Terminal fitting and method of producing it

a technology of terminal fittings and fittings, applied in the direction of coupling contact members, coupling device connections, electrical devices, etc., can solve the problems of limited number of terminal fittings, and affecting the operation of the terminal fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

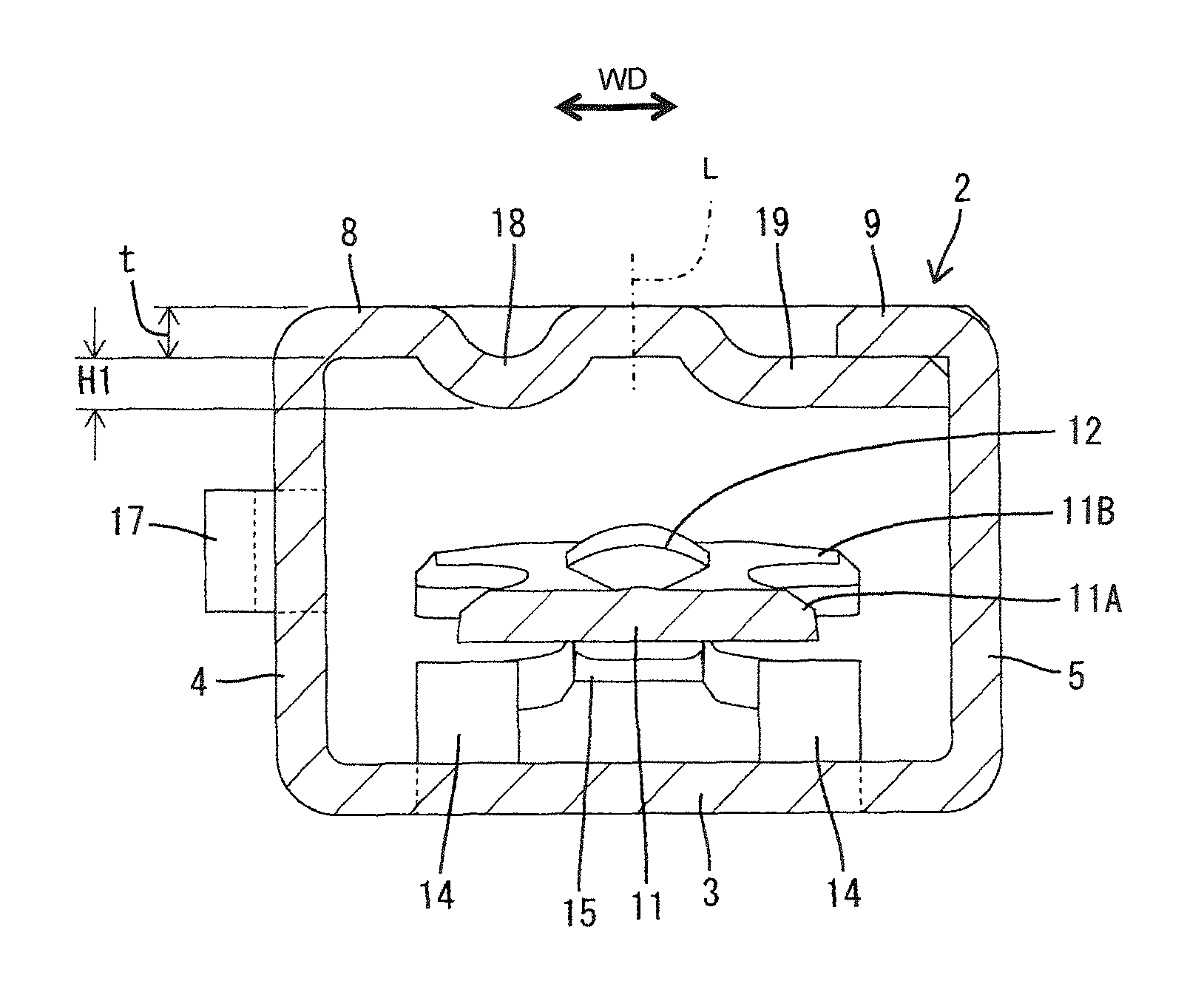

[0030]FIGS. 1 to 6 show a first particular embodiment of the present invention. As shown in FIG. 5, a terminal fitting T1 is in a developed state after a conductive plate material is punched or cut out into a specified shape. A multitude of terminal fittings T1 in the developed state are coupled to a carrier 1 in a chain-like manner in a longitudinal direction of the carrier 1. The terminal fittings T1 in the developed state are cut off from the carrier 1 in a later step and assembled as the terminal fittings T1 having a desired shape after respective bending, folding, embossing, punching, stamping and / or striking steps.

[0031]A hollow (in forward and backward directions) rectangular or polygonal tube 2 is formed on or near the front of each terminal fitting T1 and a wire connection portion comprising at least one wire barrel 6 to be crimped and connected to a wire core and at least one insulation barrel 7 to be crimped and connected to a wire coating to be connected to a wire is fo...

fourth embodiment

[0052]However, in the fourth embodiment, a ceiling plate 8 is deformed (e.g. struck or embossed or bent) such that a ceiling plate side contact portion 18 and a struck or bent portion 19 are continuous without forming any boundary. Specifically, the ceiling plate 8 is struck to have a substantially uniform depth over a width range extending from a position near a first side plate 4 to the extending end edge thereof, and the inner surface of this struck or bent part can be held in surface contact with a mating terminal M over a specified width range. The depth of this struck or bent part corresponds to a plate thickness as in the other embodiments.

[0053]Other configurations are similar or same as in the other embodiments and, hence, similar functions and effects can be achieved.

[0054]The invention is not limited to the above described and illustrated embodiments. For example, the following embodiments are also included in the technical scope of the present invention.

[0055]The height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com