Devices using silicone pressure sensitive adhesives containing organic wax

a technology of silicone and organic wax, which is applied in the direction of pharmaceutical delivery mechanisms, dressings, bands, etc., can solve the problems of increasing profits and cost savings, and achieve the effects of reducing the dynamic viscosity of adhesives, less viscosity, and improving adhesive coatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

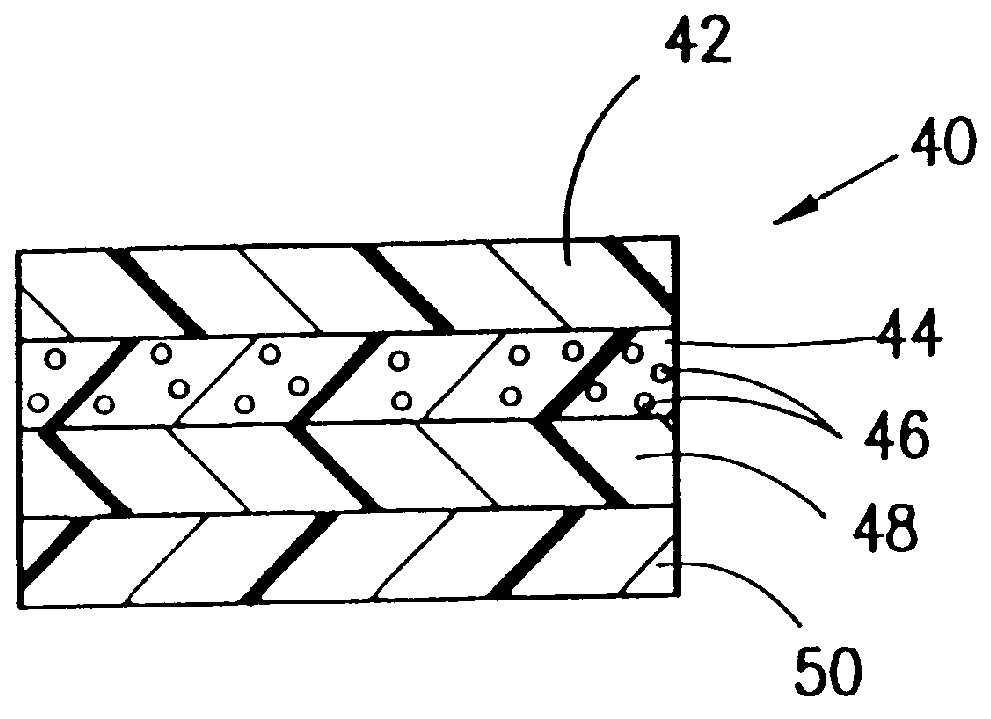

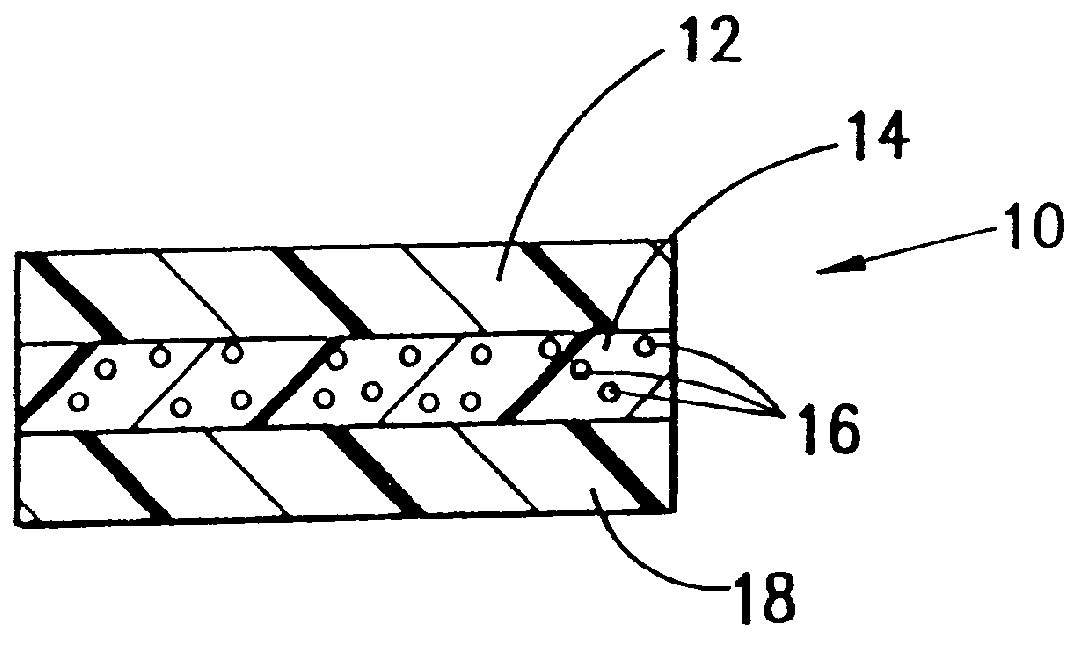

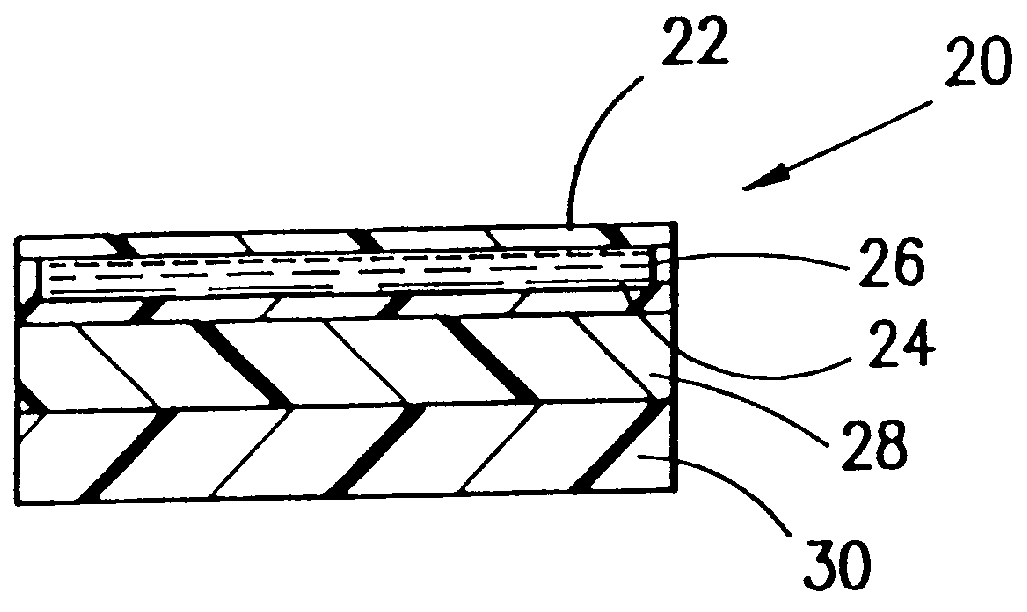

Image

Examples

example 1

Adhesive formulations combining PSA I and amounts of organic waxes were prepared as set forth in Tables 1A and 1B. As shown in Table 1A, these adhesive preparations were evaluated for physical properties of tack, release, adhesion and shear. Tack values ranged between 86 and 341 gm / cm.sup.2, and all were well within the acceptable range of 50 to 800 gm / cm.sup.2. Release values ranged between 1.6 and 9.3 gm / cm. All samples were within the acceptable range of less than or equal to 50 gm / cm. Adhesion values for our samples ranged between 228 and 729 gm / cm. These values were all within the acceptable range of 100-2000 gm / cm. Shear values ranged from 12.06 to 16.06 Kg / 6.25 cm.sup.2 and were within the acceptable range of 4 to 20 kg / 6.25 cm.sup.2.

As shown in Table 1B, the Rheological properties of Elastic Modulus (G') and Dynamic Viscosity (n*) were evaluated for formulations of PSA I containing various organic waxes. Particularly relevant are the values measured at temperatures utilized ...

example 2

Adhesive formulations combining Control PSA II with varying amounts of organic waxes were prepared as set forth in Tables 2A and 2B. As shown in Table 2A, these adhesive preparations were evaluated for physical properties of tack, release, adhesion and shear. Tack values for all samples were outside the acceptable range of 50 to 2000 gm / cm.sup.2. Release values ranged between 0 and 0.8 gm / cm. All samples were within the acceptable release value range of less than or equal to 50 gm / cm. All samples were within the acceptable range for adhesion values of 100-2000 gm / cm.sup.2. All samples had shear values within the acceptable range of 4 to 20 kg / 6.25 cm.sup.2.

As shown in Table 2B, the Rheological properties of Elastic Modulus (G') and Dynamic Viscosity (n*) were evaluated for the various adhesive formulations. Particularly relevant are the values measured at temperatures equal to or below 200.degree. C. Elastic Modulus Values (G') equal to or less than 45,000 dynes / cm.sup.2 at 200.degr...

example 3

Now we look at adhesive formulations combining Control PSA III with varying amounts of organic waxes which were prepared as set forth in Tables 3A and 3B. As shown in Table 3A, these adhesive preparations were evaluated for physical properties of tack, release, adhesion and shear. Tack values ranged between 97 and 371 gm / cm.sup.2 were well within the acceptable range of 50 to 800 gm / cm.sup.2. Release values ranged between 1.2 and 16.1 gm / cm. All samples were within the acceptable range of less than or equal to 50 gm / cm. Adhesion values ranged between 134 and 683 gm / cm. All samples were within the acceptable adhesion range of 100-2000 gm / cm. Shear values ranged from 12.81 to 15.91 kg / 6.25 cm.sup.2 and were within the acceptable range of 4 to 20 kg / 6.25 cm.sup.2.

As shown in Table 3B, the Rheological properties of Elastic Modulus (G') and Dynamic Viscosity (n*) were evaluated for the various adhesive formulations. Particularly relevant are the values measured at temperatures equal to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com