Process for removal of dissolved hydrogen sulfide and reduction of sewage BOD in sewer or other waste systems

a technology of dissolved hydrogen sulfide and sewage bod, which is applied in the direction of biological water/sewage treatment, sustainable biological treatment, multi-stage water/sewage treatment, etc., can solve the problem of instantaneous removal of hydrogen sulfide, and achieve the elimination or substantial reduction of hydrogen sulfide and other minor odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

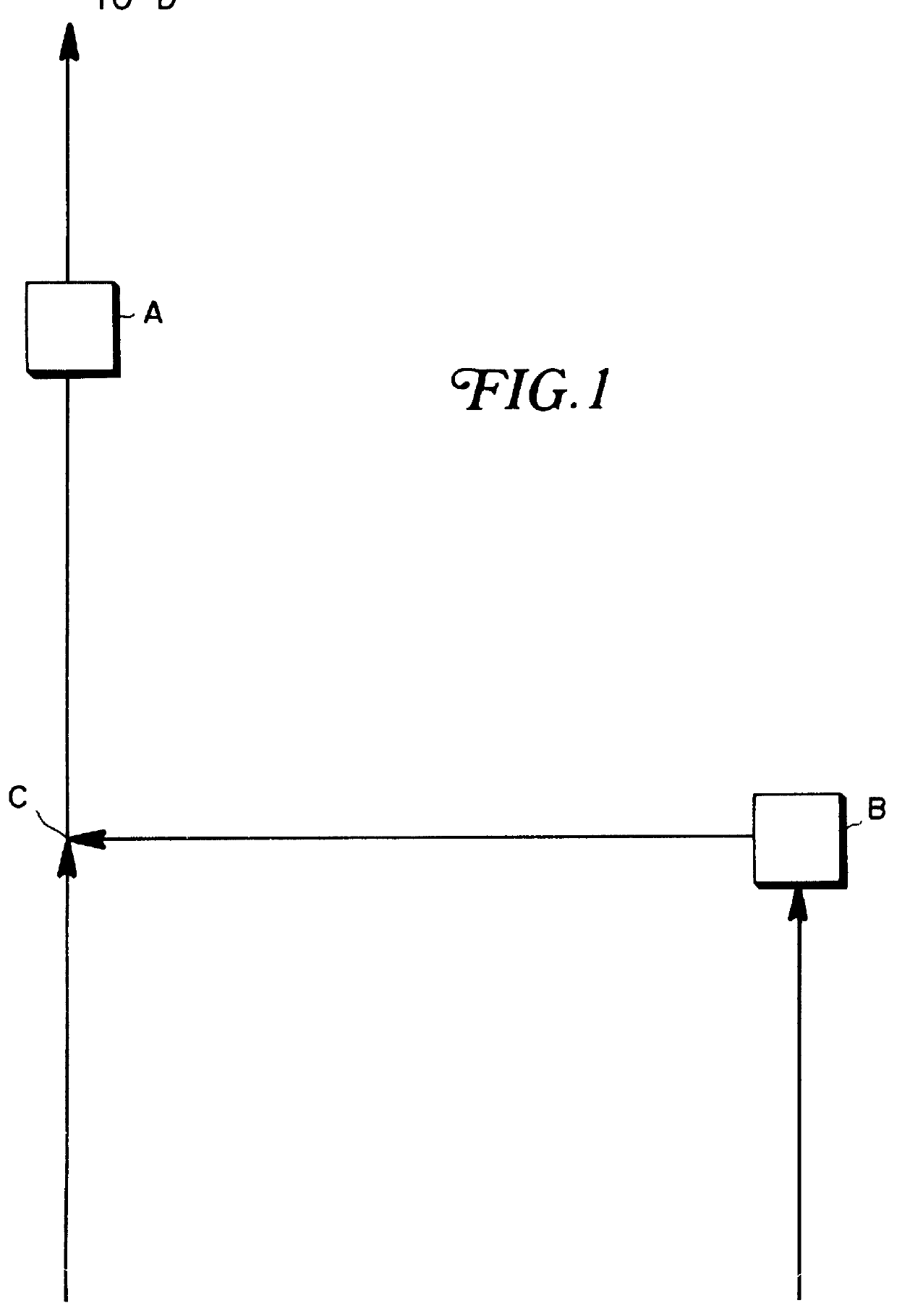

With reference to the FIGURE, sodium nitrate was added to a sewer system in Jacksonville, Florida at a master pump station, or feed point B, upstream of a second master pump station comprising a monitoring point A. The feed point B was at a point removed from an intersection C of the feed line and main sewage line, as indicated in the FIGURE.

The treated sewage continued to a downstream waste water treatment plant in Jacksonville, indicated as point D.

Average detention times (based on average daily flows, line sizes and lengths are as follows:

B.fwdarw.C 7 hours

C.fwdarw.A 3.3 hours

B.fwdarw.A 10.3 hours

In terms of the description provided above, the B.fwdarw.C distance and retention time of 7 hours constitutes the incubation period, coupled with the distance C.fwdarw.A and associated retention time of 3.3 hours comprises a total of 10.3 hours from addition of the nitrate station at point B to the monitoring at point A, thereby permitting sufficient time for the bacteria to culture.

The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com