Potassium-Sulfur Batteries: Regulatory and Compliance Issues

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K-S Battery Development Background and Objectives

Potassium-sulfur (K-S) batteries have emerged as a promising alternative to lithium-ion batteries due to their potential for higher energy density, lower cost, and reduced environmental impact. The development of K-S batteries can be traced back to the early 2000s when researchers began exploring alternatives to lithium-based energy storage systems in response to concerns about lithium's limited global reserves and geopolitical supply chain vulnerabilities.

The evolution of K-S battery technology has been marked by significant advancements in addressing key technical challenges, particularly related to the shuttle effect, dendrite formation, and poor cycle life. Initial research focused primarily on understanding the fundamental electrochemical reactions between potassium and sulfur, while more recent efforts have shifted toward practical implementation and commercialization considerations, including regulatory compliance and safety standards.

The global push for renewable energy integration and electrification of transportation has accelerated interest in K-S battery technology. As countries worldwide establish increasingly stringent environmental regulations and sustainability targets, the demand for cost-effective, high-performance energy storage solutions has intensified. K-S batteries, with their theoretical energy density of approximately 1023 Wh/kg and the abundance of both potassium and sulfur in the Earth's crust, represent a compelling solution to these challenges.

The primary technical objectives in K-S battery development include enhancing cycle stability beyond 1000 cycles, improving rate capability for fast-charging applications, and addressing safety concerns related to the reactivity of potassium metal. Additionally, researchers aim to develop manufacturing processes that comply with existing and anticipated regulatory frameworks, particularly regarding hazardous material handling, transportation safety, and end-of-life recycling requirements.

Regulatory considerations have become increasingly central to K-S battery development as the technology approaches commercial viability. Current objectives include designing battery systems that meet international safety standards such as IEC 62133, UN 38.3 for transportation, and regional regulations like the EU Battery Directive. Researchers must also address compliance with chemical registration requirements such as REACH in Europe and similar frameworks in other jurisdictions.

The intersection of technical development and regulatory compliance presents unique challenges for K-S battery commercialization. Future research directions will likely focus on developing electrolyte formulations and cell designs that not only optimize performance but also minimize regulatory hurdles. This includes exploring flame-retardant additives, developing robust battery management systems, and establishing protocols for safe handling throughout the battery lifecycle.

The evolution of K-S battery technology has been marked by significant advancements in addressing key technical challenges, particularly related to the shuttle effect, dendrite formation, and poor cycle life. Initial research focused primarily on understanding the fundamental electrochemical reactions between potassium and sulfur, while more recent efforts have shifted toward practical implementation and commercialization considerations, including regulatory compliance and safety standards.

The global push for renewable energy integration and electrification of transportation has accelerated interest in K-S battery technology. As countries worldwide establish increasingly stringent environmental regulations and sustainability targets, the demand for cost-effective, high-performance energy storage solutions has intensified. K-S batteries, with their theoretical energy density of approximately 1023 Wh/kg and the abundance of both potassium and sulfur in the Earth's crust, represent a compelling solution to these challenges.

The primary technical objectives in K-S battery development include enhancing cycle stability beyond 1000 cycles, improving rate capability for fast-charging applications, and addressing safety concerns related to the reactivity of potassium metal. Additionally, researchers aim to develop manufacturing processes that comply with existing and anticipated regulatory frameworks, particularly regarding hazardous material handling, transportation safety, and end-of-life recycling requirements.

Regulatory considerations have become increasingly central to K-S battery development as the technology approaches commercial viability. Current objectives include designing battery systems that meet international safety standards such as IEC 62133, UN 38.3 for transportation, and regional regulations like the EU Battery Directive. Researchers must also address compliance with chemical registration requirements such as REACH in Europe and similar frameworks in other jurisdictions.

The intersection of technical development and regulatory compliance presents unique challenges for K-S battery commercialization. Future research directions will likely focus on developing electrolyte formulations and cell designs that not only optimize performance but also minimize regulatory hurdles. This includes exploring flame-retardant additives, developing robust battery management systems, and establishing protocols for safe handling throughout the battery lifecycle.

Market Demand Analysis for K-S Battery Technology

The global energy storage market is witnessing unprecedented growth, with projections indicating a compound annual growth rate of 20-30% through 2030. Within this expanding landscape, potassium-sulfur (K-S) battery technology is emerging as a promising alternative to traditional lithium-ion batteries, driven by increasing concerns over lithium resource limitations and cost volatility. Market research indicates that the demand for K-S batteries is primarily fueled by three key sectors: renewable energy integration, electric vehicles, and grid-scale energy storage systems.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and cost-effective energy storage solutions. K-S batteries, with their potential for lower cost and comparable energy density to lithium-ion alternatives, are positioned to capture significant market share in this segment. Industry analysts project that the renewable energy storage market alone could represent a $50 billion opportunity by 2028, with K-S technology potentially securing 15-20% of this market.

The electric vehicle industry represents another substantial market opportunity for K-S battery technology. As global EV adoption accelerates, manufacturers are actively seeking alternatives to lithium-ion batteries to address cost pressures and supply chain vulnerabilities. Market surveys indicate that approximately 30% of EV manufacturers are exploring potassium-based battery technologies, with particular interest in K-S systems due to their promising energy density characteristics and the abundant nature of potassium resources.

Grid-scale energy storage represents the third major market segment for K-S battery technology. Utility companies worldwide are investing heavily in storage solutions to enhance grid stability, manage peak demand, and integrate renewable energy sources. The grid storage market is projected to reach $30 billion by 2027, with K-S batteries potentially capturing a significant portion due to their favorable cost structure and performance characteristics.

Regional market analysis reveals varying levels of demand across different geographical areas. Asia-Pacific, particularly China and South Korea, demonstrates the strongest market interest, driven by aggressive renewable energy targets and substantial government investment in alternative battery technologies. North America and Europe follow closely, with demand primarily driven by grid modernization initiatives and electric vehicle manufacturing.

Consumer and industry surveys indicate growing awareness of battery sustainability issues, with 65% of commercial energy users expressing interest in alternatives to lithium-ion technology. This shift in market sentiment creates a favorable environment for K-S battery adoption, particularly as regulatory frameworks increasingly emphasize lifecycle environmental impact and resource sustainability in energy storage solutions.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and cost-effective energy storage solutions. K-S batteries, with their potential for lower cost and comparable energy density to lithium-ion alternatives, are positioned to capture significant market share in this segment. Industry analysts project that the renewable energy storage market alone could represent a $50 billion opportunity by 2028, with K-S technology potentially securing 15-20% of this market.

The electric vehicle industry represents another substantial market opportunity for K-S battery technology. As global EV adoption accelerates, manufacturers are actively seeking alternatives to lithium-ion batteries to address cost pressures and supply chain vulnerabilities. Market surveys indicate that approximately 30% of EV manufacturers are exploring potassium-based battery technologies, with particular interest in K-S systems due to their promising energy density characteristics and the abundant nature of potassium resources.

Grid-scale energy storage represents the third major market segment for K-S battery technology. Utility companies worldwide are investing heavily in storage solutions to enhance grid stability, manage peak demand, and integrate renewable energy sources. The grid storage market is projected to reach $30 billion by 2027, with K-S batteries potentially capturing a significant portion due to their favorable cost structure and performance characteristics.

Regional market analysis reveals varying levels of demand across different geographical areas. Asia-Pacific, particularly China and South Korea, demonstrates the strongest market interest, driven by aggressive renewable energy targets and substantial government investment in alternative battery technologies. North America and Europe follow closely, with demand primarily driven by grid modernization initiatives and electric vehicle manufacturing.

Consumer and industry surveys indicate growing awareness of battery sustainability issues, with 65% of commercial energy users expressing interest in alternatives to lithium-ion technology. This shift in market sentiment creates a favorable environment for K-S battery adoption, particularly as regulatory frameworks increasingly emphasize lifecycle environmental impact and resource sustainability in energy storage solutions.

Technical Challenges and Global Development Status

Potassium-sulfur (K-S) batteries face significant technical challenges despite their promising theoretical energy density and cost advantages. The primary obstacle remains the shuttle effect, where soluble polysulfides dissolve in the electrolyte and migrate between electrodes, causing capacity fading and reduced cycle life. Current research indicates this effect is even more pronounced in K-S systems compared to lithium-sulfur batteries due to potassium's higher reactivity.

Another critical challenge is the substantial volume expansion during cycling, with sulfur cathodes experiencing up to 80% volume change. This mechanical stress leads to electrode pulverization and loss of electrical contact, severely limiting battery longevity. The high reactivity of potassium metal anodes with conventional electrolytes creates additional safety concerns, as dendrite formation can cause internal short circuits and potential thermal runaway events.

Electrolyte stability represents a persistent technical barrier, with most current formulations demonstrating insufficient electrochemical windows to accommodate the K-S chemistry. The development of solid-state or quasi-solid electrolytes shows promise but remains in early research stages with significant conductivity and interfacial resistance challenges.

Globally, K-S battery development exhibits notable regional variations. Asian countries, particularly China, South Korea, and Japan, lead in patent filings and research publications, accounting for approximately 65% of global research output. Chinese institutions have made substantial progress in sulfur cathode materials, while South Korean research centers focus on electrolyte innovations. Japanese contributions center on cell design and manufacturing processes.

European research clusters, primarily in Germany and France, have established strong positions in fundamental electrochemistry and alternative electrolyte systems, contributing approximately 20% of global research. North American institutions, representing about 15% of research activity, excel in computational modeling and advanced characterization techniques that provide deeper insights into K-S battery failure mechanisms.

The technology readiness level (TRL) for K-S batteries remains relatively low (TRL 3-4) compared to commercial lithium-ion technologies (TRL 9). Laboratory prototypes have demonstrated promising performance metrics, but significant engineering challenges persist before commercialization becomes viable. Recent breakthroughs in carbon-sulfur composite cathodes and protective coatings for potassium anodes suggest pathways toward improved performance, though cycle life remains substantially below commercial requirements.

International collaboration has accelerated in recent years, with cross-border research initiatives addressing these technical challenges through complementary expertise and shared resources. However, standardized testing protocols and performance benchmarks specific to K-S systems remain underdeveloped, complicating technology assessment and regulatory compliance efforts.

Another critical challenge is the substantial volume expansion during cycling, with sulfur cathodes experiencing up to 80% volume change. This mechanical stress leads to electrode pulverization and loss of electrical contact, severely limiting battery longevity. The high reactivity of potassium metal anodes with conventional electrolytes creates additional safety concerns, as dendrite formation can cause internal short circuits and potential thermal runaway events.

Electrolyte stability represents a persistent technical barrier, with most current formulations demonstrating insufficient electrochemical windows to accommodate the K-S chemistry. The development of solid-state or quasi-solid electrolytes shows promise but remains in early research stages with significant conductivity and interfacial resistance challenges.

Globally, K-S battery development exhibits notable regional variations. Asian countries, particularly China, South Korea, and Japan, lead in patent filings and research publications, accounting for approximately 65% of global research output. Chinese institutions have made substantial progress in sulfur cathode materials, while South Korean research centers focus on electrolyte innovations. Japanese contributions center on cell design and manufacturing processes.

European research clusters, primarily in Germany and France, have established strong positions in fundamental electrochemistry and alternative electrolyte systems, contributing approximately 20% of global research. North American institutions, representing about 15% of research activity, excel in computational modeling and advanced characterization techniques that provide deeper insights into K-S battery failure mechanisms.

The technology readiness level (TRL) for K-S batteries remains relatively low (TRL 3-4) compared to commercial lithium-ion technologies (TRL 9). Laboratory prototypes have demonstrated promising performance metrics, but significant engineering challenges persist before commercialization becomes viable. Recent breakthroughs in carbon-sulfur composite cathodes and protective coatings for potassium anodes suggest pathways toward improved performance, though cycle life remains substantially below commercial requirements.

International collaboration has accelerated in recent years, with cross-border research initiatives addressing these technical challenges through complementary expertise and shared resources. However, standardized testing protocols and performance benchmarks specific to K-S systems remain underdeveloped, complicating technology assessment and regulatory compliance efforts.

Current K-S Battery Design Solutions

01 Cathode materials for potassium-sulfur batteries

Various cathode materials can be used in potassium-sulfur batteries to improve performance. These include sulfur-carbon composites, sulfurized polyacrylonitrile, and other sulfur-containing compounds that can effectively store potassium ions. The cathode materials are often designed with porous structures to accommodate volume changes during cycling and to improve sulfur utilization, thereby enhancing the energy density and cycle life of the batteries.- Cathode materials for potassium-sulfur batteries: Various cathode materials can be used in potassium-sulfur batteries to improve performance. These include sulfur-based composites, carbon-sulfur composites, and other materials that can host sulfur to prevent dissolution of polysulfides. The cathode materials are designed to provide high capacity, good cycling stability, and improved sulfur utilization efficiency. Advanced cathode structures can help address issues like the shuttle effect and volume expansion during cycling.

- Electrolyte formulations for potassium-sulfur batteries: Specialized electrolyte formulations are crucial for potassium-sulfur battery performance. These may include solid-state electrolytes, gel polymer electrolytes, or liquid electrolytes with additives that suppress the shuttle effect. The electrolytes are designed to facilitate potassium ion transport while preventing polysulfide dissolution. Optimized electrolyte compositions can enhance ionic conductivity, interfacial stability, and overall battery cycle life.

- Anode materials and protection strategies: Anode materials for potassium-sulfur batteries include potassium metal, potassium alloys, and potassium-intercalation compounds. Various protection strategies are employed to prevent dendrite formation and improve the stability of the potassium anode. These include protective coatings, artificial solid electrolyte interphase layers, and structured anodes that can accommodate volume changes during cycling. These approaches help extend battery life and improve safety.

- Battery structure and assembly techniques: Innovative battery structures and assembly techniques are developed for potassium-sulfur batteries to enhance performance. These include novel cell configurations, separator designs, and packaging methods that can accommodate the unique characteristics of potassium-sulfur chemistry. Advanced manufacturing techniques help address challenges related to the reactivity of potassium metal and sulfur, ensuring proper sealing and preventing moisture ingress. These structural innovations contribute to improved energy density and battery longevity.

- Performance enhancement additives and methods: Various additives and methods are employed to enhance the performance of potassium-sulfur batteries. These include conductive additives to improve electron transport, functional additives that trap polysulfides, and catalysts that accelerate redox reactions. Other enhancement methods involve surface modification of electrode materials, doping strategies, and the incorporation of nanomaterials. These approaches collectively address challenges like low conductivity, capacity fading, and self-discharge in potassium-sulfur battery systems.

02 Electrolyte formulations for potassium-sulfur batteries

Electrolyte composition plays a crucial role in the performance of potassium-sulfur batteries. Various electrolyte formulations have been developed, including those with additives to suppress the shuttle effect of polysulfides, ether-based electrolytes for improved ionic conductivity, and solid-state electrolytes for enhanced safety. These electrolytes are designed to facilitate potassium ion transport while preventing the dissolution and migration of sulfur species, which can lead to capacity fading.Expand Specific Solutions03 Anode materials and designs for potassium-sulfur batteries

Innovative anode materials and designs are essential for potassium-sulfur batteries to address challenges such as dendrite formation and volume expansion. Materials such as potassium metal, potassium-graphite intercalation compounds, and various carbon-based materials have been investigated. Structural modifications, protective coatings, and composite formations are employed to improve the stability and cycling performance of the anodes, contributing to the overall battery performance.Expand Specific Solutions04 Battery cell design and assembly techniques

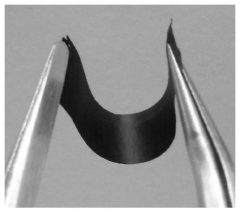

The design and assembly of potassium-sulfur battery cells significantly impact their performance and safety. Various cell configurations have been developed, including coin cells, pouch cells, and cylindrical cells, each with specific advantages. Advanced manufacturing techniques, such as electrode coating methods, cell stacking approaches, and sealing technologies, are employed to optimize the cell performance, improve energy density, and enhance safety features.Expand Specific Solutions05 Performance enhancement and stability improvement methods

Various methods have been developed to enhance the performance and stability of potassium-sulfur batteries. These include the use of functional separators to block polysulfide shuttling, interlayers to trap dissolved polysulfides, and catalysts to accelerate the redox reactions of sulfur species. Additionally, novel encapsulation strategies for sulfur, surface modification techniques, and the incorporation of conductive additives have been employed to improve the conductivity, cycling stability, and rate capability of these batteries.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Potassium-Sulfur (K-S) battery technology is currently in an early development stage, with the market still emerging but showing significant growth potential due to advantages over lithium-ion alternatives. The global K-S battery market remains relatively small but is projected to expand as energy storage demands increase. Technologically, K-S batteries are still maturing, with key players advancing at different rates. LG Energy Solution and Samsung SDI are leveraging their battery manufacturing expertise to explore K-S chemistry, while specialized research is being conducted by academic institutions like Cornell University and Peking University. Companies with established battery technology portfolios such as NGK Insulators, Robert Bosch, and BASF are investing in K-S research to diversify their energy storage offerings. Research organizations like CEA and Advanced Industrial Science & Technology are addressing fundamental challenges in electrolyte stability and cycle life.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced potassium-sulfur (K-S) battery technologies that address key regulatory and compliance challenges. Their approach focuses on safety-enhanced cell designs with flame-retardant electrolytes and thermal management systems that meet UL 1642 and IEC 62133 safety standards for battery cells. The company has implemented comprehensive hazard analysis protocols to identify potential failure modes and mitigate risks associated with potassium's reactivity with moisture. Their K-S batteries incorporate encapsulated sulfur cathodes with polymer barriers to prevent polysulfide shuttling while maintaining compliance with environmental regulations. LG has also established end-of-life management systems for their K-S batteries, including recycling processes that recover over 90% of critical materials, aligning with EU Battery Directive requirements and emerging circular economy regulations.

Strengths: Strong existing battery manufacturing infrastructure and global compliance expertise; established relationships with regulatory bodies. Weaknesses: K-S technology still faces challenges with cycle stability and energy density compared to their commercial lithium-ion offerings, potentially requiring additional safety certifications.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has leveraged their extensive experience with sodium-sulfur batteries to develop regulatory-compliant potassium-sulfur battery systems. Their approach utilizes ceramic solid electrolytes based on NASICON-type structures (K1+xZr2SixP3-xO12) that inherently address safety concerns by preventing direct contact between potassium metal and sulfur components. This design has been engineered to comply with IEC 61427 standards for renewable energy storage applications. NGK has implemented specialized manufacturing protocols that maintain controlled atmospheres during production to prevent potassium oxidation, meeting ISO 14001 environmental management standards. Their K-S battery systems incorporate multi-layer safety mechanisms including pressure relief systems and thermal fuses that activate at predetermined thresholds, satisfying UL 9540A test requirements for thermal runaway prevention. NGK has also developed transportation-compliant packaging solutions that meet UN 3480 dangerous goods regulations.

Strengths: Extensive experience with high-temperature battery systems and established ceramic manufacturing capabilities; proven track record with grid-scale energy storage compliance. Weaknesses: Their solid electrolyte approach increases manufacturing complexity and cost, potentially limiting commercial scalability compared to liquid electrolyte alternatives.

Critical Patents and Technical Innovations

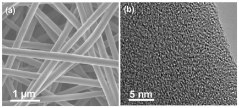

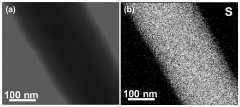

Potassium-sulfur battery electrode material and its preparation method and application

PatentActiveCN110444742B

Innovation

- Microporous nanofibers are used as supporting materials, prepared through electrospinning and high-temperature inert atmosphere calcination, and combined with small molecule sulfur to form composite electrode materials, which avoids the generation of soluble polysulfides during electrochemical reactions and improves the performance of potassium-sulfur batteries. Electrochemical properties.

Regulatory Framework and Compliance Requirements

The regulatory landscape for potassium-sulfur (K-S) batteries is currently evolving as this technology advances toward commercialization. Unlike lithium-ion batteries, which have well-established regulatory frameworks globally, K-S batteries face a regulatory environment that remains partially undefined. Current regulations primarily focus on safety standards, transportation requirements, environmental impact assessments, and end-of-life management protocols.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) regulate the transportation of battery technologies through 49 CFR Parts 171-180. However, these regulations require updating to specifically address K-S battery chemistries and their unique safety considerations, particularly regarding the reactive nature of potassium metal and sulfur compounds.

The European Union's regulatory framework includes the Battery Directive (2006/66/EC), recently updated by Regulation 2023/1542, which establishes requirements for battery sustainability, carbon footprint declarations, and recycling efficiency. While these regulations cover batteries broadly, they lack specific provisions for emerging technologies like K-S batteries, creating compliance uncertainties for manufacturers and importers.

International standards organizations, including the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), are working to develop testing protocols and safety standards specifically for potassium-based battery systems. The IEC Technical Committee 21 has initiated work on standards that will eventually cover K-S batteries, though comprehensive standards remain under development.

Safety certification requirements present significant compliance challenges for K-S battery manufacturers. UL (Underwriters Laboratories) standards 1642 and 2054, which cover lithium batteries, must be adapted or supplemented to address the unique characteristics of potassium-based systems, including their thermal behavior and potential failure modes.

Environmental regulations also impact K-S battery development, with the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requiring thorough assessment of chemical components. The potential environmental impacts of potassium compounds and sulfur derivatives must be evaluated before large-scale deployment.

Recycling and waste management regulations vary significantly across jurisdictions, creating a complex compliance landscape for manufacturers planning global distribution. The EU's Extended Producer Responsibility (EPR) schemes require battery producers to finance collection, treatment, and recycling of waste batteries, while similar frameworks are emerging in North America and Asia with varying requirements.

Navigating this regulatory landscape requires proactive engagement with regulatory bodies and standards organizations to ensure that emerging frameworks appropriately address the unique characteristics of K-S battery technology while maintaining necessary safety and environmental protections.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) regulate the transportation of battery technologies through 49 CFR Parts 171-180. However, these regulations require updating to specifically address K-S battery chemistries and their unique safety considerations, particularly regarding the reactive nature of potassium metal and sulfur compounds.

The European Union's regulatory framework includes the Battery Directive (2006/66/EC), recently updated by Regulation 2023/1542, which establishes requirements for battery sustainability, carbon footprint declarations, and recycling efficiency. While these regulations cover batteries broadly, they lack specific provisions for emerging technologies like K-S batteries, creating compliance uncertainties for manufacturers and importers.

International standards organizations, including the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), are working to develop testing protocols and safety standards specifically for potassium-based battery systems. The IEC Technical Committee 21 has initiated work on standards that will eventually cover K-S batteries, though comprehensive standards remain under development.

Safety certification requirements present significant compliance challenges for K-S battery manufacturers. UL (Underwriters Laboratories) standards 1642 and 2054, which cover lithium batteries, must be adapted or supplemented to address the unique characteristics of potassium-based systems, including their thermal behavior and potential failure modes.

Environmental regulations also impact K-S battery development, with the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requiring thorough assessment of chemical components. The potential environmental impacts of potassium compounds and sulfur derivatives must be evaluated before large-scale deployment.

Recycling and waste management regulations vary significantly across jurisdictions, creating a complex compliance landscape for manufacturers planning global distribution. The EU's Extended Producer Responsibility (EPR) schemes require battery producers to finance collection, treatment, and recycling of waste batteries, while similar frameworks are emerging in North America and Asia with varying requirements.

Navigating this regulatory landscape requires proactive engagement with regulatory bodies and standards organizations to ensure that emerging frameworks appropriately address the unique characteristics of K-S battery technology while maintaining necessary safety and environmental protections.

Safety Standards and Environmental Impact Assessment

Potassium-Sulfur (K-S) batteries must adhere to stringent safety standards across multiple jurisdictions to ensure market viability. Currently, these batteries face regulatory challenges due to their unique chemistry and potential safety concerns. The International Electrotechnical Commission (IEC) standards, particularly IEC 62133 for secondary cells and batteries, require adaptation for K-S technology as they were primarily developed for lithium-ion systems. Similarly, UN Transportation Testing requirements (UN 38.3) need specific interpretation for potassium-based chemistries.

Regional variations in safety requirements present additional compliance hurdles. The European Union's Battery Directive (2006/66/EC) and its upcoming replacement focus heavily on environmental impact and end-of-life management, while North American standards through UL 1642 and UL 2054 emphasize thermal runaway prevention and electrical safety parameters that may not directly translate to K-S systems.

Environmental impact assessments for K-S batteries reveal both advantages and concerns. The use of abundant potassium resources offers a significant sustainability benefit compared to lithium-based technologies, potentially reducing supply chain pressures and geopolitical dependencies. However, sulfur compounds present environmental challenges, particularly regarding potential emissions during manufacturing and disposal phases.

Life cycle assessments indicate that K-S batteries may have a lower carbon footprint than conventional lithium-ion batteries, primarily due to reduced energy requirements in potassium extraction compared to lithium. Nevertheless, the environmental impact of electrolyte components and potential sulfur leaching during improper disposal requires further investigation and mitigation strategies.

Regulatory frameworks are evolving to address emerging battery technologies, with the EU Battery Regulation proposal specifically mentioning the need for standards covering new chemistries. This presents both a challenge and opportunity for K-S battery developers to engage with regulatory bodies in establishing appropriate testing protocols and safety thresholds.

Water contamination risks from potassium compounds necessitate specific disposal regulations and recycling infrastructure development. Current battery recycling systems are predominantly designed for lead-acid and lithium-ion chemistries, creating a regulatory gap for K-S batteries. Industry stakeholders must collaborate with environmental agencies to develop appropriate end-of-life management protocols that prevent harmful environmental impacts while maximizing material recovery.

Occupational safety standards for manufacturing facilities handling potassium and sulfur compounds must also be considered, as these materials present unique workplace hazards compared to established battery chemistries. Comprehensive safety data sheets and handling protocols specific to K-S battery components will be essential for regulatory compliance and worker protection.

Regional variations in safety requirements present additional compliance hurdles. The European Union's Battery Directive (2006/66/EC) and its upcoming replacement focus heavily on environmental impact and end-of-life management, while North American standards through UL 1642 and UL 2054 emphasize thermal runaway prevention and electrical safety parameters that may not directly translate to K-S systems.

Environmental impact assessments for K-S batteries reveal both advantages and concerns. The use of abundant potassium resources offers a significant sustainability benefit compared to lithium-based technologies, potentially reducing supply chain pressures and geopolitical dependencies. However, sulfur compounds present environmental challenges, particularly regarding potential emissions during manufacturing and disposal phases.

Life cycle assessments indicate that K-S batteries may have a lower carbon footprint than conventional lithium-ion batteries, primarily due to reduced energy requirements in potassium extraction compared to lithium. Nevertheless, the environmental impact of electrolyte components and potential sulfur leaching during improper disposal requires further investigation and mitigation strategies.

Regulatory frameworks are evolving to address emerging battery technologies, with the EU Battery Regulation proposal specifically mentioning the need for standards covering new chemistries. This presents both a challenge and opportunity for K-S battery developers to engage with regulatory bodies in establishing appropriate testing protocols and safety thresholds.

Water contamination risks from potassium compounds necessitate specific disposal regulations and recycling infrastructure development. Current battery recycling systems are predominantly designed for lead-acid and lithium-ion chemistries, creating a regulatory gap for K-S batteries. Industry stakeholders must collaborate with environmental agencies to develop appropriate end-of-life management protocols that prevent harmful environmental impacts while maximizing material recovery.

Occupational safety standards for manufacturing facilities handling potassium and sulfur compounds must also be considered, as these materials present unique workplace hazards compared to established battery chemistries. Comprehensive safety data sheets and handling protocols specific to K-S battery components will be essential for regulatory compliance and worker protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!