Concentric co-extrusion die for extruding a multilayer thermoplastic film

a thermoplastic film and coextrusion die technology, applied in the field of concentration coextrusion die for extruding multi-layer thermoplastic film, can solve the problems of increased melt temperature and material degradation, complex internal construction of dies, and the size of dies that cannot reduce the thickness of specific layers, so as to improve the thickness tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

IN ACCORDANCE WITH THE INVENTION

[0054]In the examples described below, the mandrel exit diameter is shown to be 1800 mm. However co-extrusion dies according to the present invention can have any desired exit diameter, but are especially suitable for diameters in the range of 1300 to 2500 mm. The detailed design of all parts depends on the final application as well as required residence time, pressure and other rheological parameters.

[0055]In the detailed description that follows, all the data of the dies mentioned (dimensions, number of extruders, total number of layers, number of layers which are side fed with multiple inlets, number of inlets per layer, number of bifurcations, number of spirals overlaps, number of spirals, number of radial ports, inclination of ports, inclination of side feed inlets etc) are indicative and only for the purpose of the examples.

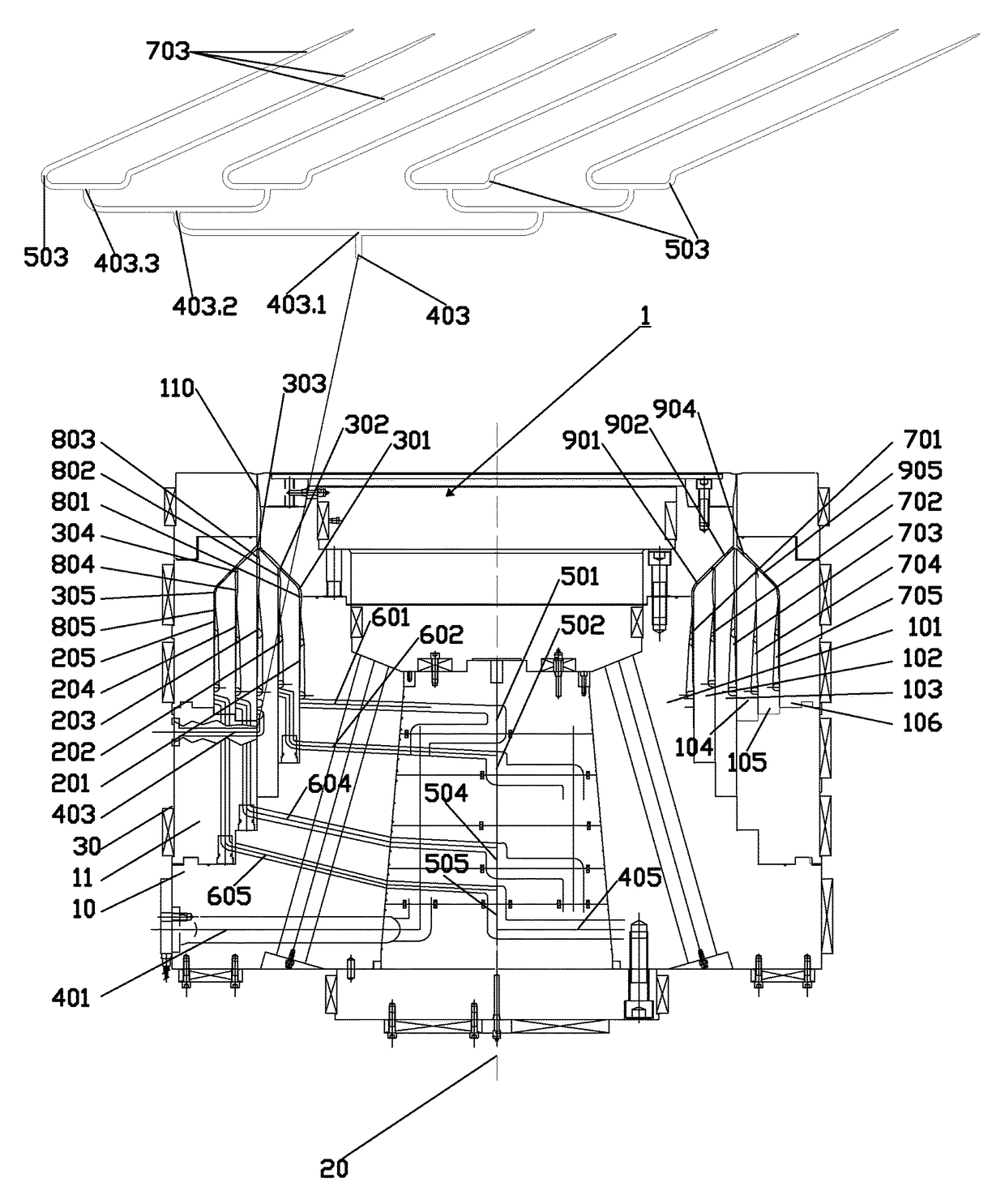

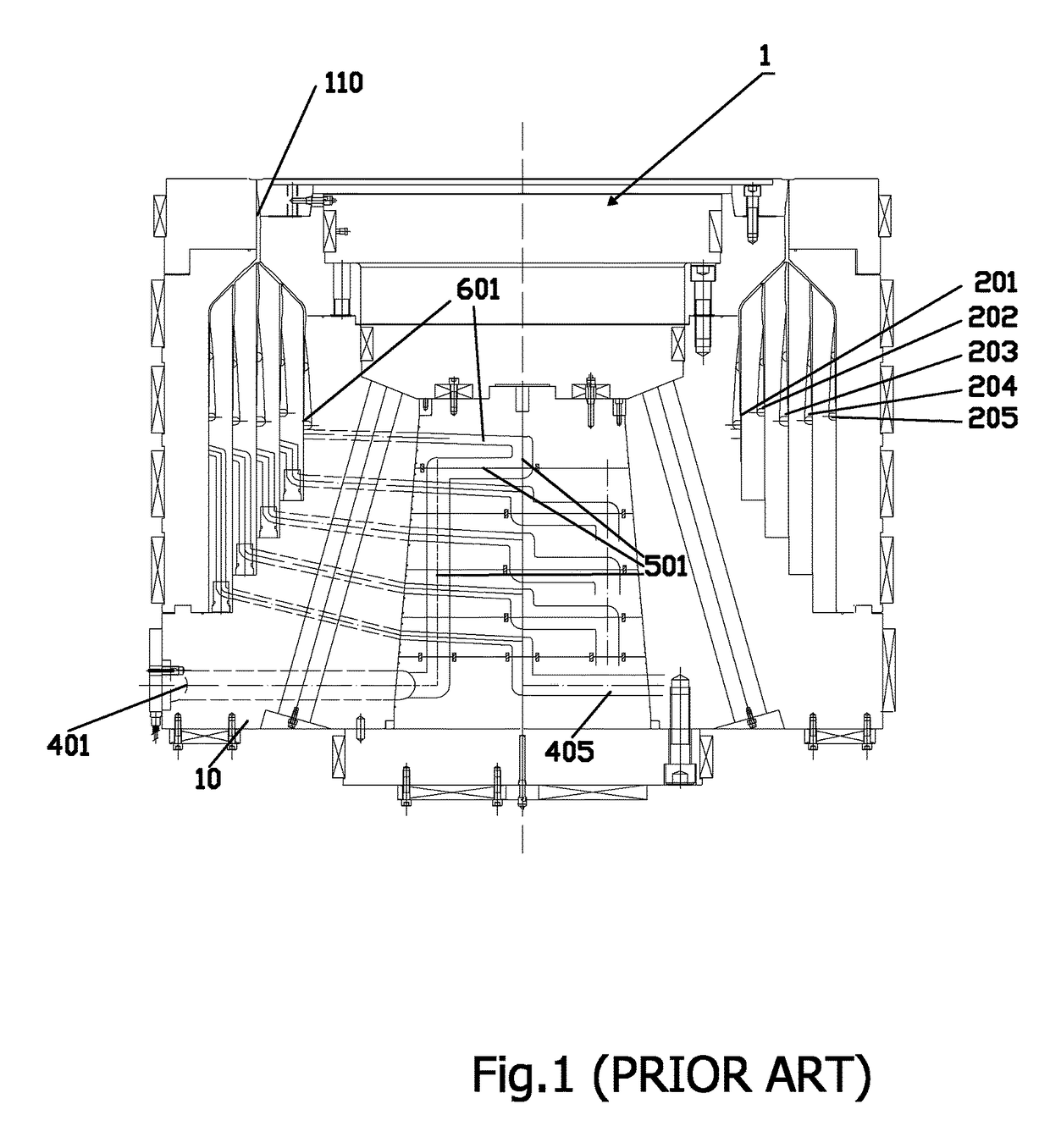

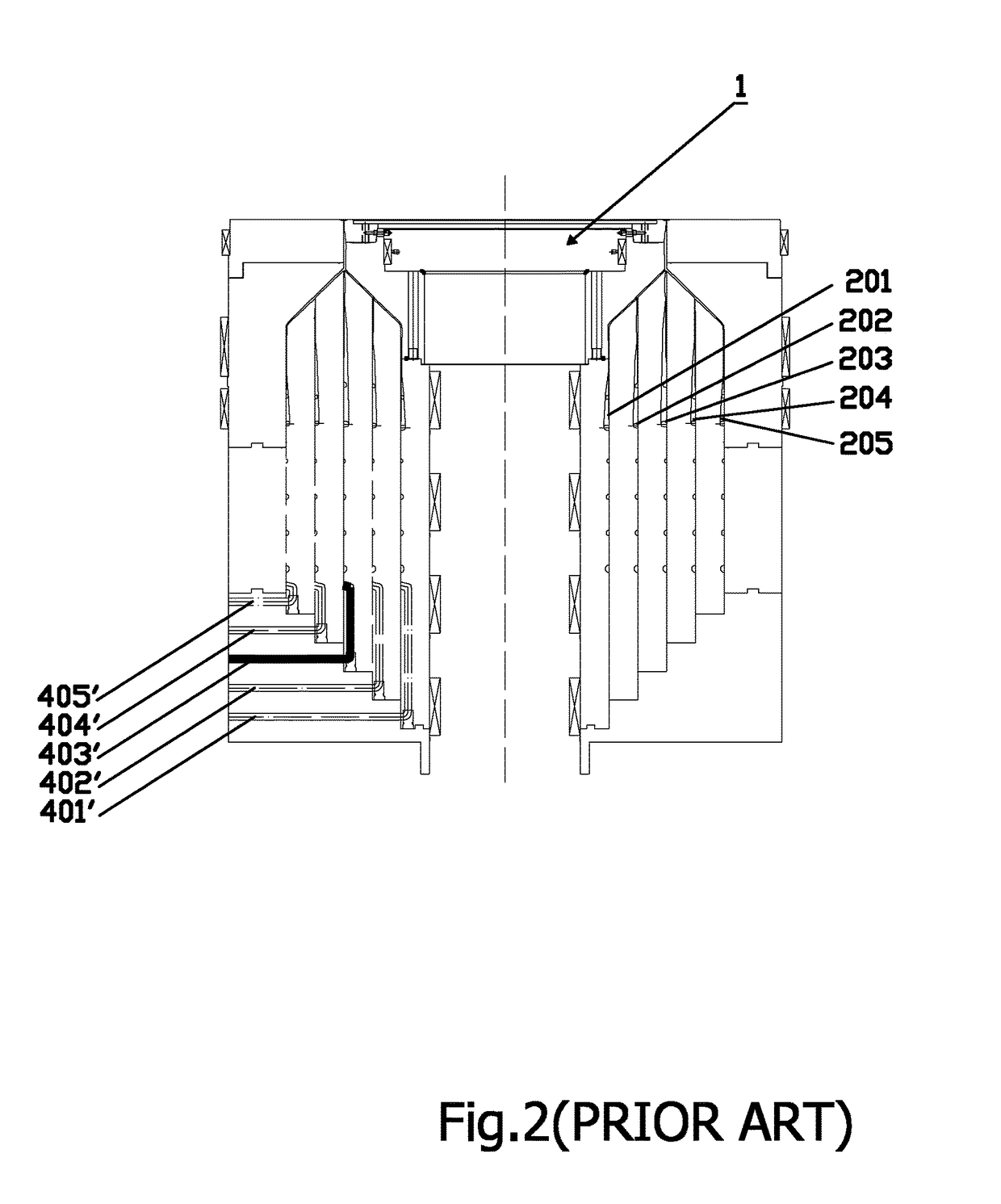

[0056]In FIG. 4, a longitudinal section of a first concentric co-extrusion die is shown as well as a developed partial annu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com