to mitigate the polysulfide shuttle effect. Materials such as modified polymers, ceramic-polymer composites, and functionalized membranes are used to enhance the mechanical strength, thermal stability, and ion selectivity of separators, thereby improving the cycle life and safety of potassium-sulfur battery systems.

- Cell architecture and assembly methods: The overall cell architecture and assembly methods significantly impact the performance and durability of potassium-sulfur batteries. Various cell configurations, including coin cells, pouch cells, and cylindrical cells, are designed with specific structural features to optimize space utilization and thermal management. Advanced assembly techniques focus on controlling the pressure distribution, minimizing dead space, and ensuring proper sealing to prevent electrolyte leakage and moisture ingress, which are critical for long-term stability.

- Encapsulation and protection strategies for sulfur cathodes: Encapsulation and protection strategies for sulfur cathodes are developed to address the volume expansion and polysulfide dissolution issues in potassium-sulfur batteries. These approaches include core-shell structures, yolk-shell designs, and hierarchical porous frameworks that physically confine sulfur while allowing ion transport. Chemical modification techniques, such as surface functionalization and protective coatings, are also employed to enhance the chemical interaction between sulfur and the host material, improving cycling stability and capacity retention.

02 Electrolyte systems for potassium-sulfur batteries

Specialized electrolyte formulations are essential for potassium-sulfur battery systems to address challenges such as the shuttle effect and electrode degradation. These electrolytes typically contain potassium salts dissolved in organic solvents, sometimes with additives that form protective interfaces on electrode surfaces. Innovations in electrolyte design focus on improving ionic conductivity, electrochemical stability, and compatibility with both the potassium anode and sulfur cathode to enhance cycle life and energy density of the battery system.Expand Specific Solutions03 Separator technologies for potassium-sulfur batteries

Advanced separator technologies are critical components in potassium-sulfur battery systems, serving to prevent short circuits while allowing efficient ion transport. These separators often incorporate functional coatings or modified structures that can selectively block polysulfide migration while maintaining high potassium ion conductivity. Materials such as modified polymers, ceramic-polymer composites, and functionalized membranes are employed to enhance the electrochemical performance and safety of potassium-sulfur batteries.Expand Specific Solutions04 Cell assembly and packaging for potassium-sulfur batteries

The structural design of cell assembly and packaging significantly impacts the performance and safety of potassium-sulfur battery systems. Innovations in this area include specialized housing materials resistant to potassium corrosion, pressure management systems to accommodate volume changes, and thermal management solutions. Various cell configurations such as pouch, prismatic, and coin cells are adapted specifically for potassium-sulfur chemistry to optimize energy density, mechanical stability, and manufacturing feasibility.Expand Specific Solutions05 Protective interfaces and interlayers for potassium-sulfur batteries

Protective interfaces and interlayers are engineered to address the reactivity between potassium metal anodes and sulfur cathodes in battery systems. These specialized layers can be applied to electrode surfaces or incorporated within the cell structure to mitigate side reactions, prevent dendrite formation, and contain polysulfide dissolution. Materials such as artificial solid electrolyte interphases, functional polymers, and inorganic protective films are designed to enhance the cycling stability and safety of potassium-sulfur batteries while maintaining high energy density.Expand Specific Solutions

Leading Organizations in K-S Battery Research

The potassium-sulfur battery technology market is currently in an early growth phase, characterized by intensive research and development activities rather than widespread commercialization. The global market size remains relatively modest compared to established battery technologies, but is projected to expand significantly due to potassium's abundance and cost advantages over lithium. From a technical maturity perspective, structural optimization challenges remain substantial, with key players pursuing different approaches. Major corporations like LG Energy Solution, Samsung Electronics, and SK ON are investing in K-S battery research to diversify their energy storage portfolios. Academic institutions including Northwestern University and Chinese Academy of Sciences are advancing fundamental research, while specialized companies like Gelion Technologies are developing proprietary gel-based electrolyte solutions to address the polysulfide shuttle effect and structural stability issues that currently limit commercial viability.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced structural optimization techniques for potassium-sulfur (K-S) battery systems, focusing on novel carbon-sulfur composite cathode architectures. Their approach involves embedding sulfur within hierarchical porous carbon frameworks to mitigate the shuttle effect and volume expansion issues. The company has pioneered a dual-confinement strategy where sulfur is first encapsulated in microporous carbon and then further protected by a mesoporous carbon shell, creating a "prison within prison" structure. This design effectively traps polysulfide intermediates while allowing efficient potassium ion transport. Additionally, LG has implemented specialized electrolyte formulations containing fluoroethylene carbonate (FEC) additives that form stable solid electrolyte interphase (SEI) layers on potassium metal anodes, significantly improving cycling stability. Their latest generation K-S batteries incorporate nitrogen and oxygen co-doped carbon hosts that provide chemical anchoring sites for polysulfides, further enhancing capacity retention.

Strengths: Superior polysulfide confinement through hierarchical carbon structures; excellent cycling stability due to proprietary electrolyte formulations; high energy density potential exceeding 400 Wh/kg. Weaknesses: Higher manufacturing complexity compared to conventional lithium-ion batteries; challenges with scale-up of specialized carbon materials; relatively higher cost of production due to complex structural engineering requirements.

Gelion Technologies Pty Ltd.

Technical Solution: Gelion Technologies has pioneered a revolutionary approach to potassium-sulfur battery systems through their proprietary gel-based electrolyte technology. Their structural optimization focuses on a non-flammable inorganic gel electrolyte matrix that simultaneously serves as both an ion conductor and a physical barrier to polysulfide shuttling. The company's "Endure" platform specifically designed for K-S chemistry incorporates zinc-tin oxide nanoparticles dispersed throughout a silica-based gel framework, creating nanoscale chambers that physically constrain sulfur and its discharge products. This three-dimensional network provides mechanical stability while maintaining high ionic conductivity (>10^-3 S/cm at room temperature). Gelion has further enhanced their system by incorporating potassium-ion selective channels within the gel structure, allowing preferential transport of K+ ions while blocking larger polysulfide anions. Their latest innovation includes a gradient-density gel structure that accommodates volume changes during cycling, with a more rigid outer layer and increasingly flexible inner layers surrounding the active materials. This structural design has demonstrated over 500 stable cycles with capacity retention above 80% in prototype cells.

Strengths: Exceptional safety profile due to non-flammable gel electrolyte; superior polysulfide containment through physical confinement; good thermal stability across wide temperature range (-20°C to 60°C). Weaknesses: Lower power density compared to liquid electrolyte systems; more complex manufacturing process requiring precise control of gel polymerization; potential challenges with internal resistance at high discharge rates.

Key Patents and Innovations in K-S Architecture

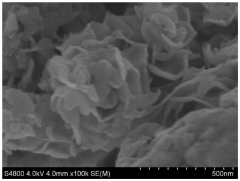

Preparation method and application of rose-shaped composite electrode material for potassium-sulfur battery

PatentPendingCN118016833A

Innovation

- The Fe@MoS2 composite structure was synthesized using a microwave-assisted solvothermal method. The rose-like Fe/Pd@MoS2 composite material was prepared by rotating packed bed and freeze-drying methods. It was combined with laser induction and heat treatment to form Fe/Pd@ with high conductivity and catalytic activity. MoS2/S composite cathode material inhibits the shuttle effect and accumulation of polysulfides.

Electrode unit

PatentWO2013186204A1

Innovation

- An electrode unit design featuring a solid electrolyte separating molten cathode and anode materials with a porous electrode connected via a non-electron-conducting intermediate layer, using a flat tube or sheet metal wall with structured inlet and outlet openings to ensure uniform material flow and prevent reaction product re-entry, and employing stainless steel displacers for enhanced mechanical strength and corrosion resistance.

Material Science Advancements for K-S Systems

Recent advancements in material science have significantly propelled the development of potassium-sulfur (K-S) battery systems. The exploration of novel materials with enhanced structural properties has been pivotal in addressing the inherent challenges of K-S batteries, particularly the shuttle effect and volume expansion during cycling.

Nanostructured carbon materials have emerged as promising hosts for sulfur cathodes in K-S systems. Carbon nanotubes, graphene, and mesoporous carbon frameworks provide excellent electrical conductivity while offering structural stability to accommodate sulfur's volumetric changes. These materials create a conductive network that facilitates electron transfer and physically constrains polysulfide intermediates, mitigating their dissolution into the electrolyte.

Metal-organic frameworks (MOFs) represent another breakthrough in K-S battery material science. Their highly ordered crystalline structures with tunable pore sizes and functionalities enable precise control over sulfur confinement and potassium ion transport. MOFs modified with polar functional groups have demonstrated enhanced affinity for polysulfides, significantly improving cycling stability and coulombic efficiency.

Polymer-based composites have also gained attention for their flexibility and adaptability in K-S systems. Conductive polymers like polyaniline and polypyrrole not only improve the overall conductivity but also form chemical bonds with polysulfides, effectively trapping them within the cathode structure. These materials can be engineered to create hierarchical architectures that optimize ion diffusion pathways while maintaining structural integrity.

Advanced characterization techniques have been instrumental in understanding the material-level interactions in K-S batteries. In-situ X-ray diffraction, transmission electron microscopy, and synchrotron-based spectroscopy have revealed critical insights into the structural evolution of electrode materials during cycling, guiding rational design approaches for next-generation materials.

Computational materials science has accelerated the discovery and optimization of K-S battery materials. Density functional theory calculations and molecular dynamics simulations have elucidated the fundamental mechanisms of potassium-sulfur interactions at the atomic level, enabling the prediction of novel material compositions with enhanced performance characteristics before experimental validation.

The integration of two-dimensional materials like MXenes and transition metal dichalcogenides represents the cutting edge of material science for K-S batteries. These materials offer exceptional surface-to-volume ratios and unique electronic properties that can be leveraged to create highly efficient sulfur hosts with minimal weight penalties, addressing the energy density limitations of current systems.

Nanostructured carbon materials have emerged as promising hosts for sulfur cathodes in K-S systems. Carbon nanotubes, graphene, and mesoporous carbon frameworks provide excellent electrical conductivity while offering structural stability to accommodate sulfur's volumetric changes. These materials create a conductive network that facilitates electron transfer and physically constrains polysulfide intermediates, mitigating their dissolution into the electrolyte.

Metal-organic frameworks (MOFs) represent another breakthrough in K-S battery material science. Their highly ordered crystalline structures with tunable pore sizes and functionalities enable precise control over sulfur confinement and potassium ion transport. MOFs modified with polar functional groups have demonstrated enhanced affinity for polysulfides, significantly improving cycling stability and coulombic efficiency.

Polymer-based composites have also gained attention for their flexibility and adaptability in K-S systems. Conductive polymers like polyaniline and polypyrrole not only improve the overall conductivity but also form chemical bonds with polysulfides, effectively trapping them within the cathode structure. These materials can be engineered to create hierarchical architectures that optimize ion diffusion pathways while maintaining structural integrity.

Advanced characterization techniques have been instrumental in understanding the material-level interactions in K-S batteries. In-situ X-ray diffraction, transmission electron microscopy, and synchrotron-based spectroscopy have revealed critical insights into the structural evolution of electrode materials during cycling, guiding rational design approaches for next-generation materials.

Computational materials science has accelerated the discovery and optimization of K-S battery materials. Density functional theory calculations and molecular dynamics simulations have elucidated the fundamental mechanisms of potassium-sulfur interactions at the atomic level, enabling the prediction of novel material compositions with enhanced performance characteristics before experimental validation.

The integration of two-dimensional materials like MXenes and transition metal dichalcogenides represents the cutting edge of material science for K-S batteries. These materials offer exceptional surface-to-volume ratios and unique electronic properties that can be leveraged to create highly efficient sulfur hosts with minimal weight penalties, addressing the energy density limitations of current systems.

Environmental Impact and Sustainability Assessment

The environmental impact of potassium-sulfur (K-S) battery systems represents a critical dimension in evaluating their viability as next-generation energy storage solutions. Unlike lithium-ion batteries, K-S systems utilize potassium, which is approximately 1000 times more abundant in the Earth's crust than lithium, significantly reducing resource depletion concerns and extraction-related environmental damage. This abundance translates to lower mining intensity and reduced habitat disruption in comparison to conventional battery technologies.

Structural optimizations in K-S batteries directly influence their environmental footprint throughout the entire lifecycle. Carbon-based frameworks and hierarchical porous structures not only enhance electrochemical performance but also enable the use of more environmentally benign materials. Recent research indicates that optimized sulfur hosts with rational pore structures can achieve sulfur utilization rates exceeding 80%, substantially reducing material waste during manufacturing processes.

The production phase of structurally optimized K-S batteries demonstrates promising sustainability metrics. Life cycle assessments reveal that carbon-sulfur composite cathodes with engineered interfaces can reduce energy consumption during manufacturing by approximately 30% compared to conventional cathode production methods. Additionally, the elimination of cobalt and nickel from the battery composition significantly lowers the associated environmental toxicity and social impacts linked to mining these critical materials.

End-of-life considerations for K-S battery systems present both challenges and opportunities. The sulfur component is inherently recyclable, with recovery rates potentially exceeding 90% when appropriate structural designs facilitate disassembly. However, current recycling infrastructure requires adaptation to efficiently process potassium-based systems. Structural innovations that incorporate design-for-recycling principles, such as easily separable components and recoverable carbon frameworks, could substantially improve circularity metrics.

Carbon footprint analyses of structurally optimized K-S batteries indicate potential greenhouse gas emission reductions of 35-45% compared to lithium-ion alternatives when considering full lifecycle impacts. This advantage stems primarily from reduced energy requirements during material extraction and processing, coupled with the inherent efficiency gains from optimized electrode structures that extend cycle life and improve energy density.

Water usage represents another critical environmental parameter affected by structural optimizations. Advanced synthesis methods for hierarchical carbon structures in K-S batteries can reduce process water requirements by up to 60% compared to conventional slurry-based electrode manufacturing. This improvement becomes particularly significant in regions facing water scarcity challenges, where battery production facilities may compete with other essential water needs.

Structural optimizations in K-S batteries directly influence their environmental footprint throughout the entire lifecycle. Carbon-based frameworks and hierarchical porous structures not only enhance electrochemical performance but also enable the use of more environmentally benign materials. Recent research indicates that optimized sulfur hosts with rational pore structures can achieve sulfur utilization rates exceeding 80%, substantially reducing material waste during manufacturing processes.

The production phase of structurally optimized K-S batteries demonstrates promising sustainability metrics. Life cycle assessments reveal that carbon-sulfur composite cathodes with engineered interfaces can reduce energy consumption during manufacturing by approximately 30% compared to conventional cathode production methods. Additionally, the elimination of cobalt and nickel from the battery composition significantly lowers the associated environmental toxicity and social impacts linked to mining these critical materials.

End-of-life considerations for K-S battery systems present both challenges and opportunities. The sulfur component is inherently recyclable, with recovery rates potentially exceeding 90% when appropriate structural designs facilitate disassembly. However, current recycling infrastructure requires adaptation to efficiently process potassium-based systems. Structural innovations that incorporate design-for-recycling principles, such as easily separable components and recoverable carbon frameworks, could substantially improve circularity metrics.

Carbon footprint analyses of structurally optimized K-S batteries indicate potential greenhouse gas emission reductions of 35-45% compared to lithium-ion alternatives when considering full lifecycle impacts. This advantage stems primarily from reduced energy requirements during material extraction and processing, coupled with the inherent efficiency gains from optimized electrode structures that extend cycle life and improve energy density.

Water usage represents another critical environmental parameter affected by structural optimizations. Advanced synthesis methods for hierarchical carbon structures in K-S batteries can reduce process water requirements by up to 60% compared to conventional slurry-based electrode manufacturing. This improvement becomes particularly significant in regions facing water scarcity challenges, where battery production facilities may compete with other essential water needs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!