Throttle valve control device for an internal combustion engine

a control device and internal combustion engine technology, applied in the direction of electric control, ignition automatic control, speed sensing governors, etc., can solve the problems of automobiles not being able to travel at automobiles cannot be able to continue to travel at a desirable speed, and automobiles cannot be able to achieve the speed of 30 km/h, reducing torque, and reducing electrical load on the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0052]Referring first to FIGS. 7 and 8, a basic construction and its operational principle of the present invention will be explained.

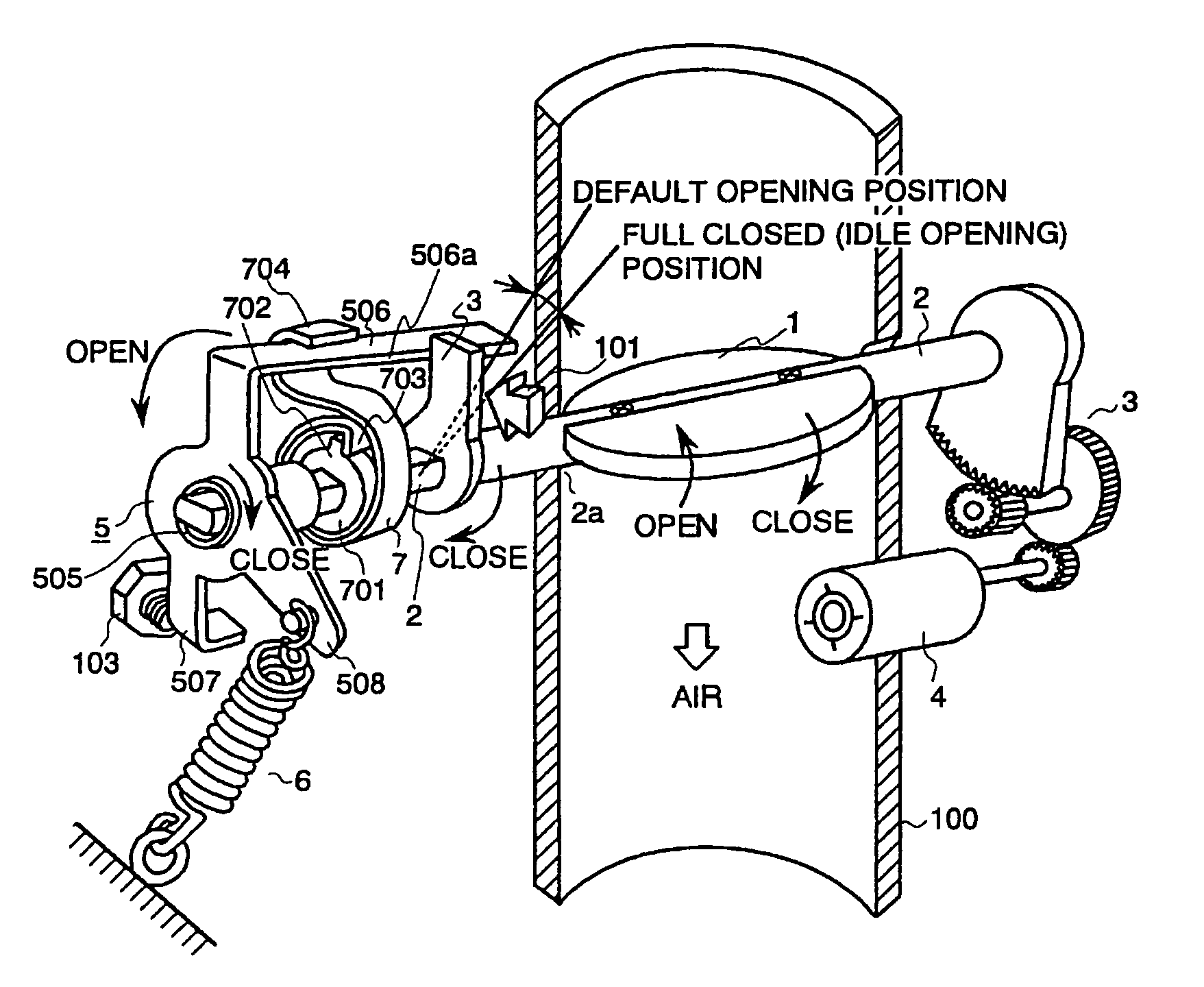

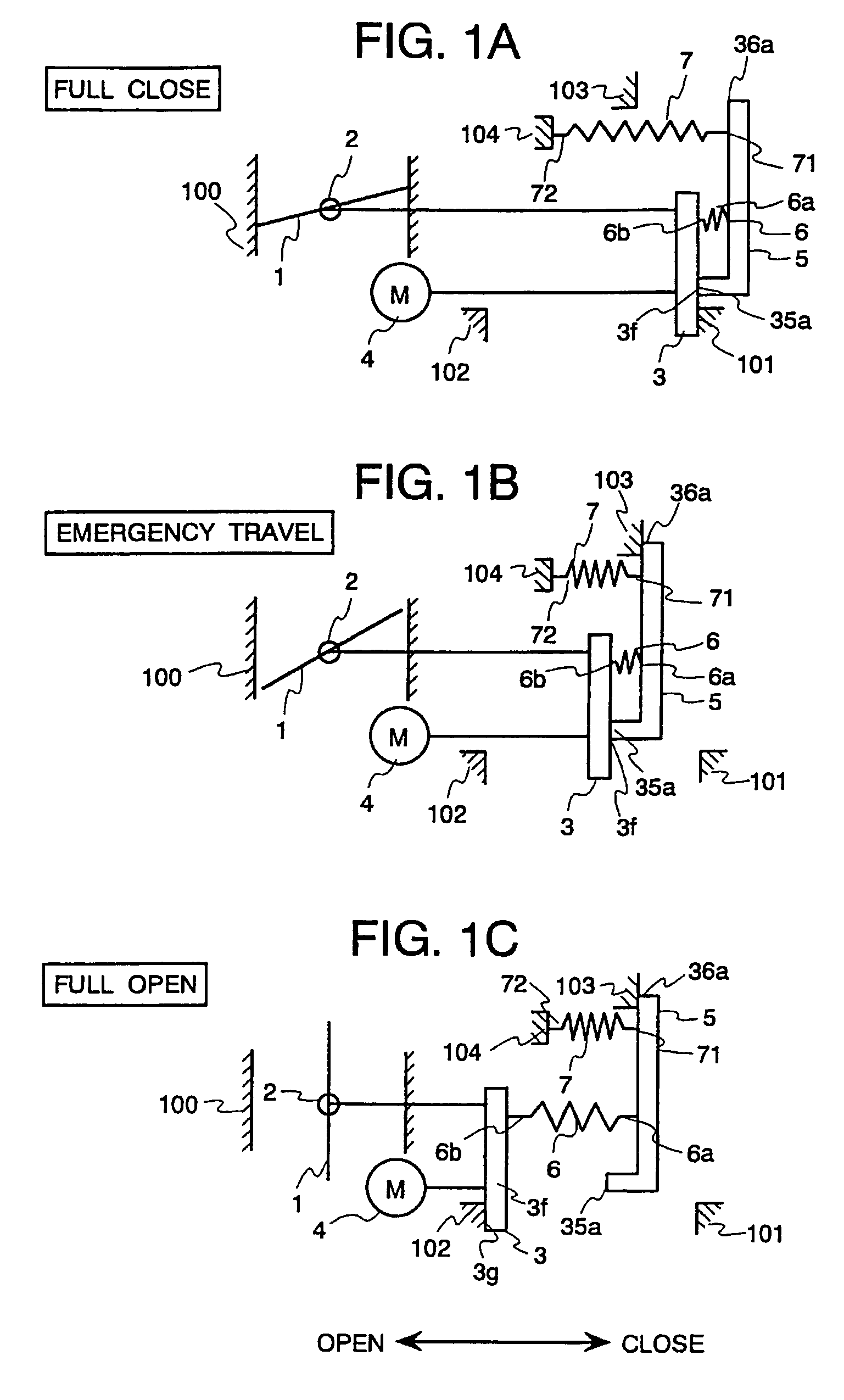

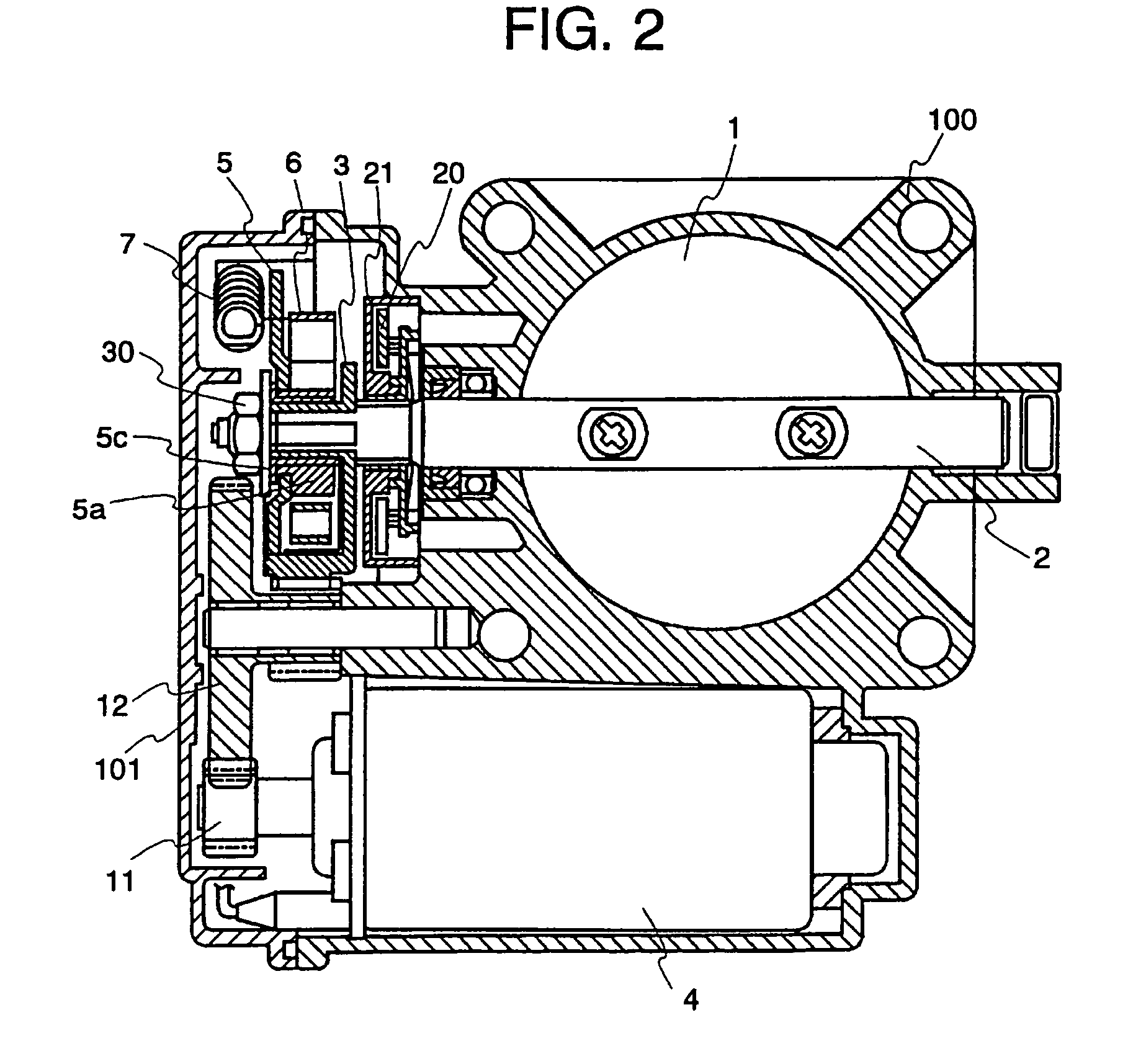

[0053]In FIG. 7, air flowing through intake pipe 100 is adjusted by the throttle valve 1 which is fixed to the throttle valve shaft 2. Reduction gears 3 are attached at the end of the throttle shaft 2. Rotating torque of the throttle valve motor 4 is transmitted to the throttle valve 1 through the gears 3, whereby the opening of the throttle valve 1 can be adjusted.

[0054]The rotation of the motor 4 is controlled in proportion to the depression amount of the acceleration pedal and therefore the opening of the throttle valve 1 is adjusted by the acceleration pedal.

[0055]Coupling lever 5 is supported by the throttle shaft 2, but can rotate independently therefrom. The lever 5 is energized toward the default stopper 103 by the default spring 7. The default spring 7 may be of an extension type or a compression type. If the throttle valve motor 4 is not fed...

second embodiment

[0089]Referring first to FIG. 9, however, description will be made of the principle of the

[0090]In FIG. 9, the throttle valve 1 is attached to the throttle valve shaft 2 which is rotated by the throttle valve motor 4 clockwise or counterclockwise through the reduction gear 3 in the same manner as in FIG. 7. The coupling lever 5 is arranged rotatably in relation to the throttle shaft 2 which is also the same as in FIG. 7. The following are the differences from FIG. 7:[0091](1) the throttle valve 1 is closed at the default position by the return spring 6 through the coupling lever 5; and[0092](2) the default spring 7 is provided between the throttle valve 1 and the coupling lever 5.[0093]The above structural differences cause the following operational differences:[0094](a) from the default position to the full close stopper, the throttle shaft 2 rotates independently, separated from the coupling lever 5. At this time, force of the default spring 7 acts directly on the throttle shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com