Method and apparatus for automatically segmenting animal carcasses

a technology of animal carcasses and automatic segmentation, which is applied in the field of meat processing, can solve the problems of inconvenient and laborious primary cutting operation, inability to consistently produce the most effective yield of butchers, and no automated butchering system exhibits more accuracy than butchers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

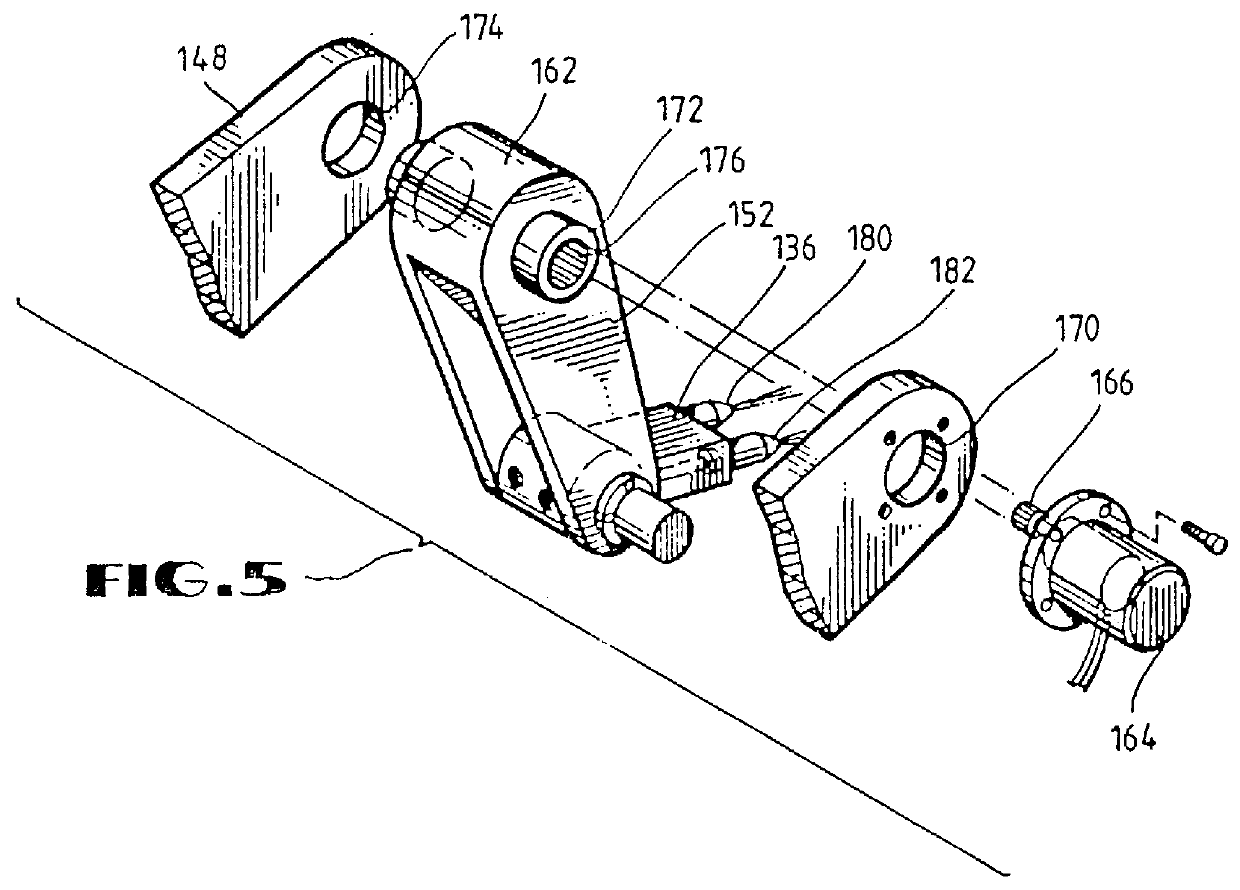

Image

Examples

Embodiment Construction

Turning now to the drawings and referring initially to FIG. 1A, an apparatus for automatically segmenting animal carcasses is illustrated and generally designated by a reference numeral 10. Although the following description of the operation of the apparatus 10 will assume that the apparatus 10 is segmenting a cattle carcass 11, the apparatus 10 is also useful for processing other types of animals, such as pigs and lambs. Once an animal has been killed, the animal is preferably hung on an overhead rail conveyor, and its hide and entrails are removed. After the animal has been stripped and eviscerated, the carcass is typically chilled or frozen to minimize fluid loss during subsequent processing. After chilling, the rail conveyor 12 delivers the carcass 11 of the animal to a mounting station 14.

At the mounting station 14, a laborer removes the animal carcass from the overhead conveyor 12 and places the animal carcass on a mounting vehicle 16. The mounting vehicle 16, which forms a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com