Low profile inductive component

a technology of inductive components and low profile, which is applied in the field of low profile surface mountable inductive components, can solve the problems of low profile components, limited technology, and more powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

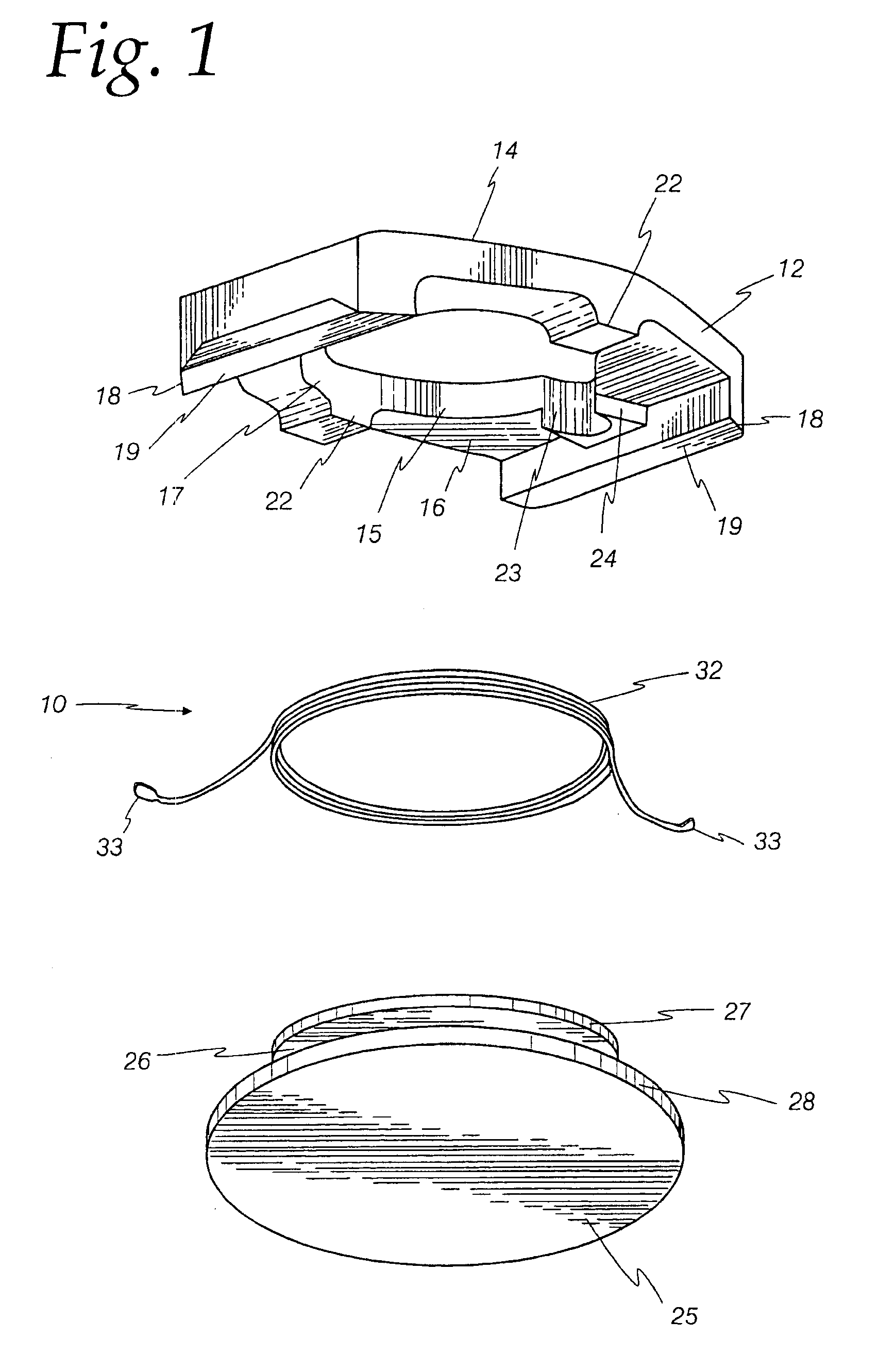

[0017]Turning first to FIGS. 1 and 2, a low profile inductive component in accordance with the invention for mounting above the printed circuit board (PCB) is shown generally at reference numeral 10. For convenience, the inductive component is described as it would be positioned on the upper surface of a PCB.

[0018]In FIGS. 1 and 2, the low profile inductive component 10 includes a low profile body 12 made of an insulating material, such as a non-conductive plastic or ceramic. The body 12 has a polygonal shape, such as a hexagon, and is defined by a smooth planer top 14 and a bottom 16. The body 12 defines an aperture 15 passing directly through the center of the top 14 and the bottom 16, and having an inner wall 17.

[0019]A pair of legs 18 extend downward from opposite ends of the body 12. Soldering pads 19 are located at the bottom of the legs 18, which are made of a conductive material, such as metal, for electrically and mechanically attaching the low profile inductive component 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com