Fastener delivery tube

a technology of fastener and delivery tube, which is applied in the direction of conveyor parts, applications, transportation and packaging, etc., to achieve the effect of increasing the free space between the bells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

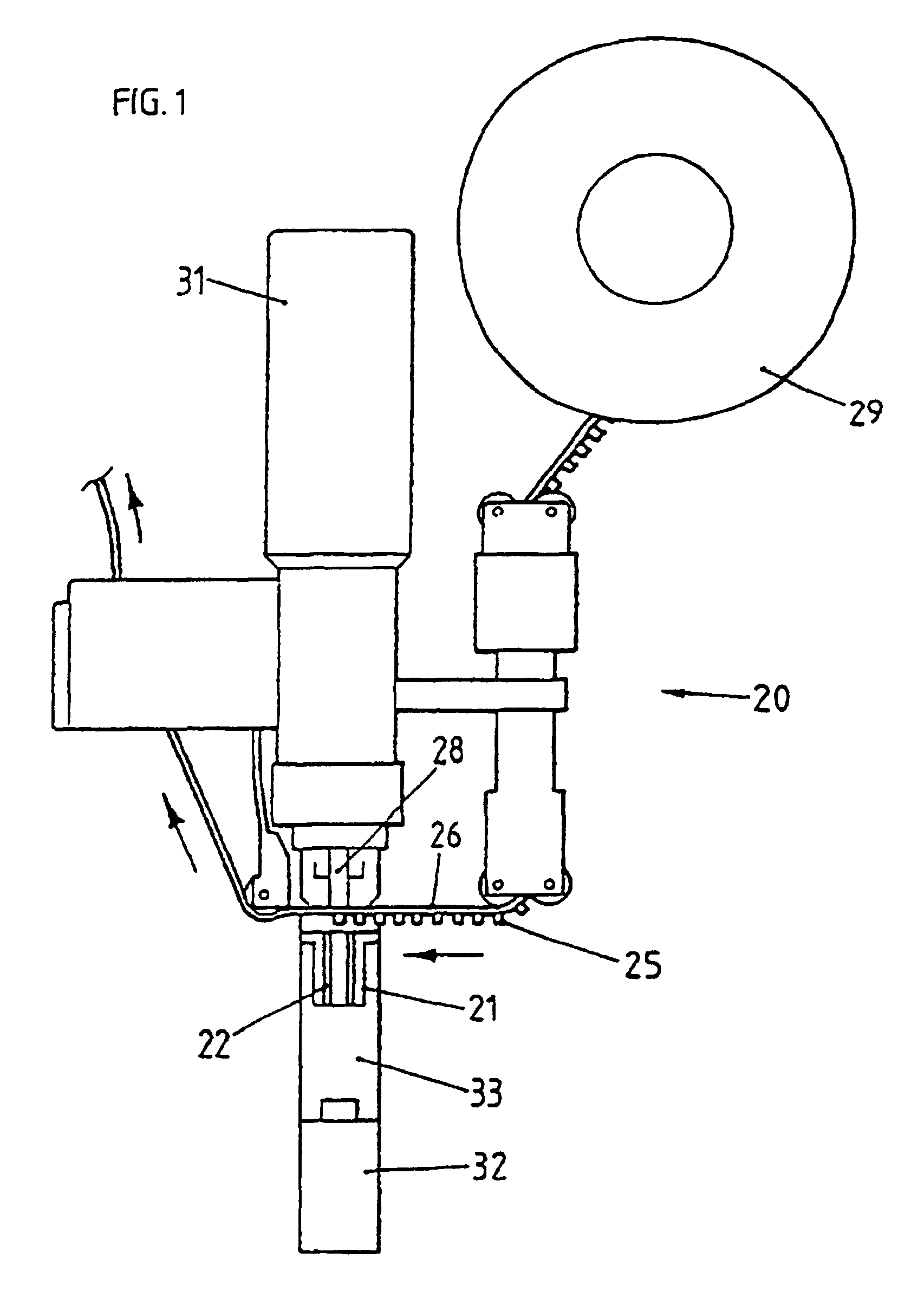

[0053]Referring to the drawings, and in particular FIG. 1, a fastener applicator 20 has a fluid-actuated ram 31, with a movable piston or plunger driving head 28 for contacting the head of an individual fastener 25 and driving the fastener 25 into a workpiece (not shown) mounted in the throat 33 of a C-frame 32.

[0054]For repetitive operation, fasteners 25 are transported to the driving plunger 28 as a linear succession in a carder tape 26, typically of flexible synthetic plastics, from a reservoir or supply spool or cartridge 29 to a position underneath the driving plunger 28.

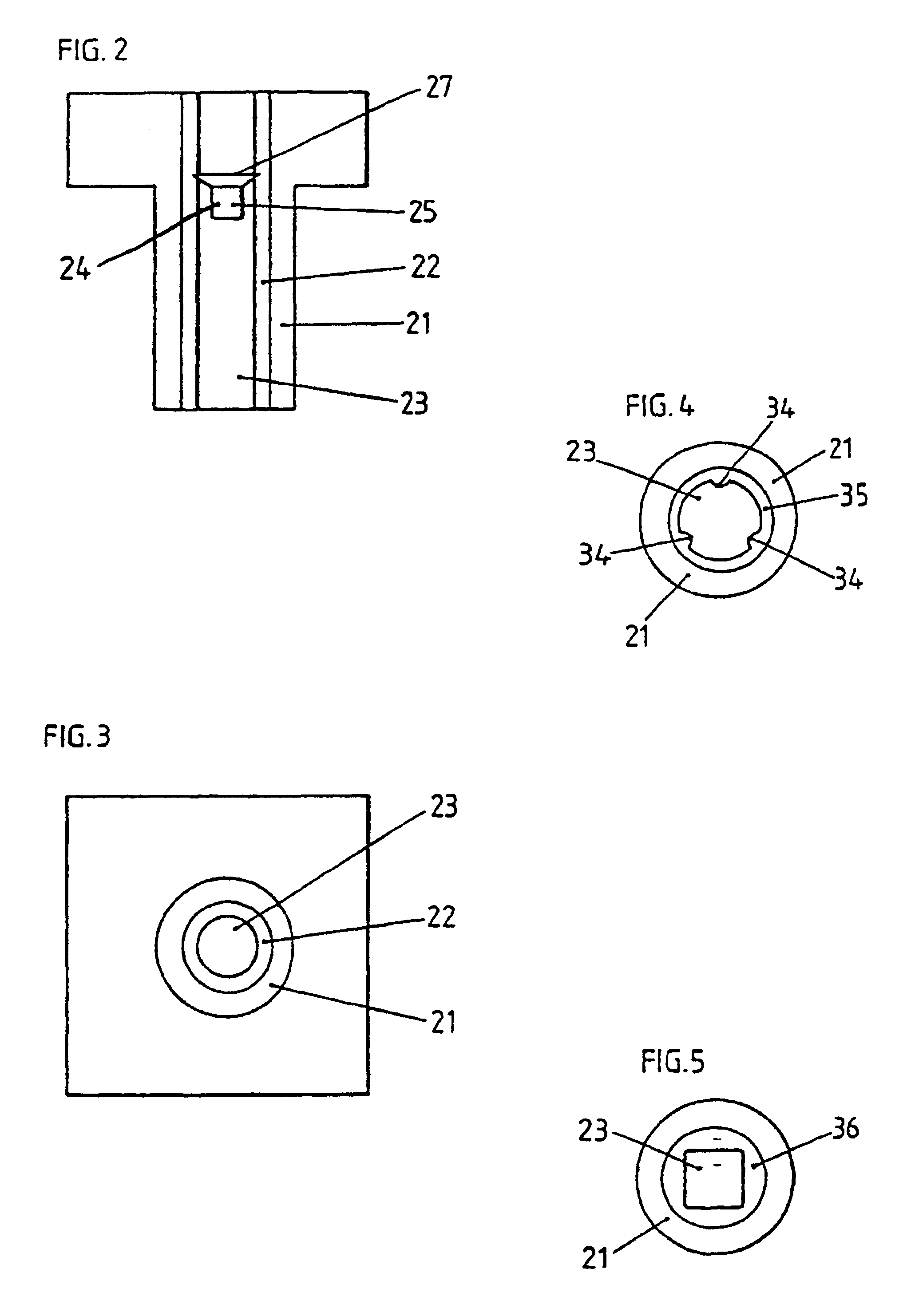

[0055]In order to gain access to a workpiece in positions where space is restricted, it is often necessary to release a fastener 25 from the carrier tape at a point remote from the workpiece and to use a delivery tube 21 to convey the fastener 25 to the point of application.

[0056]It is with such a delivery tube 21—and the interaction of its internal passage with the external profile of a fastener 25—that the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com