Composite Hose with a Corrugated Metal Tube and Method for Making the Same

a technology of corrugated metal and composite hoses, which is applied in the direction of flexible pipes, mechanical equipment, pipes, etc., can solve the problems of fatigue crack, fatigue crack of corrugated metal tubes, lowering durability, etc., and achieves the effect of reliable restraining effect, easy fatigue-broken, and reduced non-uniform durability of composite hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

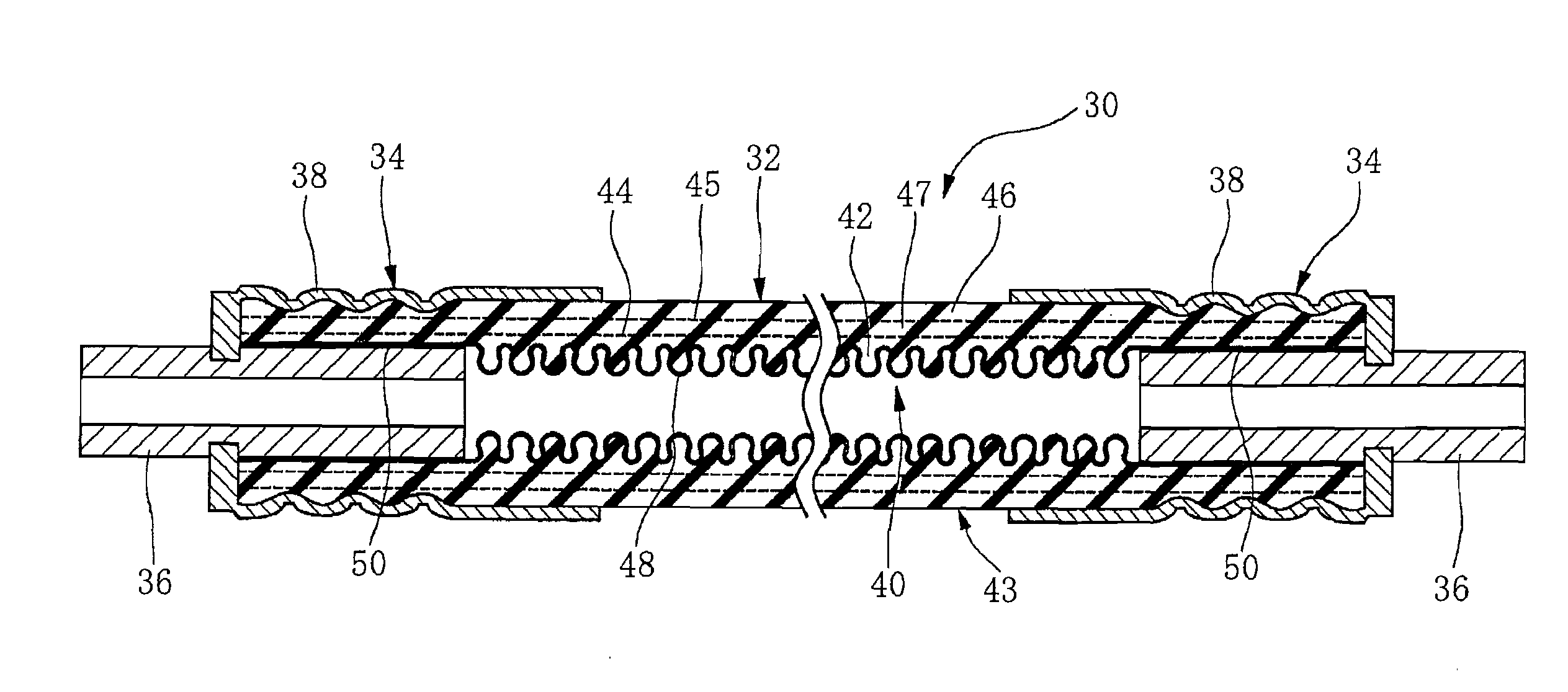

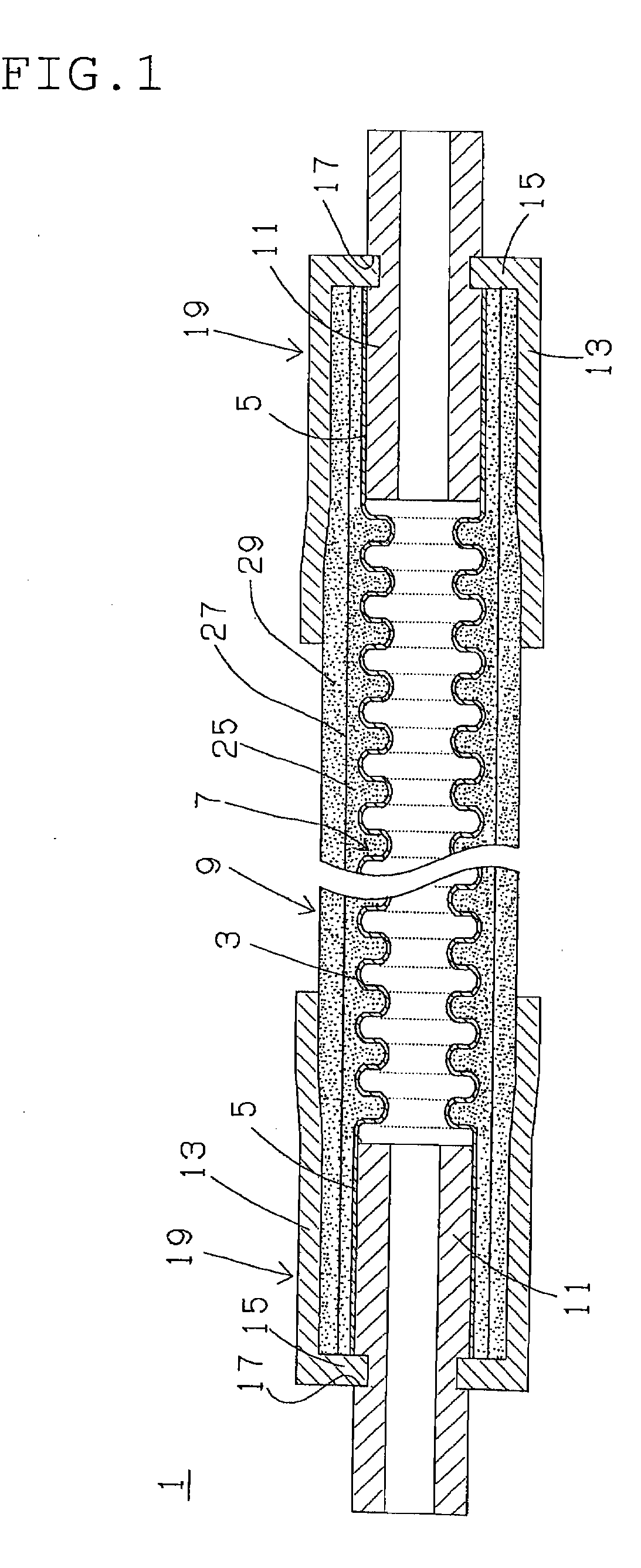

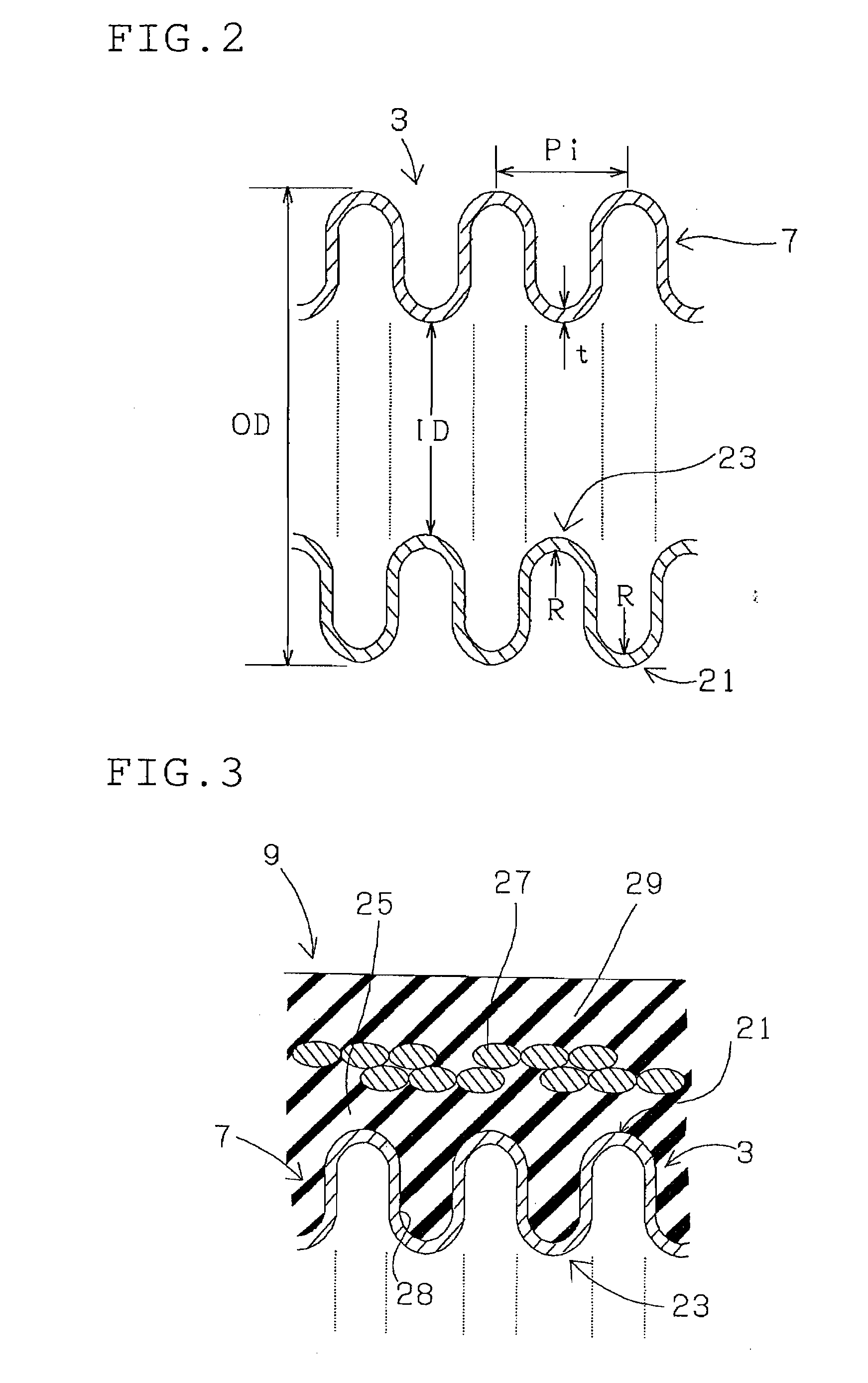

[0047]FIG. 1 shows a first composite hose with a corrugated metal tube (wherein a corrugate metal tube is not plastically deformed yet) according to the present invention. A first composite hose with a corrugated metal tube 1 (hereinafter referred to just as a first hose 1) comprises a corrugated metal tube 7 as an inner peripheral portion, an outer peripheral portion 9 which is provided on an outer side of the corrugated metal tube 7, a metal insert fitting 11 which is shaped a pipe. The corrugated metal tube 7 integrally has a corrugated portion 3 which is formed with corrugation hills and corrugation valleys and straight-wall portions 5, 5 which are formed on opposite ends of the corrugated portion 3. The insert fitting 11 is inserted in each of the straight-wall portions 5, 5 of the corrugated metal tube 7. The first hose 1 further comprises sleeve-like socket fittings 19, 19. Each socket fitting 19 integrally has a tubular portion 13 and an inwardly-directed flange 15 which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com