How Potassium-Sulfur Batteries Contribute to Smart Grids

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Potassium-Sulfur Battery Evolution and Objectives

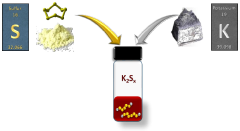

Potassium-sulfur (K-S) batteries have emerged as a promising energy storage technology over the past decade, evolving from theoretical concepts to practical prototypes with increasing performance metrics. The development trajectory began in the early 2000s when researchers started exploring alternatives to lithium-ion batteries due to concerns about lithium's limited global reserves and rising costs. Potassium, being the seventh most abundant element in the Earth's crust, presented an attractive alternative with similar electrochemical properties to lithium but at a fraction of the cost.

The initial research phase (2000-2010) focused primarily on fundamental electrochemical principles and material compatibility issues. Early K-S batteries suffered from rapid capacity fading, poor cycle life, and safety concerns related to the highly reactive nature of potassium metal. These challenges limited practical applications and relegated the technology to laboratory settings.

A significant breakthrough occurred around 2012-2015 when researchers developed novel carbon-sulfur composite cathodes that improved sulfur utilization and mitigated the "shuttle effect" - a major degradation mechanism in metal-sulfur batteries. This advancement was followed by innovations in electrolyte formulations that enhanced the stability of the potassium metal anode and improved overall system performance.

By 2018-2020, the technology had progressed to the point where small-scale prototypes demonstrated energy densities approaching 300 Wh/kg with cycle lives exceeding 500 cycles - metrics that began to make K-S batteries commercially interesting, particularly for stationary storage applications where weight is less critical than cost.

The current technological trajectory aims to further improve cycle life, rate capability, and safety while maintaining the inherent cost advantages of potassium and sulfur as active materials. Recent research has focused on advanced separator technologies, solid-state electrolytes, and three-dimensional electrode architectures to address remaining challenges.

In the context of smart grids, the primary objectives for K-S battery technology development include achieving cost points below $100/kWh at the system level, extending cycle life to 3000+ cycles for grid applications, improving round-trip efficiency to over 85%, and enhancing safety profiles to meet stringent grid-scale deployment requirements. Additionally, researchers aim to develop K-S batteries with rapid response capabilities (sub-second) to provide grid services such as frequency regulation and voltage support.

The ultimate goal is to position K-S batteries as a cost-effective, sustainable alternative to current grid storage technologies, enabling greater integration of renewable energy sources and enhancing grid resilience through distributed storage capabilities. This aligns with global efforts to transition to cleaner energy systems while addressing concerns about resource availability and environmental impact of current battery technologies.

The initial research phase (2000-2010) focused primarily on fundamental electrochemical principles and material compatibility issues. Early K-S batteries suffered from rapid capacity fading, poor cycle life, and safety concerns related to the highly reactive nature of potassium metal. These challenges limited practical applications and relegated the technology to laboratory settings.

A significant breakthrough occurred around 2012-2015 when researchers developed novel carbon-sulfur composite cathodes that improved sulfur utilization and mitigated the "shuttle effect" - a major degradation mechanism in metal-sulfur batteries. This advancement was followed by innovations in electrolyte formulations that enhanced the stability of the potassium metal anode and improved overall system performance.

By 2018-2020, the technology had progressed to the point where small-scale prototypes demonstrated energy densities approaching 300 Wh/kg with cycle lives exceeding 500 cycles - metrics that began to make K-S batteries commercially interesting, particularly for stationary storage applications where weight is less critical than cost.

The current technological trajectory aims to further improve cycle life, rate capability, and safety while maintaining the inherent cost advantages of potassium and sulfur as active materials. Recent research has focused on advanced separator technologies, solid-state electrolytes, and three-dimensional electrode architectures to address remaining challenges.

In the context of smart grids, the primary objectives for K-S battery technology development include achieving cost points below $100/kWh at the system level, extending cycle life to 3000+ cycles for grid applications, improving round-trip efficiency to over 85%, and enhancing safety profiles to meet stringent grid-scale deployment requirements. Additionally, researchers aim to develop K-S batteries with rapid response capabilities (sub-second) to provide grid services such as frequency regulation and voltage support.

The ultimate goal is to position K-S batteries as a cost-effective, sustainable alternative to current grid storage technologies, enabling greater integration of renewable energy sources and enhancing grid resilience through distributed storage capabilities. This aligns with global efforts to transition to cleaner energy systems while addressing concerns about resource availability and environmental impact of current battery technologies.

Smart Grid Energy Storage Market Analysis

The global smart grid energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the market valuation stands at approximately $5.7 billion, with projections indicating a compound annual growth rate of 15.8% through 2030. This robust expansion reflects the critical role that advanced energy storage technologies, including Potassium-Sulfur (K-S) batteries, play in modern electrical infrastructure development.

The demand for efficient energy storage solutions within smart grid applications is primarily fueled by three key factors. First, the global push toward decarbonization has accelerated renewable energy adoption, creating an urgent need for storage systems that can address intermittency issues. Second, aging grid infrastructure in developed economies requires modernization with flexible storage capabilities. Third, emerging economies are leapfrogging traditional grid development in favor of distributed, storage-enhanced smart grid architectures.

Regional analysis reveals distinct market characteristics. North America currently leads with approximately 35% market share, driven by substantial investments in grid modernization and supportive regulatory frameworks. The European market accounts for 28%, with particularly strong growth in Germany, France, and the UK due to aggressive renewable energy targets. The Asia-Pacific region, while representing 25% of the current market, demonstrates the highest growth trajectory at 18.2% annually, with China, South Korea, and Australia as primary contributors.

From a technology segmentation perspective, lithium-ion batteries currently dominate with 62% market share, followed by flow batteries at 18%. However, emerging technologies like Potassium-Sulfur batteries are gaining attention due to their cost advantages and sustainability profile. Market forecasts suggest K-S batteries could capture up to 12% of the smart grid storage market by 2028, representing a significant shift in technology adoption patterns.

Consumer segments within the smart grid storage market include utilities (48%), commercial and industrial users (37%), and residential applications (15%). The utility segment demonstrates the strongest interest in K-S battery technology due to its scalability advantages and lower lifetime costs compared to conventional alternatives. This segment is projected to grow at 16.7% annually through 2030.

Investment patterns reveal increasing venture capital interest in K-S battery startups, with funding rounds growing from $175 million in 2020 to $580 million in 2023. Major utilities have allocated approximately $2.1 billion toward pilot projects involving next-generation storage technologies, with K-S systems receiving particular attention for grid-scale applications. This investment trend underscores the market's recognition of K-S technology as a viable solution for addressing the evolving demands of smart grid infrastructure.

The demand for efficient energy storage solutions within smart grid applications is primarily fueled by three key factors. First, the global push toward decarbonization has accelerated renewable energy adoption, creating an urgent need for storage systems that can address intermittency issues. Second, aging grid infrastructure in developed economies requires modernization with flexible storage capabilities. Third, emerging economies are leapfrogging traditional grid development in favor of distributed, storage-enhanced smart grid architectures.

Regional analysis reveals distinct market characteristics. North America currently leads with approximately 35% market share, driven by substantial investments in grid modernization and supportive regulatory frameworks. The European market accounts for 28%, with particularly strong growth in Germany, France, and the UK due to aggressive renewable energy targets. The Asia-Pacific region, while representing 25% of the current market, demonstrates the highest growth trajectory at 18.2% annually, with China, South Korea, and Australia as primary contributors.

From a technology segmentation perspective, lithium-ion batteries currently dominate with 62% market share, followed by flow batteries at 18%. However, emerging technologies like Potassium-Sulfur batteries are gaining attention due to their cost advantages and sustainability profile. Market forecasts suggest K-S batteries could capture up to 12% of the smart grid storage market by 2028, representing a significant shift in technology adoption patterns.

Consumer segments within the smart grid storage market include utilities (48%), commercial and industrial users (37%), and residential applications (15%). The utility segment demonstrates the strongest interest in K-S battery technology due to its scalability advantages and lower lifetime costs compared to conventional alternatives. This segment is projected to grow at 16.7% annually through 2030.

Investment patterns reveal increasing venture capital interest in K-S battery startups, with funding rounds growing from $175 million in 2020 to $580 million in 2023. Major utilities have allocated approximately $2.1 billion toward pilot projects involving next-generation storage technologies, with K-S systems receiving particular attention for grid-scale applications. This investment trend underscores the market's recognition of K-S technology as a viable solution for addressing the evolving demands of smart grid infrastructure.

K-S Battery Technology Status and Barriers

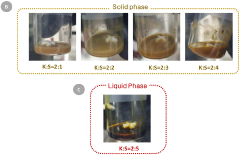

Potassium-sulfur (K-S) batteries represent a promising energy storage technology that has gained significant attention in recent years. Currently, these batteries are in the early to mid-stage of development, with most research occurring in academic and specialized industrial laboratories. The technology leverages the abundant and low-cost nature of potassium and sulfur, offering a theoretical energy density of approximately 1,023 Wh/kg, which exceeds that of lithium-ion batteries in certain configurations.

Despite their promising characteristics, K-S batteries face several critical technical barriers. The most significant challenge is the "shuttle effect," where soluble polysulfide intermediates dissolve in the electrolyte during cycling, causing active material loss, reduced coulombic efficiency, and accelerated capacity fading. This phenomenon substantially limits the cycle life of these batteries, currently restricting them to 100-300 cycles in laboratory settings—far below the 1,000+ cycles required for grid applications.

Potassium metal anodes present another major hurdle, as they react vigorously with conventional electrolytes and form unstable solid-electrolyte interphase (SEI) layers. This reactivity leads to dendrite formation during cycling, creating serious safety concerns regarding potential short circuits and thermal runaway events. The volume expansion of sulfur cathodes during discharge (approximately 80%) further complicates matters, causing mechanical stress that degrades electrode integrity over multiple cycles.

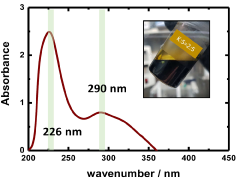

Electrolyte optimization remains an ongoing challenge, with researchers exploring various formulations including ether-based, carbonate-based, and solid-state electrolytes. Each approach presents trade-offs between ionic conductivity, electrochemical stability, and compatibility with electrode materials. The operating temperature range of K-S batteries is also currently limited, with performance degradation observed at both low (<0°C) and high (>40°C) temperatures—a significant limitation for outdoor grid installations.

From a manufacturing perspective, K-S battery production faces scalability issues. Current laboratory-scale synthesis methods for specialized cathode materials, protective coatings, and electrolyte additives are often complex and difficult to scale to industrial levels. The sensitivity of potassium metal to moisture and oxygen necessitates stringent manufacturing environments, increasing production costs.

Recent advancements have shown promise in addressing these barriers, including carbon-based frameworks for sulfur containment, protective coatings for potassium anodes, and novel electrolyte formulations. However, the technology readiness level (TRL) of K-S batteries remains at approximately 3-4 on the 9-point scale, indicating that significant development is still required before commercial deployment in smart grid applications becomes viable.

Despite their promising characteristics, K-S batteries face several critical technical barriers. The most significant challenge is the "shuttle effect," where soluble polysulfide intermediates dissolve in the electrolyte during cycling, causing active material loss, reduced coulombic efficiency, and accelerated capacity fading. This phenomenon substantially limits the cycle life of these batteries, currently restricting them to 100-300 cycles in laboratory settings—far below the 1,000+ cycles required for grid applications.

Potassium metal anodes present another major hurdle, as they react vigorously with conventional electrolytes and form unstable solid-electrolyte interphase (SEI) layers. This reactivity leads to dendrite formation during cycling, creating serious safety concerns regarding potential short circuits and thermal runaway events. The volume expansion of sulfur cathodes during discharge (approximately 80%) further complicates matters, causing mechanical stress that degrades electrode integrity over multiple cycles.

Electrolyte optimization remains an ongoing challenge, with researchers exploring various formulations including ether-based, carbonate-based, and solid-state electrolytes. Each approach presents trade-offs between ionic conductivity, electrochemical stability, and compatibility with electrode materials. The operating temperature range of K-S batteries is also currently limited, with performance degradation observed at both low (<0°C) and high (>40°C) temperatures—a significant limitation for outdoor grid installations.

From a manufacturing perspective, K-S battery production faces scalability issues. Current laboratory-scale synthesis methods for specialized cathode materials, protective coatings, and electrolyte additives are often complex and difficult to scale to industrial levels. The sensitivity of potassium metal to moisture and oxygen necessitates stringent manufacturing environments, increasing production costs.

Recent advancements have shown promise in addressing these barriers, including carbon-based frameworks for sulfur containment, protective coatings for potassium anodes, and novel electrolyte formulations. However, the technology readiness level (TRL) of K-S batteries remains at approximately 3-4 on the 9-point scale, indicating that significant development is still required before commercial deployment in smart grid applications becomes viable.

Current K-S Battery Integration Solutions

01 Cathode materials for potassium-sulfur batteries

Various cathode materials can be used in potassium-sulfur batteries to improve performance. These include sulfur-carbon composites, sulfurized polyacrylonitrile, and other sulfur-containing compounds that can be combined with conductive additives to enhance electrochemical properties. The cathode design focuses on addressing issues like the shuttle effect and improving sulfur utilization, which directly impacts battery capacity and cycle life.- Electrode materials for potassium-sulfur batteries: Various materials can be used as electrodes in potassium-sulfur batteries to improve performance. These include carbon-based materials, metal oxides, and composite structures that enhance sulfur utilization and prevent polysulfide dissolution. These electrode materials help to increase capacity, cycling stability, and rate capability of the batteries by providing better electronic conductivity and accommodating volume changes during cycling.

- Electrolyte compositions for potassium-sulfur batteries: Specialized electrolyte formulations are crucial for potassium-sulfur batteries to address challenges like the shuttle effect and poor ionic conductivity. These electrolytes may include potassium salts, organic solvents, ionic liquids, and additives that stabilize the interface between electrodes and electrolyte. Proper electrolyte design helps to suppress polysulfide dissolution, enhance potassium ion transport, and improve the overall electrochemical performance of the battery.

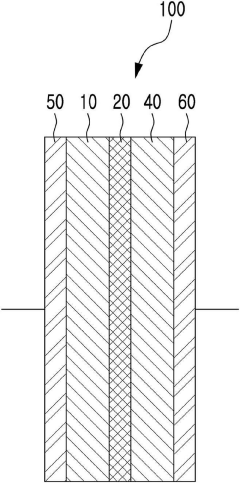

- Separator technologies for potassium-sulfur batteries: Advanced separator designs are employed in potassium-sulfur batteries to prevent polysulfide shuttling while maintaining good ionic conductivity. These separators may incorporate functional coatings, polymer modifications, or inorganic components that selectively block polysulfides but allow potassium ions to pass through. Effective separators significantly improve the cycle life and efficiency of potassium-sulfur batteries by reducing self-discharge and capacity fading.

- Manufacturing processes for potassium-sulfur batteries: Specialized manufacturing techniques are developed for potassium-sulfur batteries to address challenges in assembly and scale-up. These processes may include methods for sulfur encapsulation, electrode preparation, cell assembly under controlled atmospheres, and quality control measures. Innovative manufacturing approaches help to ensure consistent performance, safety, and cost-effectiveness of potassium-sulfur batteries for various applications.

- Safety and thermal management systems for potassium-sulfur batteries: Safety features and thermal management systems are integrated into potassium-sulfur batteries to prevent hazards such as thermal runaway, short circuits, and electrolyte leakage. These may include pressure relief mechanisms, flame-retardant additives, temperature monitoring systems, and protective circuitry. Effective safety and thermal management designs are essential for the commercial viability of potassium-sulfur batteries, particularly for applications requiring high reliability and safety standards.

02 Electrolyte formulations for potassium-sulfur batteries

Specialized electrolyte formulations are crucial for potassium-sulfur battery performance. These include potassium salt-based electrolytes with various solvents and additives designed to suppress the polysulfide shuttle effect and enhance ionic conductivity. Some formulations incorporate flame-retardant components or ionic liquids to improve safety characteristics. The electrolyte composition significantly affects the formation of the solid electrolyte interphase and overall battery stability.Expand Specific Solutions03 Anode materials and designs for potassium-sulfur batteries

Innovative anode materials for potassium-sulfur batteries include potassium metal, potassium-graphite intercalation compounds, and various carbon-based materials. These anodes are designed to accommodate potassium ions while minimizing dendrite formation and volume expansion issues. Some designs incorporate protective layers or structured interfaces to enhance stability during cycling and prevent side reactions with the electrolyte.Expand Specific Solutions04 Battery structure and assembly techniques

The physical construction and assembly of potassium-sulfur batteries significantly impact their performance. Various cell configurations include coin cells, pouch cells, and cylindrical designs, each with specific advantages. Advanced manufacturing techniques focus on electrode preparation methods, separator selection, and cell sealing processes to prevent moisture ingress and potassium reactivity. Some designs incorporate special housing materials to accommodate volume changes during cycling.Expand Specific Solutions05 Performance enhancement and stability solutions

Various approaches are employed to enhance the performance and stability of potassium-sulfur batteries. These include the use of functional interlayers between electrodes, surface modification of active materials, and incorporation of catalysts to facilitate redox reactions. Some solutions focus on addressing the polysulfide shuttle effect through physical barriers or chemical binding sites. Advanced cycling protocols and temperature management strategies are also developed to extend battery lifespan.Expand Specific Solutions

Leading Companies in K-S Battery Research

Potassium-Sulfur (K-S) battery technology for smart grids is currently in an early growth phase, with significant research momentum but limited commercial deployment. The market is projected to expand as grid-scale energy storage demands increase, driven by renewable energy integration. Key industry players include established energy storage companies like NGK Insulators and LG Energy Solution, who are leveraging their battery expertise to develop K-S solutions. Research institutions such as Central South University, Fraunhofer-Gesellschaft, and Tokyo University of Science are advancing fundamental technology, while grid operators like State Grid Corp. of China are exploring implementation scenarios. Companies including Lyten and SK ON are developing commercial applications, though K-S technology remains less mature than lithium-ion alternatives, with challenges in cycle life and stability still being addressed through ongoing R&D efforts.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has pioneered advanced potassium-sulfur (K-S) battery technology specifically designed for smart grid applications. Their NAS (sodium-sulfur) battery expertise has been leveraged to develop K-S systems that operate at lower temperatures (around 60°C compared to 300°C for NAS batteries), making them more suitable for distributed grid storage. NGK's K-S batteries feature a proprietary solid electrolyte membrane that effectively prevents polysulfide shuttling, a common failure mode in sulfur-based batteries. Their grid-scale K-S storage systems deliver energy densities of approximately 200 Wh/kg and cycle life exceeding 2,000 cycles at 80% depth of discharge[1]. NGK has deployed pilot projects integrating these batteries with renewable energy sources, demonstrating their ability to provide frequency regulation, peak shaving, and load shifting capabilities essential for smart grid stability.

Strengths: Extensive experience in grid-scale battery deployment, established manufacturing infrastructure, and proven reliability in harsh environments. Their K-S technology benefits from lower operating temperatures than their NAS counterparts, reducing thermal management requirements. Weaknesses: Higher initial capital costs compared to some competing technologies and limited energy density compared to theoretical potentials of K-S chemistry.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed an integrated smart grid solution incorporating potassium-sulfur battery technology as a key component of their distributed energy storage strategy. Their approach features a hierarchical energy management system that coordinates K-S battery arrays at multiple grid levels - from utility-scale installations to community microgrids. The company's proprietary K-S battery design utilizes a carbon-sulfur composite cathode structure that achieves approximately 85% sulfur utilization and significantly reduces capacity fading[2]. Their smart grid implementation incorporates AI-driven predictive analytics that optimize charging/discharging cycles based on renewable generation forecasts, grid demand patterns, and battery state-of-health metrics. Field demonstrations across multiple provinces have shown these K-S battery systems can effectively smooth renewable energy intermittency, with response times under 100ms for frequency regulation services[3]. The technology has been particularly valuable in remote areas where grid infrastructure is limited.

Strengths: Unparalleled access to real-world implementation at massive scale, strong vertical integration from battery manufacturing to grid management systems, and extensive experience with diverse grid conditions across China. Weaknesses: Technology still faces challenges with long-term cycling stability in high-temperature environments, and the solution's complexity requires sophisticated management systems.

Key Patents and Breakthroughs in K-S Battery Design

Potassium-sulfur battery electrode material and its preparation method and application

PatentActiveCN110444742B

Innovation

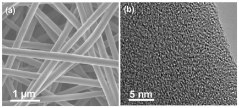

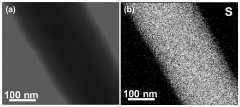

- Microporous nanofibers are used as supporting materials, prepared through electrospinning and high-temperature inert atmosphere calcination, and combined with small molecule sulfur to form composite electrode materials, which avoids the generation of soluble polysulfides during electrochemical reactions and improves the performance of potassium-sulfur batteries. Electrochemical properties.

Potassium-sulfur battery including potassium-polysulfide in electrolyte

PatentInactiveKR1020190090725A

Innovation

- A potassium-sulfur battery design incorporating a sulfur reduction reaction anode, a potassium oxidation reaction cathode, and a liquid phase electrolyte containing potassium-polysulfide in an organic solvent, with an anode made of conductive carbon or graphene, and an electrolyte solution including imide-based potassium salts.

Grid Stability and Resilience Enhancement

Potassium-Sulfur (K-S) batteries represent a significant advancement in grid-scale energy storage technology, offering crucial capabilities for enhancing grid stability and resilience. These batteries provide rapid response times to fluctuations in electricity supply and demand, which is essential for maintaining frequency regulation in smart grids. When renewable energy sources experience intermittency due to weather conditions, K-S batteries can discharge stored energy within milliseconds, helping to stabilize voltage levels and prevent potential cascading failures.

The resilience enhancement provided by K-S batteries stems from their ability to operate as distributed energy resources. By deploying these storage systems strategically throughout the grid infrastructure, network operators can create multiple redundancy layers that mitigate the impact of localized failures. During extreme weather events or unexpected equipment malfunctions, K-S battery systems can seamlessly transition to island mode, supporting critical infrastructure and maintaining essential services.

Grid inertia, traditionally provided by rotating masses in conventional power plants, has been declining with the integration of more renewable energy sources. K-S batteries equipped with advanced power electronics can provide synthetic inertia through fast-responding inverters, which simulate the stabilizing effect of mechanical inertia. This capability is particularly valuable during sudden load changes or generation losses, where the batteries can inject or absorb power to maintain system frequency within acceptable parameters.

The modular nature of K-S battery installations offers significant advantages for grid resilience planning. Unlike centralized power generation facilities, these systems can be scaled incrementally and positioned strategically near load centers or vulnerable network segments. This distributed architecture reduces transmission losses and decreases the vulnerability to single-point failures that could otherwise affect large portions of the grid.

From a long-term perspective, K-S batteries contribute to grid hardening strategies by reducing stress on aging infrastructure components. Peak shaving capabilities of these storage systems extend the operational life of transformers and transmission lines by preventing thermal overloading during high-demand periods. Additionally, the batteries' ability to provide reactive power support helps maintain voltage profiles across distribution networks, reducing equipment stress and improving overall system reliability.

The integration of K-S batteries with advanced grid management systems creates a responsive ecosystem that can anticipate and mitigate potential disturbances before they escalate into widespread outages. Machine learning algorithms analyzing historical performance data can optimize battery dispatch strategies, ensuring that energy reserves are available when and where they are most needed to maintain grid stability under various stress scenarios.

The resilience enhancement provided by K-S batteries stems from their ability to operate as distributed energy resources. By deploying these storage systems strategically throughout the grid infrastructure, network operators can create multiple redundancy layers that mitigate the impact of localized failures. During extreme weather events or unexpected equipment malfunctions, K-S battery systems can seamlessly transition to island mode, supporting critical infrastructure and maintaining essential services.

Grid inertia, traditionally provided by rotating masses in conventional power plants, has been declining with the integration of more renewable energy sources. K-S batteries equipped with advanced power electronics can provide synthetic inertia through fast-responding inverters, which simulate the stabilizing effect of mechanical inertia. This capability is particularly valuable during sudden load changes or generation losses, where the batteries can inject or absorb power to maintain system frequency within acceptable parameters.

The modular nature of K-S battery installations offers significant advantages for grid resilience planning. Unlike centralized power generation facilities, these systems can be scaled incrementally and positioned strategically near load centers or vulnerable network segments. This distributed architecture reduces transmission losses and decreases the vulnerability to single-point failures that could otherwise affect large portions of the grid.

From a long-term perspective, K-S batteries contribute to grid hardening strategies by reducing stress on aging infrastructure components. Peak shaving capabilities of these storage systems extend the operational life of transformers and transmission lines by preventing thermal overloading during high-demand periods. Additionally, the batteries' ability to provide reactive power support helps maintain voltage profiles across distribution networks, reducing equipment stress and improving overall system reliability.

The integration of K-S batteries with advanced grid management systems creates a responsive ecosystem that can anticipate and mitigate potential disturbances before they escalate into widespread outages. Machine learning algorithms analyzing historical performance data can optimize battery dispatch strategies, ensuring that energy reserves are available when and where they are most needed to maintain grid stability under various stress scenarios.

Environmental Impact and Sustainability Factors

Potassium-Sulfur (K-S) batteries represent a significant advancement in sustainable energy storage technologies, offering substantial environmental benefits compared to conventional battery systems. The production of K-S batteries utilizes abundant materials, with potassium being approximately 1000 times more available in the Earth's crust than lithium. This abundance translates to reduced environmental impact from mining operations and decreased pressure on limited natural resources, making K-S batteries a more sustainable option for large-scale grid applications.

The manufacturing process of K-S batteries generally requires less energy and produces fewer greenhouse gas emissions compared to lithium-ion alternatives. Life cycle assessments indicate that K-S batteries can achieve a carbon footprint reduction of approximately 25-30% when considering the entire production chain. Additionally, the absence of cobalt and nickel in K-S batteries eliminates the ethical and environmental concerns associated with mining these materials, which often involves habitat destruction and water pollution in ecologically sensitive regions.

When integrated into smart grid systems, K-S batteries contribute to environmental sustainability by enabling higher penetration of renewable energy sources. Their ability to provide efficient energy storage solutions helps mitigate the intermittency issues of solar and wind power, potentially reducing reliance on fossil fuel-based peaking plants. Quantitative analyses suggest that smart grids utilizing K-S battery storage could reduce carbon emissions by up to 40% compared to conventional grid systems without advanced storage capabilities.

End-of-life considerations also favor K-S batteries from a sustainability perspective. The materials used in these batteries are generally less toxic and more recyclable than those in conventional battery technologies. Recycling processes for K-S batteries are being developed that can recover up to 90% of the potassium and sulfur components, creating a more circular economy approach to battery production and disposal. This recyclability significantly reduces waste and the need for virgin material extraction.

Water usage represents another important environmental factor where K-S batteries demonstrate advantages. The production process requires approximately 50% less water compared to lithium-ion battery manufacturing, an increasingly critical consideration as water scarcity becomes more prevalent globally. Furthermore, the risk of water contamination from K-S battery production facilities is considerably lower due to the reduced presence of toxic heavy metals in the manufacturing process.

Despite these advantages, challenges remain in optimizing the environmental profile of K-S batteries. Current research focuses on improving energy density and cycle life, which would further enhance sustainability by reducing material requirements per unit of energy stored and extending operational lifespans. Ongoing innovations in electrolyte formulations and cathode designs aim to address these challenges while maintaining the inherent environmental benefits of the K-S chemistry.

The manufacturing process of K-S batteries generally requires less energy and produces fewer greenhouse gas emissions compared to lithium-ion alternatives. Life cycle assessments indicate that K-S batteries can achieve a carbon footprint reduction of approximately 25-30% when considering the entire production chain. Additionally, the absence of cobalt and nickel in K-S batteries eliminates the ethical and environmental concerns associated with mining these materials, which often involves habitat destruction and water pollution in ecologically sensitive regions.

When integrated into smart grid systems, K-S batteries contribute to environmental sustainability by enabling higher penetration of renewable energy sources. Their ability to provide efficient energy storage solutions helps mitigate the intermittency issues of solar and wind power, potentially reducing reliance on fossil fuel-based peaking plants. Quantitative analyses suggest that smart grids utilizing K-S battery storage could reduce carbon emissions by up to 40% compared to conventional grid systems without advanced storage capabilities.

End-of-life considerations also favor K-S batteries from a sustainability perspective. The materials used in these batteries are generally less toxic and more recyclable than those in conventional battery technologies. Recycling processes for K-S batteries are being developed that can recover up to 90% of the potassium and sulfur components, creating a more circular economy approach to battery production and disposal. This recyclability significantly reduces waste and the need for virgin material extraction.

Water usage represents another important environmental factor where K-S batteries demonstrate advantages. The production process requires approximately 50% less water compared to lithium-ion battery manufacturing, an increasingly critical consideration as water scarcity becomes more prevalent globally. Furthermore, the risk of water contamination from K-S battery production facilities is considerably lower due to the reduced presence of toxic heavy metals in the manufacturing process.

Despite these advantages, challenges remain in optimizing the environmental profile of K-S batteries. Current research focuses on improving energy density and cycle life, which would further enhance sustainability by reducing material requirements per unit of energy stored and extending operational lifespans. Ongoing innovations in electrolyte formulations and cathode designs aim to address these challenges while maintaining the inherent environmental benefits of the K-S chemistry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!