Valve pile tip structure device of cast-in-place X-shaped concrete pile and using method thereof

A technology of valve pile tips and concrete piles, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., and can solve the problems that prefabricated spud boots cannot be reused, spud boots can only move downwards, and can only move downwards. , to achieve the effect of avoiding heavy manual labor, good integrity and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

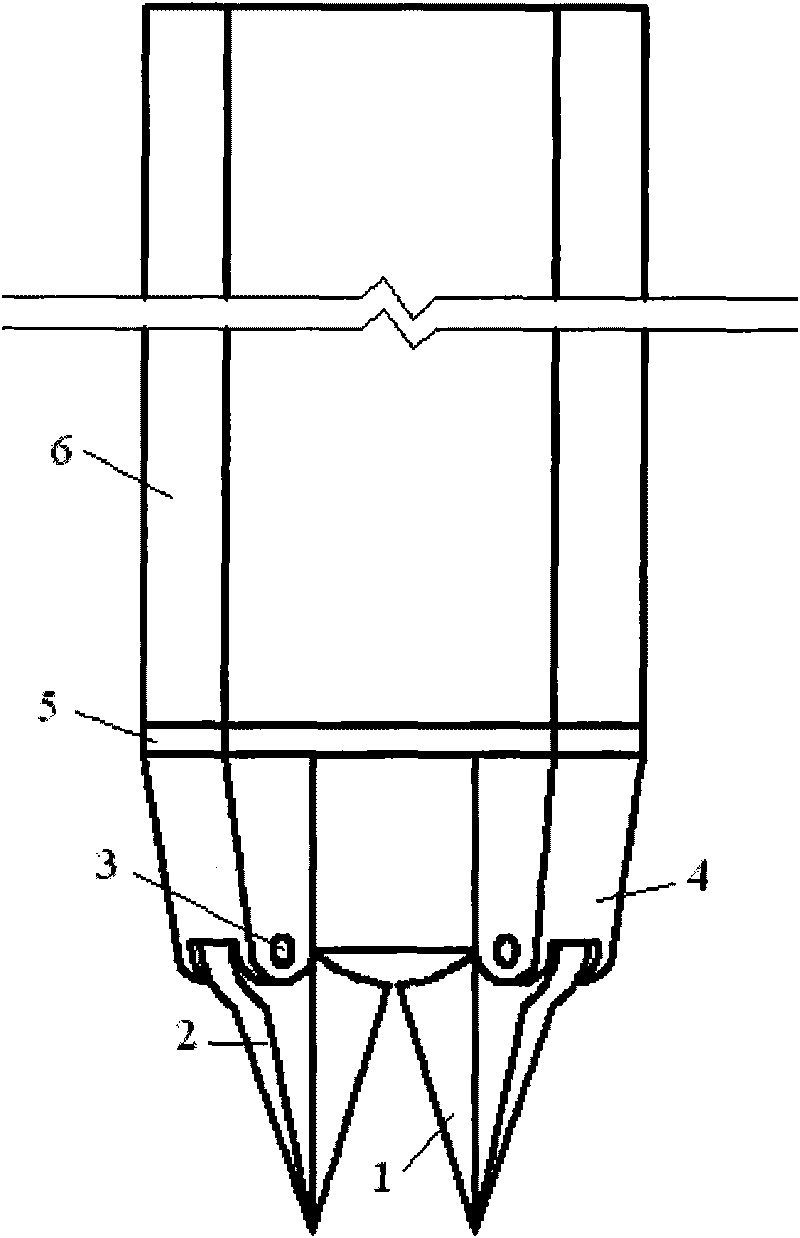

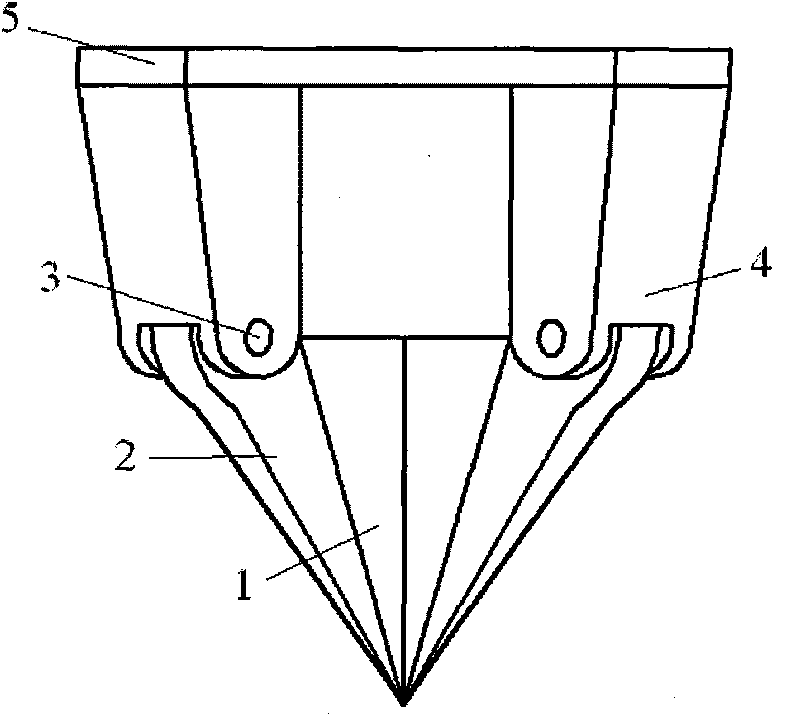

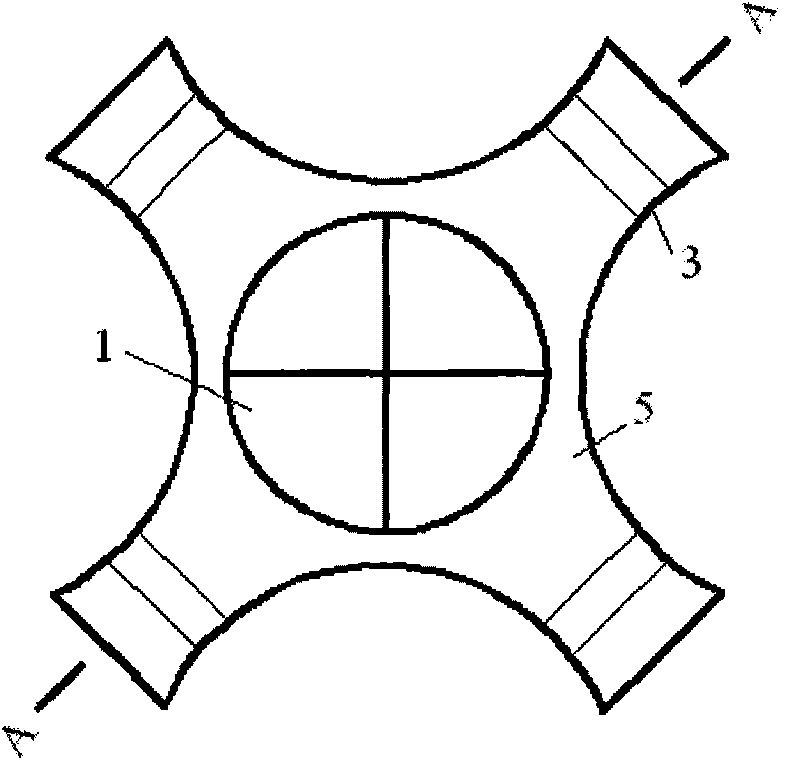

[0021] Such as figure 1 , 2 , 3, and 4 show:

[0022] The lower part of the X-shaped transition section 4 made of steel is hinged with the reinforcement 2 through the connecting hinge 3, and the valve 1 is composed of four curved triangular steel sheets with a large upper part and a smaller lower part; In the middle position of the valve 1, the reinforcement 2 and the valve 1 are fixedly connected as a whole; the connecting hinge 3 flexibly connects the upper ends of each reinforcement 2; when the valve 1 is not closed (such as figure 1 As shown), the four curved triangular steel sheets are separately separated, when closed (such as figure 2 Shown) four curved triangular steel sheets are rotated in the connecting hinge 3 by reinforcing the upper end of the valve 2, and the lower end of the valve 1 pile tip is gathered in the middle, and the whole is shaped like an inverted cone, so that the four curved triangular steel sheets of the valve 1 The lower ends of the pieces wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com