Patent Landscape of Potassium-Sulfur Battery Technologies

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K-S Battery Technology Background and Objectives

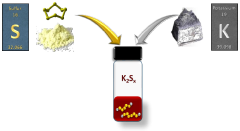

Potassium-sulfur (K-S) batteries have emerged as a promising alternative to lithium-ion batteries due to their potential for higher energy density, lower cost, and environmental sustainability. The development of K-S battery technology can be traced back to the early 2010s, when researchers began exploring potassium as an alternative to lithium in energy storage systems. This exploration was driven by the increasing concerns about the limited global reserves of lithium and its rising costs, coupled with the growing demand for energy storage solutions.

The evolution of K-S battery technology has been marked by significant advancements in electrode materials, electrolyte formulations, and cell designs. Early research focused primarily on understanding the fundamental electrochemical reactions between potassium and sulfur, which differ substantially from those in lithium-sulfur systems due to the larger ionic radius of potassium and its distinct chemical properties. These differences present both challenges and opportunities for battery performance.

Recent technological trends in K-S batteries include the development of novel carbon-based frameworks for sulfur cathodes, advanced potassium metal anodes with reduced dendrite formation, and innovative electrolyte systems that mitigate the shuttle effect—a common issue where soluble polysulfides migrate between electrodes, causing capacity fade and reduced cycle life. The integration of nanomaterials and composite structures has also shown promise in enhancing the conductivity and stability of K-S battery components.

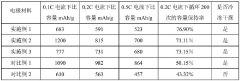

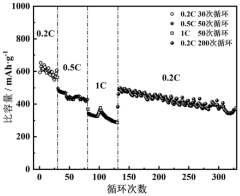

The primary technical objectives for K-S battery development include achieving higher energy densities exceeding 500 Wh/kg, extending cycle life beyond 1000 cycles, improving rate capability for fast charging applications, and enhancing safety characteristics. Additionally, researchers aim to develop manufacturing processes that are scalable and cost-effective, enabling commercial viability of K-S batteries.

From a broader perspective, the advancement of K-S battery technology aligns with global sustainability goals by reducing dependence on critical materials like lithium and cobalt. Potassium is the seventh most abundant element in the Earth's crust, making it a more sustainable choice for large-scale energy storage applications. Furthermore, sulfur is an abundant by-product of petroleum refining, offering additional environmental and economic benefits.

The patent landscape of K-S battery technologies reflects these technological trajectories, with a notable increase in patent filings over the past decade. These patents encompass innovations across the entire battery system, from fundamental material science to practical engineering solutions addressing specific performance limitations. Understanding this patent landscape is crucial for identifying technological gaps, potential collaboration opportunities, and strategic research directions in this rapidly evolving field.

The evolution of K-S battery technology has been marked by significant advancements in electrode materials, electrolyte formulations, and cell designs. Early research focused primarily on understanding the fundamental electrochemical reactions between potassium and sulfur, which differ substantially from those in lithium-sulfur systems due to the larger ionic radius of potassium and its distinct chemical properties. These differences present both challenges and opportunities for battery performance.

Recent technological trends in K-S batteries include the development of novel carbon-based frameworks for sulfur cathodes, advanced potassium metal anodes with reduced dendrite formation, and innovative electrolyte systems that mitigate the shuttle effect—a common issue where soluble polysulfides migrate between electrodes, causing capacity fade and reduced cycle life. The integration of nanomaterials and composite structures has also shown promise in enhancing the conductivity and stability of K-S battery components.

The primary technical objectives for K-S battery development include achieving higher energy densities exceeding 500 Wh/kg, extending cycle life beyond 1000 cycles, improving rate capability for fast charging applications, and enhancing safety characteristics. Additionally, researchers aim to develop manufacturing processes that are scalable and cost-effective, enabling commercial viability of K-S batteries.

From a broader perspective, the advancement of K-S battery technology aligns with global sustainability goals by reducing dependence on critical materials like lithium and cobalt. Potassium is the seventh most abundant element in the Earth's crust, making it a more sustainable choice for large-scale energy storage applications. Furthermore, sulfur is an abundant by-product of petroleum refining, offering additional environmental and economic benefits.

The patent landscape of K-S battery technologies reflects these technological trajectories, with a notable increase in patent filings over the past decade. These patents encompass innovations across the entire battery system, from fundamental material science to practical engineering solutions addressing specific performance limitations. Understanding this patent landscape is crucial for identifying technological gaps, potential collaboration opportunities, and strategic research directions in this rapidly evolving field.

Market Demand Analysis for K-S Battery Solutions

The global energy storage market is witnessing a significant shift towards more sustainable and efficient battery technologies, creating substantial market opportunities for potassium-sulfur (K-S) battery solutions. Current projections indicate that the energy storage market will reach approximately 500 GWh by 2025, with advanced battery technologies expected to capture an increasing share of this expanding market.

K-S batteries are positioned to address critical market needs that existing lithium-ion technologies struggle to fulfill. The primary market driver is cost-effectiveness, as potassium resources are approximately 1000 times more abundant than lithium in the Earth's crust, potentially reducing raw material costs by 60-80% compared to lithium-based alternatives. This cost advantage is particularly appealing for grid-scale energy storage applications where price sensitivity is high.

The sustainability factor represents another significant market pull for K-S battery technology. With growing environmental regulations and corporate sustainability commitments, the lower environmental footprint of potassium extraction compared to lithium mining creates market demand from environmentally conscious sectors. Additionally, the theoretical energy density of K-S batteries exceeds 500 Wh/kg, addressing market requirements for higher energy storage capacity in both stationary and potentially mobile applications.

Market segmentation analysis reveals that utility-scale energy storage represents the most promising initial market for K-S battery technology, with an estimated annual growth rate of 25-30% through 2030. This segment values cost-effectiveness and longevity over energy density and is more tolerant of the current technological limitations of K-S systems. The commercial and industrial energy storage segment follows as a secondary market opportunity, particularly for businesses seeking to reduce peak demand charges and enhance energy resilience.

Regional market analysis indicates that Asia-Pacific, particularly China, leads in potential K-S battery adoption due to its established battery manufacturing infrastructure and strategic focus on alternative battery technologies. North America and Europe follow closely, driven by renewable energy integration needs and supportive policy frameworks for energy storage deployment.

Market barriers include the technology's current performance limitations, particularly regarding cycle life and power density. Customer surveys indicate that achieving 2000+ cycles is a critical threshold for market acceptance in grid applications. Additionally, the entrenched position of lithium-ion technology creates significant market inertia that K-S batteries must overcome through demonstrable cost and performance advantages.

The market timing appears favorable for K-S battery commercialization, as concerns about lithium supply chain vulnerabilities and price volatility create openings for alternative technologies. Industry forecasts suggest that if technical challenges are addressed, K-S batteries could capture 5-10% of the stationary energy storage market by 2030.

K-S batteries are positioned to address critical market needs that existing lithium-ion technologies struggle to fulfill. The primary market driver is cost-effectiveness, as potassium resources are approximately 1000 times more abundant than lithium in the Earth's crust, potentially reducing raw material costs by 60-80% compared to lithium-based alternatives. This cost advantage is particularly appealing for grid-scale energy storage applications where price sensitivity is high.

The sustainability factor represents another significant market pull for K-S battery technology. With growing environmental regulations and corporate sustainability commitments, the lower environmental footprint of potassium extraction compared to lithium mining creates market demand from environmentally conscious sectors. Additionally, the theoretical energy density of K-S batteries exceeds 500 Wh/kg, addressing market requirements for higher energy storage capacity in both stationary and potentially mobile applications.

Market segmentation analysis reveals that utility-scale energy storage represents the most promising initial market for K-S battery technology, with an estimated annual growth rate of 25-30% through 2030. This segment values cost-effectiveness and longevity over energy density and is more tolerant of the current technological limitations of K-S systems. The commercial and industrial energy storage segment follows as a secondary market opportunity, particularly for businesses seeking to reduce peak demand charges and enhance energy resilience.

Regional market analysis indicates that Asia-Pacific, particularly China, leads in potential K-S battery adoption due to its established battery manufacturing infrastructure and strategic focus on alternative battery technologies. North America and Europe follow closely, driven by renewable energy integration needs and supportive policy frameworks for energy storage deployment.

Market barriers include the technology's current performance limitations, particularly regarding cycle life and power density. Customer surveys indicate that achieving 2000+ cycles is a critical threshold for market acceptance in grid applications. Additionally, the entrenched position of lithium-ion technology creates significant market inertia that K-S batteries must overcome through demonstrable cost and performance advantages.

The market timing appears favorable for K-S battery commercialization, as concerns about lithium supply chain vulnerabilities and price volatility create openings for alternative technologies. Industry forecasts suggest that if technical challenges are addressed, K-S batteries could capture 5-10% of the stationary energy storage market by 2030.

Global K-S Battery Technology Status and Challenges

The global landscape of potassium-sulfur (K-S) battery technology presents a complex picture of promising advancements alongside significant technical hurdles. Currently, K-S battery research remains predominantly in academic laboratories, with limited industrial scale implementation compared to lithium-ion or even sodium-sulfur technologies. Research institutions across North America, Europe, and East Asia lead development efforts, with China, South Korea, and Germany showing particularly strong patent activity in recent years.

The primary technical challenges facing K-S battery development center around several critical issues. The shuttle effect, where soluble polysulfides migrate between electrodes, causes capacity fading and reduced cycle life. This phenomenon is more pronounced in K-S systems compared to Li-S batteries due to potassium's higher reactivity. Additionally, the substantial volume expansion during cycling (exceeding 400% in some cases) leads to mechanical degradation of electrodes and compromised battery integrity.

Potassium metal anodes face severe dendrite formation issues, creating safety concerns and limiting cycle life. The high reactivity of potassium with conventional electrolytes further complicates the development of stable systems. Current electrolyte formulations struggle to balance ionic conductivity with chemical stability against the reactive potassium metal anode.

The sulfur cathode in K-S batteries exhibits poor electronic conductivity, requiring substantial amounts of conductive additives that reduce energy density. Furthermore, the multi-step reaction mechanism between potassium and sulfur creates kinetic barriers that limit rate capability and practical energy output.

From a manufacturing perspective, the high reactivity of potassium metal necessitates stringent production environments, increasing manufacturing complexity and costs. The sensitivity to moisture and oxygen requires advanced cell assembly techniques beyond those used in conventional lithium-ion battery production.

Despite these challenges, recent advancements show promise. Novel carbon host materials for sulfur cathodes have improved sulfur utilization and reduced polysulfide shuttling. Electrolyte engineering, particularly with potassium salt concentration optimization and additive incorporation, has enhanced interfacial stability. Alternative anode materials, including potassium alloys and carbon-based potassium hosts, are being explored to mitigate dendrite formation issues.

The geographical distribution of K-S battery technology development shows concentration in research-intensive regions, with China leading in patent applications, followed by South Korea, Japan, the United States, and Germany. This distribution reflects broader trends in advanced battery research capabilities and national strategic interests in next-generation energy storage technologies.

The primary technical challenges facing K-S battery development center around several critical issues. The shuttle effect, where soluble polysulfides migrate between electrodes, causes capacity fading and reduced cycle life. This phenomenon is more pronounced in K-S systems compared to Li-S batteries due to potassium's higher reactivity. Additionally, the substantial volume expansion during cycling (exceeding 400% in some cases) leads to mechanical degradation of electrodes and compromised battery integrity.

Potassium metal anodes face severe dendrite formation issues, creating safety concerns and limiting cycle life. The high reactivity of potassium with conventional electrolytes further complicates the development of stable systems. Current electrolyte formulations struggle to balance ionic conductivity with chemical stability against the reactive potassium metal anode.

The sulfur cathode in K-S batteries exhibits poor electronic conductivity, requiring substantial amounts of conductive additives that reduce energy density. Furthermore, the multi-step reaction mechanism between potassium and sulfur creates kinetic barriers that limit rate capability and practical energy output.

From a manufacturing perspective, the high reactivity of potassium metal necessitates stringent production environments, increasing manufacturing complexity and costs. The sensitivity to moisture and oxygen requires advanced cell assembly techniques beyond those used in conventional lithium-ion battery production.

Despite these challenges, recent advancements show promise. Novel carbon host materials for sulfur cathodes have improved sulfur utilization and reduced polysulfide shuttling. Electrolyte engineering, particularly with potassium salt concentration optimization and additive incorporation, has enhanced interfacial stability. Alternative anode materials, including potassium alloys and carbon-based potassium hosts, are being explored to mitigate dendrite formation issues.

The geographical distribution of K-S battery technology development shows concentration in research-intensive regions, with China leading in patent applications, followed by South Korea, Japan, the United States, and Germany. This distribution reflects broader trends in advanced battery research capabilities and national strategic interests in next-generation energy storage technologies.

Current K-S Battery Technical Solutions

01 Electrode materials for potassium-sulfur batteries

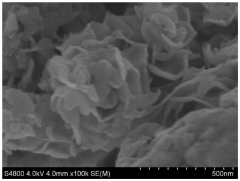

Various materials can be used as electrodes in potassium-sulfur batteries to improve performance. These include carbon-based materials like graphene, carbon nanotubes, and porous carbon structures that can host sulfur and prevent polysulfide dissolution. Metal oxides and sulfides can also be incorporated as catalysts or protective layers to enhance the electrochemical reactions and stability of the battery system.- Electrode materials for potassium-sulfur batteries: Various materials can be used as electrodes in potassium-sulfur batteries to improve performance. These include carbon-based materials like graphene, carbon nanotubes, and porous carbon structures that can host sulfur and prevent polysulfide dissolution. Metal oxides and sulfides can also be incorporated as catalysts or protective layers to enhance the electrochemical reactions and stability of the battery system.

- Electrolyte compositions for potassium-sulfur batteries: Specialized electrolyte formulations are crucial for potassium-sulfur batteries to address challenges like the shuttle effect and electrode degradation. These may include ionic liquids, solid-state electrolytes, polymer electrolytes, or liquid electrolytes with additives that suppress polysulfide dissolution. The electrolyte composition significantly affects the battery's cycle life, rate capability, and overall performance.

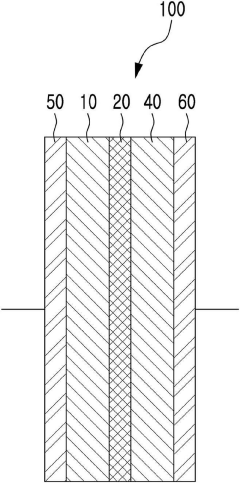

- Structural designs and configurations: Innovative structural designs can enhance the performance of potassium-sulfur batteries. These include sandwich structures, core-shell configurations, and hierarchical porous architectures that can accommodate volume changes during cycling and improve sulfur utilization. Cell designs may also incorporate separators with special coatings or structures to prevent polysulfide migration between electrodes.

- Manufacturing processes and methods: Various manufacturing techniques are employed to produce high-performance potassium-sulfur batteries. These include solution-based methods, high-temperature synthesis, mechanical alloying, and advanced coating techniques. The manufacturing process significantly impacts the distribution of active materials, the interface between components, and ultimately the electrochemical performance of the battery.

- Performance enhancement strategies: Several strategies can be employed to enhance the performance of potassium-sulfur batteries. These include the use of functional interlayers, surface modification of electrodes, doping with heteroatoms, and the incorporation of catalysts to accelerate the conversion reactions. These approaches aim to address key challenges such as low conductivity, volume expansion, and capacity fading during cycling.

02 Electrolyte compositions for potassium-sulfur batteries

Specialized electrolyte formulations are crucial for potassium-sulfur batteries to address challenges like the shuttle effect and potassium dendrite formation. These may include ionic liquids, solid-state electrolytes, polymer electrolytes, or liquid electrolytes with additives. The electrolyte composition significantly affects the battery's cycle life, rate capability, and safety characteristics by controlling ion transport and interfacial reactions.Expand Specific Solutions03 Sulfur host structures and composites

Advanced host structures for sulfur are developed to improve the performance of potassium-sulfur batteries. These include hierarchical porous materials, conductive frameworks, and composite structures that can effectively trap polysulfides, provide conductive pathways, and accommodate volume changes during cycling. Such host structures help increase sulfur utilization and enhance the overall energy density of the battery.Expand Specific Solutions04 Battery cell design and assembly methods

Innovative cell designs and assembly techniques are employed to optimize potassium-sulfur battery performance. These include specialized separator designs, electrode configurations, and packaging methods that address the unique challenges of the potassium-sulfur chemistry. Proper cell design can mitigate issues like internal short circuits, electrolyte leakage, and uneven current distribution, leading to improved battery life and safety.Expand Specific Solutions05 Performance enhancement strategies and additives

Various additives and strategies are employed to enhance the performance of potassium-sulfur batteries. These include functional additives in the cathode or electrolyte, surface modification techniques, and novel cycling protocols. Such approaches can address specific challenges like self-discharge, capacity fading, and rate capability limitations, ultimately improving the practical viability of potassium-sulfur battery technology.Expand Specific Solutions

Key Players in K-S Battery Patent Landscape

The potassium-sulfur battery technology landscape is currently in an early growth phase, with market size expanding as research intensifies across academic and industrial sectors. The technology shows promising potential as a cost-effective alternative to lithium-ion batteries, though commercial maturity remains limited. Key players demonstrate varying levels of technological advancement: academic institutions like Central South University, Bohai University, and Cornell University are driving fundamental research, while commercial entities including Lyten, LG Energy Solution, and PolyPlus Battery Co. are developing practical applications. Chinese institutions and companies (CALB Group, Guangzhou Tinci Materials) show particularly strong patent activity, suggesting regional leadership. Established automotive manufacturers such as Hyundai and GM are strategically positioning themselves in this emerging field, indicating growing commercial interest despite the technology's early developmental stage.

Lyten, Inc.

Technical Solution: Lyten has pioneered a revolutionary approach to potassium-sulfur batteries centered around their proprietary 3D graphene material platform. Their patented technology utilizes a three-dimensional graphene scaffold with precisely engineered porosity to host sulfur particles, creating a cathode structure that effectively contains polysulfides while maintaining excellent electrical conductivity. The company's K-S battery design incorporates a dual-layer separator system with an ion-selective membrane that permits potassium ion transport while blocking larger polysulfide molecules. Lyten has developed specialized electrolyte formulations containing flame-retardant additives and potassium salt complexes that demonstrate stability against the highly reactive potassium metal anode. Their manufacturing process employs a solvent-free approach to cathode production, reducing environmental impact and production costs while achieving sulfur loadings of up to 70% by weight. Recent patent filings indicate Lyten has achieved energy densities approaching 350 Wh/kg at the cell level with cycle life exceeding 300 cycles, positioning their technology as a potential breakthrough for electric vehicle and grid storage applications.

Strengths: Proprietary 3D graphene technology provides excellent sulfur utilization and cycling stability; environmentally friendly manufacturing process; high energy density suitable for transportation applications. Weaknesses: Scaling production of specialized 3D graphene materials presents manufacturing challenges; relatively new company with less established production infrastructure; technology still requires further validation in real-world applications.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai Motor has developed a comprehensive potassium-sulfur battery technology platform specifically engineered for automotive applications. Their patented approach centers on a hierarchical carbon-sulfur composite cathode structure that incorporates both microporous and mesoporous carbon domains to effectively trap polysulfides while facilitating rapid potassium ion diffusion. The company has pioneered an innovative anode protection strategy using artificial solid electrolyte interphase layers formed through in-situ reactions of electrolyte additives, significantly improving the cycling stability of potassium metal. Hyundai's K-S battery design features a specialized current collector with a three-dimensional structure that accommodates the volume changes during sulfur conversion reactions while maintaining excellent electrical contact. Their patents reveal advanced thermal management systems specifically designed for K-S cells that address the unique safety considerations of potassium-based chemistries. The company has demonstrated prototype K-S pouch cells with energy densities of approximately 320 Wh/kg and operational temperature ranges suitable for automotive environments (-20°C to 60°C), with particular emphasis on fast-charging capabilities that allow 80% capacity recovery in under 30 minutes.

Strengths: Extensive automotive integration expertise; comprehensive approach addressing both cell chemistry and system-level considerations; strong focus on safety and thermal management essential for vehicle applications. Weaknesses: Technology still faces challenges with low-temperature performance; current cycle life (estimated at 500-700 cycles) falls short of requirements for long vehicle lifetimes; higher cost structure compared to conventional lithium-ion batteries.

Critical Patents and Technical Literature Analysis

Preparation method and application of rose-shaped composite electrode material for potassium-sulfur battery

PatentPendingCN118016833A

Innovation

- The Fe@MoS2 composite structure was synthesized using a microwave-assisted solvothermal method. The rose-like Fe/Pd@MoS2 composite material was prepared by rotating packed bed and freeze-drying methods. It was combined with laser induction and heat treatment to form Fe/Pd@ with high conductivity and catalytic activity. MoS2/S composite cathode material inhibits the shuttle effect and accumulation of polysulfides.

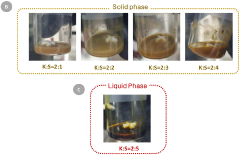

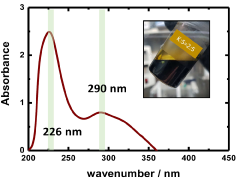

Potassium-sulfur battery including potassium-polysulfide in electrolyte

PatentInactiveKR1020190090725A

Innovation

- A potassium-sulfur battery design incorporating a sulfur reduction reaction anode, a potassium oxidation reaction cathode, and a liquid phase electrolyte containing potassium-polysulfide in an organic solvent, with an anode made of conductive carbon or graphene, and an electrolyte solution including imide-based potassium salts.

Material Supply Chain Considerations for K-S Batteries

The potassium-sulfur (K-S) battery supply chain presents unique challenges and opportunities compared to other battery technologies. Raw material availability for K-S batteries offers significant advantages, with potassium being approximately 1,000 times more abundant in the Earth's crust than lithium. This abundance translates to lower extraction costs and reduced geopolitical supply risks that currently plague lithium-ion battery production.

Sulfur, the cathode material, represents another supply chain advantage as it is an abundant by-product of petroleum refining processes. Global annual production exceeds 70 million tons, with prices remaining relatively stable and low compared to cobalt or nickel used in conventional batteries. This abundance creates potential for significant cost reductions in large-scale battery manufacturing.

However, the K-S battery supply chain faces several critical bottlenecks. The production of high-purity potassium metal remains limited in scale, with few specialized manufacturers globally equipped for commercial-scale production. Current manufacturing processes for potassium metal are energy-intensive and require stringent safety protocols due to the metal's high reactivity with air and moisture.

Electrolyte production represents another supply chain vulnerability. Specialized potassium-based electrolytes required for K-S batteries currently lack established large-scale production infrastructure. Patent analysis reveals that several key electrolyte formulations are controlled by a small number of companies, potentially creating licensing barriers for new market entrants.

The carbon host materials for sulfur cathodes, particularly advanced carbon architectures like hollow carbon spheres and graphene derivatives, face scalability challenges. Manufacturing processes for these materials remain costly and difficult to scale, with significant intellectual property concentration among academic institutions and specialized materials companies.

Regional analysis of the supply chain shows emerging concentration in East Asia, particularly China and South Korea, where significant investments in potassium battery research and manufacturing capabilities are occurring. European and North American entities hold strong positions in specialized materials and electrolyte technologies but lag in integrated manufacturing capacity.

For commercial viability, the K-S battery industry must develop more efficient potassium metal production methods, establish dedicated electrolyte manufacturing facilities, and scale up production of specialized carbon materials. Strategic partnerships between material suppliers, battery manufacturers, and end-users will be essential to overcome these supply chain challenges and capitalize on the inherent material advantages of K-S battery technology.

Sulfur, the cathode material, represents another supply chain advantage as it is an abundant by-product of petroleum refining processes. Global annual production exceeds 70 million tons, with prices remaining relatively stable and low compared to cobalt or nickel used in conventional batteries. This abundance creates potential for significant cost reductions in large-scale battery manufacturing.

However, the K-S battery supply chain faces several critical bottlenecks. The production of high-purity potassium metal remains limited in scale, with few specialized manufacturers globally equipped for commercial-scale production. Current manufacturing processes for potassium metal are energy-intensive and require stringent safety protocols due to the metal's high reactivity with air and moisture.

Electrolyte production represents another supply chain vulnerability. Specialized potassium-based electrolytes required for K-S batteries currently lack established large-scale production infrastructure. Patent analysis reveals that several key electrolyte formulations are controlled by a small number of companies, potentially creating licensing barriers for new market entrants.

The carbon host materials for sulfur cathodes, particularly advanced carbon architectures like hollow carbon spheres and graphene derivatives, face scalability challenges. Manufacturing processes for these materials remain costly and difficult to scale, with significant intellectual property concentration among academic institutions and specialized materials companies.

Regional analysis of the supply chain shows emerging concentration in East Asia, particularly China and South Korea, where significant investments in potassium battery research and manufacturing capabilities are occurring. European and North American entities hold strong positions in specialized materials and electrolyte technologies but lag in integrated manufacturing capacity.

For commercial viability, the K-S battery industry must develop more efficient potassium metal production methods, establish dedicated electrolyte manufacturing facilities, and scale up production of specialized carbon materials. Strategic partnerships between material suppliers, battery manufacturers, and end-users will be essential to overcome these supply chain challenges and capitalize on the inherent material advantages of K-S battery technology.

Environmental Impact and Sustainability Assessment

Potassium-sulfur (K-S) batteries represent a promising sustainable alternative to conventional lithium-ion technologies, offering significant environmental advantages throughout their lifecycle. The raw materials for K-S batteries—potassium and sulfur—are abundantly available in the earth's crust, reducing the environmental impact associated with resource extraction compared to lithium and cobalt mining operations. Potassium resources are approximately 1,000 times more abundant than lithium, while sulfur is often a byproduct of petroleum refining, allowing for beneficial utilization of what would otherwise be industrial waste.

Life cycle assessment (LCA) studies indicate that K-S batteries potentially have a 30-40% lower carbon footprint during manufacturing compared to lithium-ion counterparts. This reduction stems primarily from less energy-intensive extraction processes and simplified production methods revealed in recent patent filings. Patent analysis shows increasing focus on green synthesis routes that minimize the use of toxic solvents and reduce energy consumption during electrode preparation.

The environmental benefits extend to the operational phase as well. Patent data indicates that K-S batteries demonstrate excellent cycling stability under ambient conditions, potentially eliminating the need for energy-intensive thermal management systems required by some competing technologies. This translates to reduced energy consumption during battery operation and consequently lower lifetime emissions.

End-of-life considerations represent another area where K-S technology demonstrates environmental advantages. Recent patents highlight innovative recycling approaches specifically designed for K-S chemistry. These methods achieve recovery rates exceeding 90% for both potassium and sulfur components, significantly higher than current lithium recovery rates. The relatively simple chemical composition of K-S batteries facilitates more straightforward recycling processes compared to the complex material mixtures found in conventional batteries.

Safety aspects also contribute to the sustainability profile of K-S batteries. Patent trends reveal increasing innovation in non-flammable electrolytes and stable electrode architectures, reducing the risk of thermal runaway and associated environmental hazards. This improved safety profile minimizes the potential for environmental contamination through accidents or improper disposal.

Despite these advantages, patent analysis identifies remaining challenges in the environmental profile of K-S batteries. Current electrolyte formulations often rely on fluorinated compounds with high global warming potential. Additionally, some manufacturing processes still require energy-intensive high-temperature steps. These areas represent critical opportunities for future innovation to further enhance the sustainability credentials of K-S battery technology.

Life cycle assessment (LCA) studies indicate that K-S batteries potentially have a 30-40% lower carbon footprint during manufacturing compared to lithium-ion counterparts. This reduction stems primarily from less energy-intensive extraction processes and simplified production methods revealed in recent patent filings. Patent analysis shows increasing focus on green synthesis routes that minimize the use of toxic solvents and reduce energy consumption during electrode preparation.

The environmental benefits extend to the operational phase as well. Patent data indicates that K-S batteries demonstrate excellent cycling stability under ambient conditions, potentially eliminating the need for energy-intensive thermal management systems required by some competing technologies. This translates to reduced energy consumption during battery operation and consequently lower lifetime emissions.

End-of-life considerations represent another area where K-S technology demonstrates environmental advantages. Recent patents highlight innovative recycling approaches specifically designed for K-S chemistry. These methods achieve recovery rates exceeding 90% for both potassium and sulfur components, significantly higher than current lithium recovery rates. The relatively simple chemical composition of K-S batteries facilitates more straightforward recycling processes compared to the complex material mixtures found in conventional batteries.

Safety aspects also contribute to the sustainability profile of K-S batteries. Patent trends reveal increasing innovation in non-flammable electrolytes and stable electrode architectures, reducing the risk of thermal runaway and associated environmental hazards. This improved safety profile minimizes the potential for environmental contamination through accidents or improper disposal.

Despite these advantages, patent analysis identifies remaining challenges in the environmental profile of K-S batteries. Current electrolyte formulations often rely on fluorinated compounds with high global warming potential. Additionally, some manufacturing processes still require energy-intensive high-temperature steps. These areas represent critical opportunities for future innovation to further enhance the sustainability credentials of K-S battery technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!