Tie back snap

a safety hook and back snap technology, applied in the direction of eye fasteners, hook fasteners, fastening means, etc., can solve the problems of double action, single locking snaps that cannot work for this type of application, and the actual fall path and restraint conditions are rather unpredictable, so as to reduce the applied gate load, prevent rollout (accidental disengagement), and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]While the invention will be described and disclosed here in connection with certain preferred embodiments, the description is not intended to limit the invention to the specific embodiments shown and described here, but rather the invention is intended to cover all alternative embodiments and modifications that fall within the spirit,and scope of the invention as defined by the claims included herein as well as any equivalents of the disclosed and claimed invention.

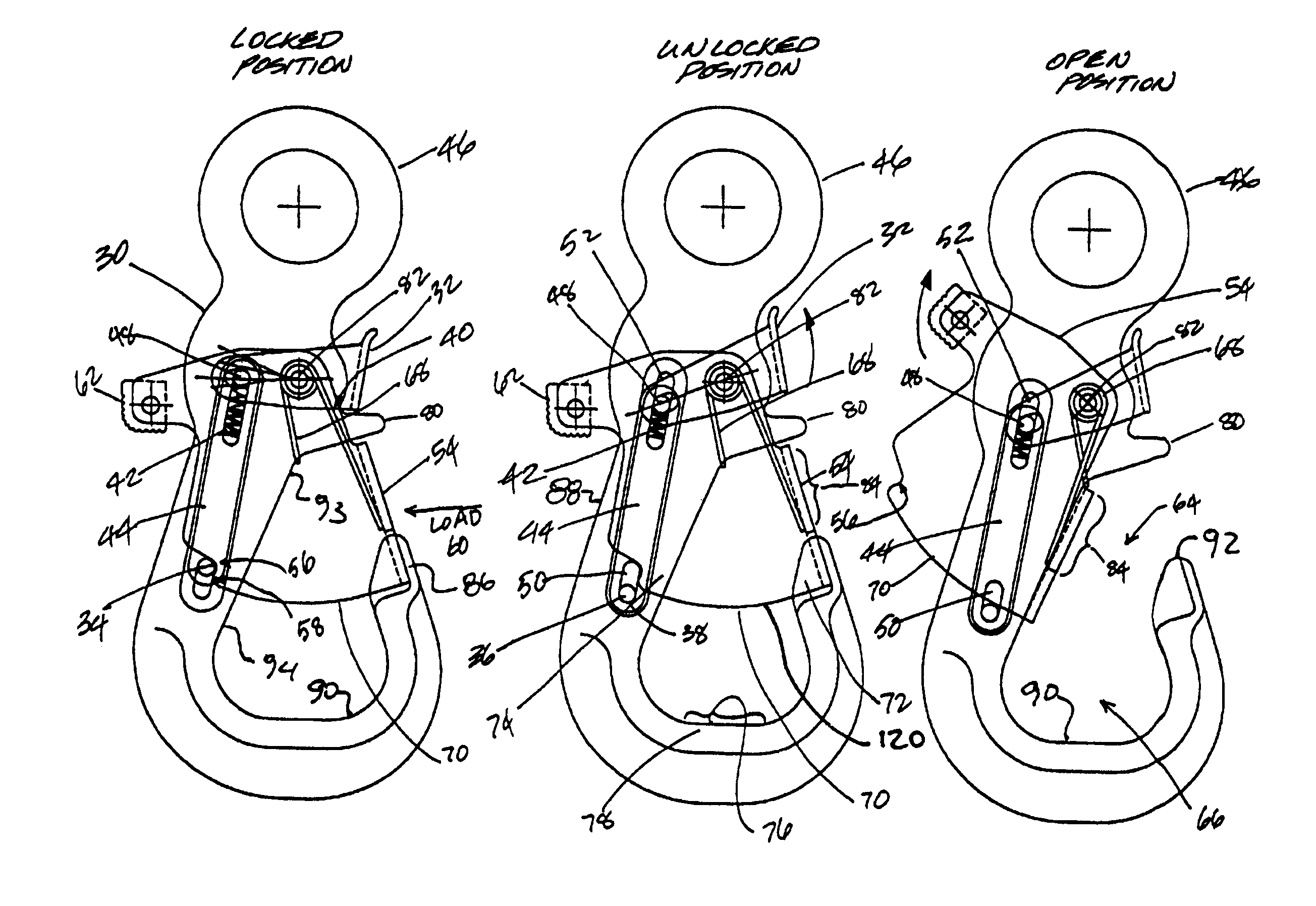

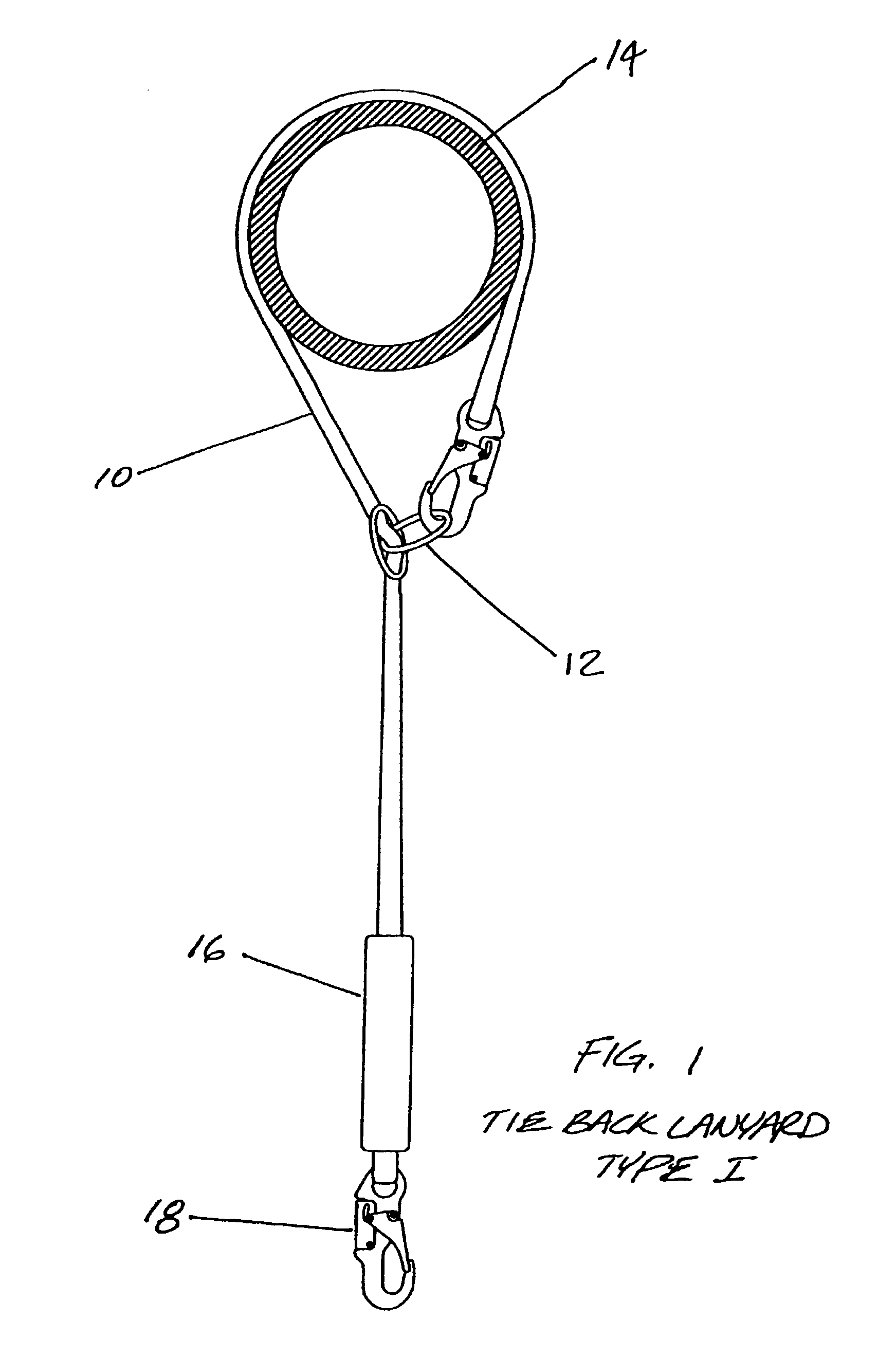

[0041]Turning now to FIGS. 1 through 3 illustrates the tie back snap geometry, use, and assembly according to the preferred embodiment of this invention. Referring to FIG. 1 the tie back lanyard Type 1(10) is shown attached to the tie back ring (12). The beam to which it is attached is a round pipe (14). The shock absorbing tie back lanyard (10) is shown with an integral shock absorber (16) and harness snap (18).

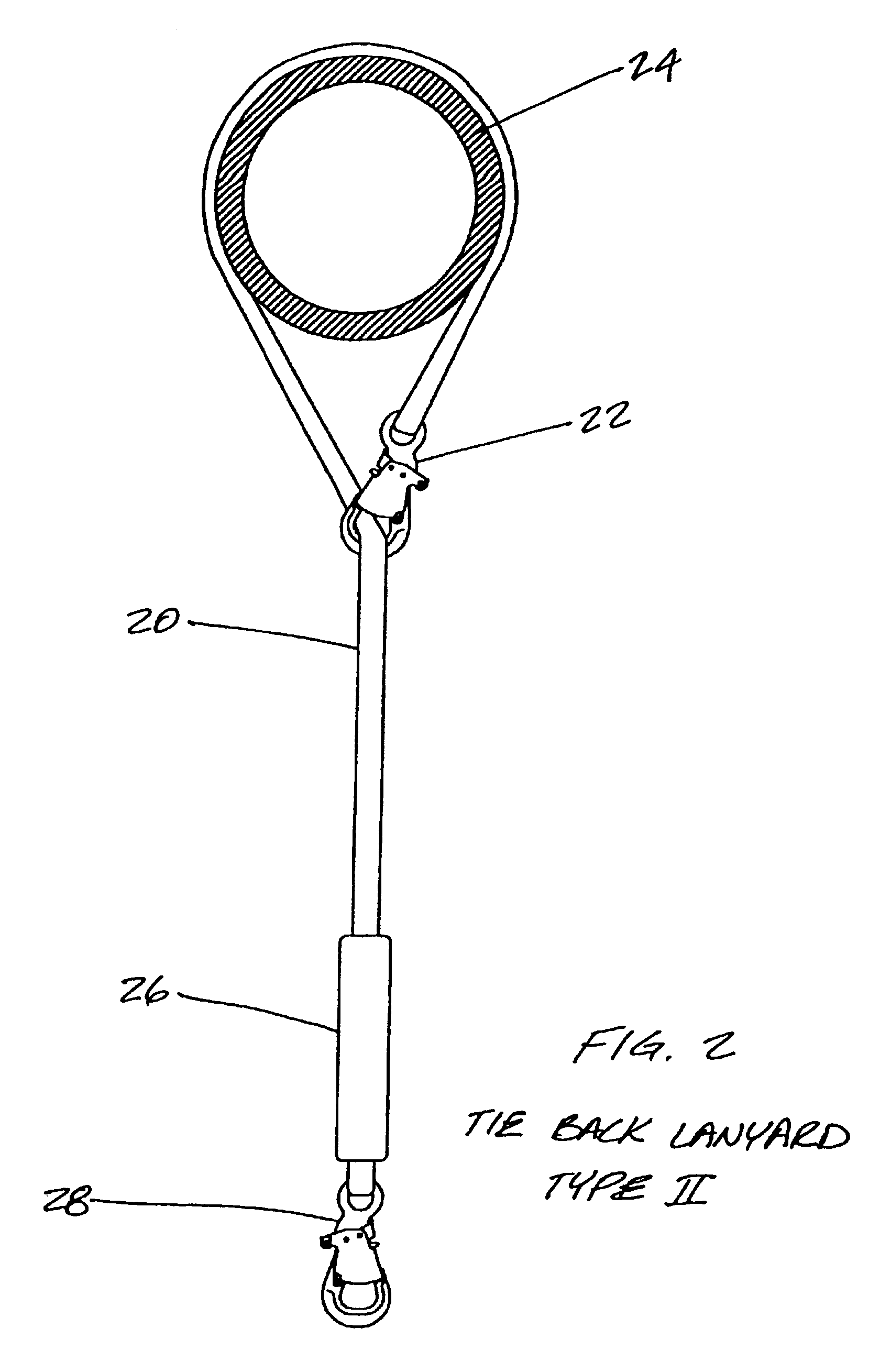

[0042]FIG. 2 shows the tie back lanyard Type II (20) with an integral tie back snap (22) positioned aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com