Safety Standards for Potassium-Sulfur Battery Manufacturing

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K-S Battery Safety Evolution and Objectives

Potassium-Sulfur (K-S) battery technology has emerged as a promising alternative to lithium-ion batteries due to its potential for higher energy density, lower cost, and reduced environmental impact. The evolution of safety standards in K-S battery manufacturing can be traced back to the early 2010s when research on potassium-based energy storage systems began gaining momentum. Initially, safety considerations were largely adapted from lithium-sulfur and sodium-sulfur battery protocols, which proved inadequate due to potassium's unique chemical properties and reactivity.

The mid-2010s marked a critical turning point with several laboratory incidents highlighting the specific safety challenges of K-S chemistry, particularly potassium's violent reaction with water and the formation of highly flammable hydrogen gas. These incidents prompted the International Electrochemical Commission (IEC) to establish the first specialized working group on potassium-based battery safety in 2017, focusing on developing preliminary guidelines for laboratory-scale research.

By 2019, as K-S battery technology moved from laboratory to pilot production, industry consortiums began collaborating with regulatory bodies to develop more comprehensive safety frameworks. The European Battery Alliance and the U.S. Department of Energy's Battery500 Consortium incorporated specific K-S battery safety protocols into their research roadmaps, acknowledging the unique challenges posed by potassium's higher reactivity compared to lithium.

The current landscape of K-S battery safety standards remains fragmented, with different regions adopting varied approaches. Asian manufacturers, particularly in South Korea and China, have implemented stringent in-house safety protocols, while European standards have focused more on environmental considerations alongside safety. North American approaches have emphasized performance testing under extreme conditions.

The primary objective of evolving K-S battery safety standards is to establish a unified global framework that addresses the full lifecycle of these batteries—from raw material handling to manufacturing, transportation, use, and eventual recycling. This framework aims to mitigate risks while enabling innovation and commercialization of this promising technology.

Secondary objectives include developing specialized testing methodologies that accurately assess K-S battery safety under various conditions, creating standardized emergency response protocols for incidents involving K-S batteries, and establishing clear labeling and handling requirements that communicate risks effectively across the supply chain. These standards must balance rigorous safety requirements with practical implementation considerations to avoid creating insurmountable barriers to market entry.

The mid-2010s marked a critical turning point with several laboratory incidents highlighting the specific safety challenges of K-S chemistry, particularly potassium's violent reaction with water and the formation of highly flammable hydrogen gas. These incidents prompted the International Electrochemical Commission (IEC) to establish the first specialized working group on potassium-based battery safety in 2017, focusing on developing preliminary guidelines for laboratory-scale research.

By 2019, as K-S battery technology moved from laboratory to pilot production, industry consortiums began collaborating with regulatory bodies to develop more comprehensive safety frameworks. The European Battery Alliance and the U.S. Department of Energy's Battery500 Consortium incorporated specific K-S battery safety protocols into their research roadmaps, acknowledging the unique challenges posed by potassium's higher reactivity compared to lithium.

The current landscape of K-S battery safety standards remains fragmented, with different regions adopting varied approaches. Asian manufacturers, particularly in South Korea and China, have implemented stringent in-house safety protocols, while European standards have focused more on environmental considerations alongside safety. North American approaches have emphasized performance testing under extreme conditions.

The primary objective of evolving K-S battery safety standards is to establish a unified global framework that addresses the full lifecycle of these batteries—from raw material handling to manufacturing, transportation, use, and eventual recycling. This framework aims to mitigate risks while enabling innovation and commercialization of this promising technology.

Secondary objectives include developing specialized testing methodologies that accurately assess K-S battery safety under various conditions, creating standardized emergency response protocols for incidents involving K-S batteries, and establishing clear labeling and handling requirements that communicate risks effectively across the supply chain. These standards must balance rigorous safety requirements with practical implementation considerations to avoid creating insurmountable barriers to market entry.

Market Demand Analysis for K-S Battery Technology

The global energy storage market is witnessing a significant shift towards more sustainable and efficient battery technologies, creating substantial market opportunities for potassium-sulfur (K-S) batteries. Current projections indicate that the grid energy storage market alone will exceed $30 billion by 2030, with advanced battery technologies capturing an increasing share of this expanding market.

K-S battery technology addresses critical limitations of existing lithium-ion batteries, particularly in terms of resource availability and cost. With potassium being approximately 1000 times more abundant in the Earth's crust than lithium, K-S batteries present a compelling alternative for large-scale energy storage applications where cost considerations outweigh energy density requirements.

Market research indicates growing demand across multiple sectors. The stationary energy storage sector shows particular promise, with utility companies seeking cost-effective solutions for grid stabilization, renewable energy integration, and peak shaving applications. The renewable energy sector's expansion, projected to grow at 8-10% annually through 2030, directly drives demand for affordable large-scale storage solutions like K-S batteries.

Industrial applications represent another significant market segment, with manufacturing facilities increasingly implementing on-site energy storage to reduce peak demand charges and improve energy resilience. This sector values the potential safety improvements that properly standardized K-S batteries could offer over some existing technologies.

Consumer electronics manufacturers are also expressing interest in K-S technology as a potential alternative to lithium-ion batteries, particularly for applications where cost sensitivity outweighs strict volume constraints. However, this market segment demands rigorous safety standards before widespread adoption can occur.

Regional market analysis reveals varying levels of demand. Asia-Pacific leads in potential adoption, driven by China's aggressive energy storage targets and substantial investments in battery manufacturing infrastructure. Europe follows closely, with its strong regulatory push toward renewable energy integration creating favorable conditions for advanced battery technologies.

Market barriers primarily center on safety concerns and lack of standardization. Potential customers across all segments consistently cite safety as a primary consideration in battery technology selection. The development of comprehensive safety standards for K-S battery manufacturing would directly address this market barrier, potentially accelerating adoption rates by 15-20% according to industry analysts.

The competitive landscape includes several established battery manufacturers exploring K-S technology alongside specialized startups focused exclusively on this chemistry. Market forecasts suggest that companies establishing early leadership in safety standards development will gain significant competitive advantages as the technology matures toward commercialization.

K-S battery technology addresses critical limitations of existing lithium-ion batteries, particularly in terms of resource availability and cost. With potassium being approximately 1000 times more abundant in the Earth's crust than lithium, K-S batteries present a compelling alternative for large-scale energy storage applications where cost considerations outweigh energy density requirements.

Market research indicates growing demand across multiple sectors. The stationary energy storage sector shows particular promise, with utility companies seeking cost-effective solutions for grid stabilization, renewable energy integration, and peak shaving applications. The renewable energy sector's expansion, projected to grow at 8-10% annually through 2030, directly drives demand for affordable large-scale storage solutions like K-S batteries.

Industrial applications represent another significant market segment, with manufacturing facilities increasingly implementing on-site energy storage to reduce peak demand charges and improve energy resilience. This sector values the potential safety improvements that properly standardized K-S batteries could offer over some existing technologies.

Consumer electronics manufacturers are also expressing interest in K-S technology as a potential alternative to lithium-ion batteries, particularly for applications where cost sensitivity outweighs strict volume constraints. However, this market segment demands rigorous safety standards before widespread adoption can occur.

Regional market analysis reveals varying levels of demand. Asia-Pacific leads in potential adoption, driven by China's aggressive energy storage targets and substantial investments in battery manufacturing infrastructure. Europe follows closely, with its strong regulatory push toward renewable energy integration creating favorable conditions for advanced battery technologies.

Market barriers primarily center on safety concerns and lack of standardization. Potential customers across all segments consistently cite safety as a primary consideration in battery technology selection. The development of comprehensive safety standards for K-S battery manufacturing would directly address this market barrier, potentially accelerating adoption rates by 15-20% according to industry analysts.

The competitive landscape includes several established battery manufacturers exploring K-S technology alongside specialized startups focused exclusively on this chemistry. Market forecasts suggest that companies establishing early leadership in safety standards development will gain significant competitive advantages as the technology matures toward commercialization.

Current Safety Challenges in K-S Battery Manufacturing

Potassium-sulfur (K-S) battery manufacturing faces significant safety challenges due to the highly reactive nature of potassium metal and sulfur compounds. The primary concern is potassium's extreme reactivity with water and oxygen, which can lead to spontaneous combustion and violent reactions when exposed to air or moisture. Manufacturing facilities must maintain strictly controlled environments with extremely low humidity levels (<0.1 ppm water content) and near-zero oxygen concentrations, presenting substantial technical challenges for production scale-up.

Thermal management represents another critical safety concern. K-S batteries can experience thermal runaway events when operating outside safe temperature ranges (typically between -20°C and 60°C). During manufacturing, precise temperature control is essential, particularly during electrode preparation and cell assembly processes where temperature fluctuations can trigger dangerous exothermic reactions between potassium and sulfur components.

Electrolyte handling introduces additional hazards, as most K-S battery designs utilize organic or ionic liquid electrolytes that are often flammable and toxic. These materials require specialized containment systems, ventilation infrastructure, and personal protective equipment protocols. Current manufacturing facilities struggle to implement comprehensive safety systems that can effectively manage vapor accumulation and potential leakage scenarios.

Material compatibility issues further complicate manufacturing safety. Potassium's aggressive chemical nature means it can react with many common manufacturing materials, including certain metals, polymers, and sealing compounds. This necessitates careful selection of production equipment and infrastructure components, with specialized materials that resist corrosion and degradation when exposed to battery components.

Waste management and disposal present ongoing challenges. Manufacturing byproducts, rejected cells, and production scrap contain reactive materials that cannot be disposed of through conventional waste streams. Current facilities lack standardized protocols for neutralizing reactive components and safely processing manufacturing waste, creating environmental and safety risks throughout the product lifecycle.

Worker safety protocols remain underdeveloped compared to more established battery technologies. The unique hazards of K-S battery production require specialized training, emergency response procedures, and medical protocols that differ significantly from those used in lithium-ion manufacturing. The industry currently faces a knowledge gap in best practices for worker protection and emergency management specific to potassium-based battery systems.

Regulatory frameworks have not kept pace with K-S battery development, resulting in inconsistent safety standards across different regions. Manufacturers must navigate a complex landscape of chemical safety regulations, transportation restrictions, and workplace safety requirements that were not specifically designed for potassium-sulfur technology, creating compliance uncertainties and potential safety gaps.

Thermal management represents another critical safety concern. K-S batteries can experience thermal runaway events when operating outside safe temperature ranges (typically between -20°C and 60°C). During manufacturing, precise temperature control is essential, particularly during electrode preparation and cell assembly processes where temperature fluctuations can trigger dangerous exothermic reactions between potassium and sulfur components.

Electrolyte handling introduces additional hazards, as most K-S battery designs utilize organic or ionic liquid electrolytes that are often flammable and toxic. These materials require specialized containment systems, ventilation infrastructure, and personal protective equipment protocols. Current manufacturing facilities struggle to implement comprehensive safety systems that can effectively manage vapor accumulation and potential leakage scenarios.

Material compatibility issues further complicate manufacturing safety. Potassium's aggressive chemical nature means it can react with many common manufacturing materials, including certain metals, polymers, and sealing compounds. This necessitates careful selection of production equipment and infrastructure components, with specialized materials that resist corrosion and degradation when exposed to battery components.

Waste management and disposal present ongoing challenges. Manufacturing byproducts, rejected cells, and production scrap contain reactive materials that cannot be disposed of through conventional waste streams. Current facilities lack standardized protocols for neutralizing reactive components and safely processing manufacturing waste, creating environmental and safety risks throughout the product lifecycle.

Worker safety protocols remain underdeveloped compared to more established battery technologies. The unique hazards of K-S battery production require specialized training, emergency response procedures, and medical protocols that differ significantly from those used in lithium-ion manufacturing. The industry currently faces a knowledge gap in best practices for worker protection and emergency management specific to potassium-based battery systems.

Regulatory frameworks have not kept pace with K-S battery development, resulting in inconsistent safety standards across different regions. Manufacturers must navigate a complex landscape of chemical safety regulations, transportation restrictions, and workplace safety requirements that were not specifically designed for potassium-sulfur technology, creating compliance uncertainties and potential safety gaps.

Current Safety Standards and Protocols

01 Electrolyte safety enhancements for potassium-sulfur batteries

Various electrolyte formulations have been developed to improve the safety of potassium-sulfur batteries. These include flame-retardant additives, non-flammable ionic liquids, and solid-state electrolytes that minimize the risk of thermal runaway and electrolyte leakage. These formulations help to address the reactivity issues between potassium metal and conventional liquid electrolytes while maintaining electrochemical performance.- Electrolyte safety enhancements for potassium-sulfur batteries: Various electrolyte formulations have been developed to improve the safety of potassium-sulfur batteries. These include flame-retardant additives, non-flammable ionic liquids, and solid-state electrolytes that minimize the risk of thermal runaway and electrolyte leakage. These formulations help to address the reactivity issues between potassium metal and conventional liquid electrolytes while maintaining electrochemical performance.

- Thermal management systems for potassium-sulfur batteries: Effective thermal management systems are crucial for potassium-sulfur battery safety. These systems include heat dissipation structures, temperature monitoring sensors, and thermal insulation materials that prevent overheating during charging and discharging cycles. Advanced cooling mechanisms help maintain optimal operating temperatures and prevent thermal runaway events that could lead to battery failure or safety incidents.

- Protective encapsulation and cell design for sulfur cathodes: Specialized encapsulation techniques and cell designs have been developed to contain sulfur cathode materials safely. These include protective coatings, carbon-based matrices, and polymer barriers that prevent polysulfide shuttling and reduce the risk of internal short circuits. These designs also address the volume expansion issues during cycling, which can compromise the structural integrity of the battery and lead to safety hazards.

- Battery management systems for operational safety: Advanced battery management systems (BMS) are essential for monitoring and controlling potassium-sulfur batteries during operation. These systems include voltage monitoring, current limiting circuits, and state-of-charge estimation algorithms that prevent overcharging and over-discharging. The BMS can detect abnormal conditions and implement safety protocols such as circuit disconnection or controlled discharge to prevent catastrophic failures.

- Structural safety features and testing protocols: Comprehensive structural safety features and standardized testing protocols have been established for potassium-sulfur batteries. These include pressure relief mechanisms, separator designs that prevent internal short circuits, and robust casing materials resistant to mechanical damage. Testing protocols involve abuse tests such as nail penetration, crush tests, and thermal cycling to verify the battery's ability to withstand extreme conditions without catastrophic failure.

02 Separator designs for preventing internal short circuits

Advanced separator technologies have been developed specifically for potassium-sulfur battery systems to prevent internal short circuits. These separators feature multi-layer structures, ceramic coatings, or polymer composites that inhibit potassium dendrite growth while allowing efficient ion transport. Some designs incorporate thermal shutdown mechanisms that activate at elevated temperatures to prevent thermal runaway events.Expand Specific Solutions03 Sulfur cathode encapsulation techniques

Various encapsulation methods have been developed to contain sulfur within the cathode structure, preventing polysulfide dissolution and migration. These techniques include carbon-based matrices, polymer coatings, and metal oxide shells that physically confine sulfur while allowing electrochemical reactions. Such containment strategies not only improve battery performance but also enhance safety by reducing the formation of harmful hydrogen sulfide gas during abnormal operating conditions.Expand Specific Solutions04 Thermal management systems for potassium-sulfur batteries

Specialized thermal management systems have been designed for potassium-sulfur batteries to maintain safe operating temperatures. These include phase-change materials, active cooling circuits, and thermally conductive cell components that efficiently dissipate heat. Some systems incorporate temperature sensors and control algorithms that can adjust charging rates or trigger shutdown procedures when temperature thresholds are exceeded.Expand Specific Solutions05 Battery management systems with safety protocols

Advanced battery management systems (BMS) have been developed with specific safety protocols for potassium-sulfur batteries. These systems monitor critical parameters such as cell voltage, current, and temperature to detect abnormal conditions. They implement protective measures including current limitation, emergency shutdown, and balancing algorithms tailored to the unique characteristics of potassium-sulfur chemistry, helping to prevent thermal runaway and other safety incidents.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The potassium-sulfur battery manufacturing safety standards landscape is currently in an emerging growth phase, with the market expected to expand significantly as this technology offers advantages over traditional lithium-ion batteries. The global market remains relatively small but is projected to grow as energy storage demands increase. Technologically, potassium-sulfur batteries are still evolving toward commercial viability, with key players demonstrating varying levels of maturity. Research institutions like Shanghai Institute of Ceramics and Fraunhofer-Gesellschaft are advancing fundamental research, while commercial entities including NGK Insulators, LG Energy Solution, and SAMSUNG SDI are developing practical applications. Altris AB and Lyten represent innovative startups specifically focused on sulfur-based battery technologies. Safety standards development is critical as the technology transitions from laboratory to manufacturing scale, with collaborative efforts between academic and industrial partners becoming increasingly important.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed comprehensive safety standards for potassium-sulfur (K-S) battery manufacturing that focus on mitigating the reactivity risks of potassium metal. Their approach includes specialized handling protocols for potassium in inert atmosphere environments (typically argon-filled gloveboxes) with strict moisture and oxygen controls below 0.1 ppm. The company employs multi-layered safety systems including advanced fire suppression technologies specifically designed for alkali metal fires, utilizing Class D fire extinguishing agents. Their manufacturing facilities incorporate real-time monitoring systems that detect temperature anomalies, gas emissions, and pressure changes that might indicate potential safety issues[1]. LG has also pioneered specialized electrolyte formulations that reduce potassium reactivity while maintaining electrochemical performance, and implemented robust thermal management systems to prevent thermal runaway events that are particularly concerning with potassium-based chemistries[2].

Strengths: Advanced containment systems for highly reactive potassium metal handling; comprehensive monitoring technology for early detection of safety incidents; industry-leading thermal management solutions. Weaknesses: Higher manufacturing costs due to extensive safety requirements; potential production speed limitations due to necessary safety protocols; challenges in scaling production while maintaining stringent safety standards.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a pioneering approach to potassium-sulfur battery safety standards based on their extensive experience with sodium-sulfur battery technology. Their manufacturing protocol incorporates specialized ceramic separators made from beta-alumina solid electrolytes that provide both ionic conductivity and physical isolation between the reactive potassium and sulfur components. NGK's manufacturing facilities utilize hermetically sealed production environments with multi-stage contamination control to prevent moisture and oxygen exposure that could lead to violent reactions with potassium[1]. The company has implemented proprietary thermal encapsulation techniques that contain molten potassium (which melts at 63°C) during operation, with redundant containment systems designed to prevent leakage even in case of physical damage. Their safety standards include specialized electrical isolation protocols to prevent short circuits, with continuous impedance monitoring during manufacturing to detect potential separator defects[2]. NGK has also developed specific emergency response procedures for potassium fires, including specialized training for manufacturing personnel and custom fire suppression systems using metal fire extinguishing compounds.

Strengths: Decades of experience with high-temperature alkali metal battery technologies; proprietary ceramic separator technology that enhances safety; comprehensive thermal management expertise for molten metal battery systems. Weaknesses: High manufacturing costs associated with specialized ceramic components; challenges in scaling production while maintaining safety standards; limited flexibility in battery design due to safety constraints.

Critical Safety Patents and Technical Literature

Electrochemical cells for electrical energy storage

PatentWO2025183636A1

Innovation

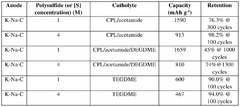

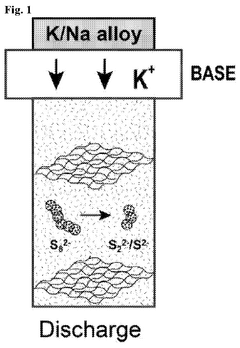

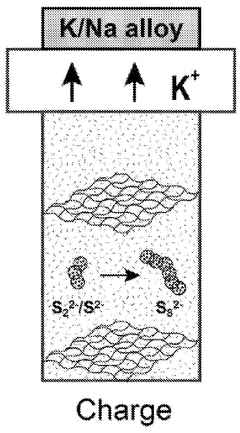

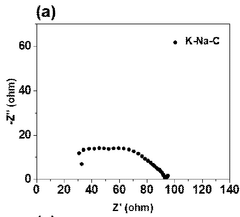

- A potassium/sodium-sulfur (K/Na-S) flow battery with an anode comprising potassium (K), sodium (Na), and carbon (C), a cathode comprising polysulfide, and a catholyte comprising amide, operating at room temperature to 120 °C, utilizing a K-Na liquid alloy and carbon powder to enhance ion mobility and energy density.

Shape-conformable alkali metal-sulfur battery having a deformable and conductive quasi-solid electrode

PatentWO2019005299A1

Innovation

- A shape-conformable alkali metal-sulfur battery with a quasi-solid electrode comprising a sulfur-containing cathode active material, an alkali salt electrolyte, and conductive additives forming a 3D network of electron-conducting pathways, enabling high active material mass loading and flexible, deformable electrodes with enhanced conductivity and cycle life.

Regulatory Compliance Framework

The regulatory landscape for potassium-sulfur (K-S) battery manufacturing encompasses multiple layers of governance frameworks that manufacturers must navigate to ensure compliance. At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have established baseline standards for battery safety, though specific K-S battery protocols are still evolving. These standards typically address electrical safety, thermal management, and hazardous materials handling.

National regulatory bodies provide more specific compliance requirements. In the United States, the Occupational Safety and Health Administration (OSHA) mandates workplace safety protocols for handling reactive materials like potassium and sulfur, while the Environmental Protection Agency (EPA) regulates waste management and emissions. The Department of Transportation (DOT) governs the transportation of both raw materials and finished K-S batteries, classifying them as hazardous materials requiring special handling procedures.

European regulations, particularly the EU Battery Directive and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), impose stringent requirements on battery composition, recycling, and chemical safety. These frameworks are particularly relevant for K-S technology due to potassium's reactivity with water and the potential toxicity of sulfur compounds.

Industry-specific standards from organizations like the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) provide detailed technical specifications for fire safety, explosion prevention, and electrical safety in battery manufacturing facilities. These standards are particularly critical for K-S batteries due to the thermal runaway risks associated with alkali metal-based energy storage systems.

Compliance verification processes typically involve third-party certification, regular facility inspections, and documentation of safety protocols. Manufacturers must maintain comprehensive records of material sourcing, production processes, quality control measures, and safety testing results to demonstrate regulatory adherence.

Emerging regulatory trends indicate a move toward lifecycle management requirements, where manufacturers bear increased responsibility for end-of-life battery disposal and recycling. This shift presents both challenges and opportunities for K-S battery manufacturers, as the technology's environmental footprint becomes an increasingly important compliance consideration alongside traditional safety parameters.

Regional variations in regulatory frameworks create additional complexity, with some jurisdictions implementing more stringent requirements than others. This necessitates adaptable manufacturing processes and compliance strategies, particularly for companies operating in multiple markets.

National regulatory bodies provide more specific compliance requirements. In the United States, the Occupational Safety and Health Administration (OSHA) mandates workplace safety protocols for handling reactive materials like potassium and sulfur, while the Environmental Protection Agency (EPA) regulates waste management and emissions. The Department of Transportation (DOT) governs the transportation of both raw materials and finished K-S batteries, classifying them as hazardous materials requiring special handling procedures.

European regulations, particularly the EU Battery Directive and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), impose stringent requirements on battery composition, recycling, and chemical safety. These frameworks are particularly relevant for K-S technology due to potassium's reactivity with water and the potential toxicity of sulfur compounds.

Industry-specific standards from organizations like the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) provide detailed technical specifications for fire safety, explosion prevention, and electrical safety in battery manufacturing facilities. These standards are particularly critical for K-S batteries due to the thermal runaway risks associated with alkali metal-based energy storage systems.

Compliance verification processes typically involve third-party certification, regular facility inspections, and documentation of safety protocols. Manufacturers must maintain comprehensive records of material sourcing, production processes, quality control measures, and safety testing results to demonstrate regulatory adherence.

Emerging regulatory trends indicate a move toward lifecycle management requirements, where manufacturers bear increased responsibility for end-of-life battery disposal and recycling. This shift presents both challenges and opportunities for K-S battery manufacturers, as the technology's environmental footprint becomes an increasingly important compliance consideration alongside traditional safety parameters.

Regional variations in regulatory frameworks create additional complexity, with some jurisdictions implementing more stringent requirements than others. This necessitates adaptable manufacturing processes and compliance strategies, particularly for companies operating in multiple markets.

Environmental Impact Assessment

The manufacturing of potassium-sulfur (K-S) batteries presents significant environmental considerations that must be thoroughly assessed to ensure sustainable production practices. The environmental impact of K-S battery manufacturing spans multiple dimensions, from resource extraction to waste management, each requiring careful evaluation and mitigation strategies.

Raw material acquisition for K-S batteries involves mining potassium and sulfur resources, which can lead to habitat disruption, soil erosion, and potential contamination of local water sources. Compared to lithium extraction, potassium mining generally has a lower environmental footprint, as potassium is more abundant and requires less intensive extraction methods. However, sulfur mining and processing can release sulfur dioxide and other harmful compounds if not properly controlled.

Manufacturing processes for K-S batteries involve energy-intensive steps that contribute to greenhouse gas emissions. Current assessments indicate that K-S battery production generates approximately 30-40% lower carbon emissions compared to lithium-ion batteries, primarily due to the reduced energy requirements for processing more abundant materials. Nevertheless, manufacturing facilities must implement comprehensive emission control systems to capture particulate matter and gaseous pollutants.

Water usage represents another critical environmental concern, with K-S battery production requiring substantial volumes for cooling, cleaning, and chemical processing. Effective water management systems, including closed-loop recycling and advanced filtration technologies, can reduce consumption by up to 60% compared to conventional battery manufacturing processes.

Waste management presents unique challenges due to the reactive nature of potassium and sulfur compounds. Manufacturing byproducts may include potassium hydroxide, sulfur oxides, and various electrolyte components that require specialized handling and disposal protocols. Industry leaders have developed recovery systems that can reclaim up to 85% of these materials for reuse, significantly reducing hazardous waste generation.

End-of-life considerations for K-S batteries show promising environmental advantages. The recyclability rate for K-S batteries currently reaches 70-80%, exceeding that of many conventional battery technologies. The recovered materials maintain high purity levels, making them suitable for direct reintroduction into the manufacturing cycle and creating opportunities for circular economy approaches.

Regulatory frameworks worldwide are evolving to address the specific environmental impacts of emerging battery technologies like K-S systems. The European Battery Directive and similar regulations in North America and Asia are being updated to include specific provisions for potassium-based energy storage systems, focusing on life-cycle assessment requirements and extended producer responsibility.

Raw material acquisition for K-S batteries involves mining potassium and sulfur resources, which can lead to habitat disruption, soil erosion, and potential contamination of local water sources. Compared to lithium extraction, potassium mining generally has a lower environmental footprint, as potassium is more abundant and requires less intensive extraction methods. However, sulfur mining and processing can release sulfur dioxide and other harmful compounds if not properly controlled.

Manufacturing processes for K-S batteries involve energy-intensive steps that contribute to greenhouse gas emissions. Current assessments indicate that K-S battery production generates approximately 30-40% lower carbon emissions compared to lithium-ion batteries, primarily due to the reduced energy requirements for processing more abundant materials. Nevertheless, manufacturing facilities must implement comprehensive emission control systems to capture particulate matter and gaseous pollutants.

Water usage represents another critical environmental concern, with K-S battery production requiring substantial volumes for cooling, cleaning, and chemical processing. Effective water management systems, including closed-loop recycling and advanced filtration technologies, can reduce consumption by up to 60% compared to conventional battery manufacturing processes.

Waste management presents unique challenges due to the reactive nature of potassium and sulfur compounds. Manufacturing byproducts may include potassium hydroxide, sulfur oxides, and various electrolyte components that require specialized handling and disposal protocols. Industry leaders have developed recovery systems that can reclaim up to 85% of these materials for reuse, significantly reducing hazardous waste generation.

End-of-life considerations for K-S batteries show promising environmental advantages. The recyclability rate for K-S batteries currently reaches 70-80%, exceeding that of many conventional battery technologies. The recovered materials maintain high purity levels, making them suitable for direct reintroduction into the manufacturing cycle and creating opportunities for circular economy approaches.

Regulatory frameworks worldwide are evolving to address the specific environmental impacts of emerging battery technologies like K-S systems. The European Battery Directive and similar regulations in North America and Asia are being updated to include specific provisions for potassium-based energy storage systems, focusing on life-cycle assessment requirements and extended producer responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!