Methods for producing linear alkylbenzenes, paraffins, and olefins from natural oils and kerosene

a technology of natural oils and kerosene, which is applied in the direction of organic chemistry, chemical apparatus and processes, hydrocarbon oil treatment products, etc., can solve the problems of linear alkylbenzenes, paraffins, and olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]The following detailed description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding background or the following detailed description.

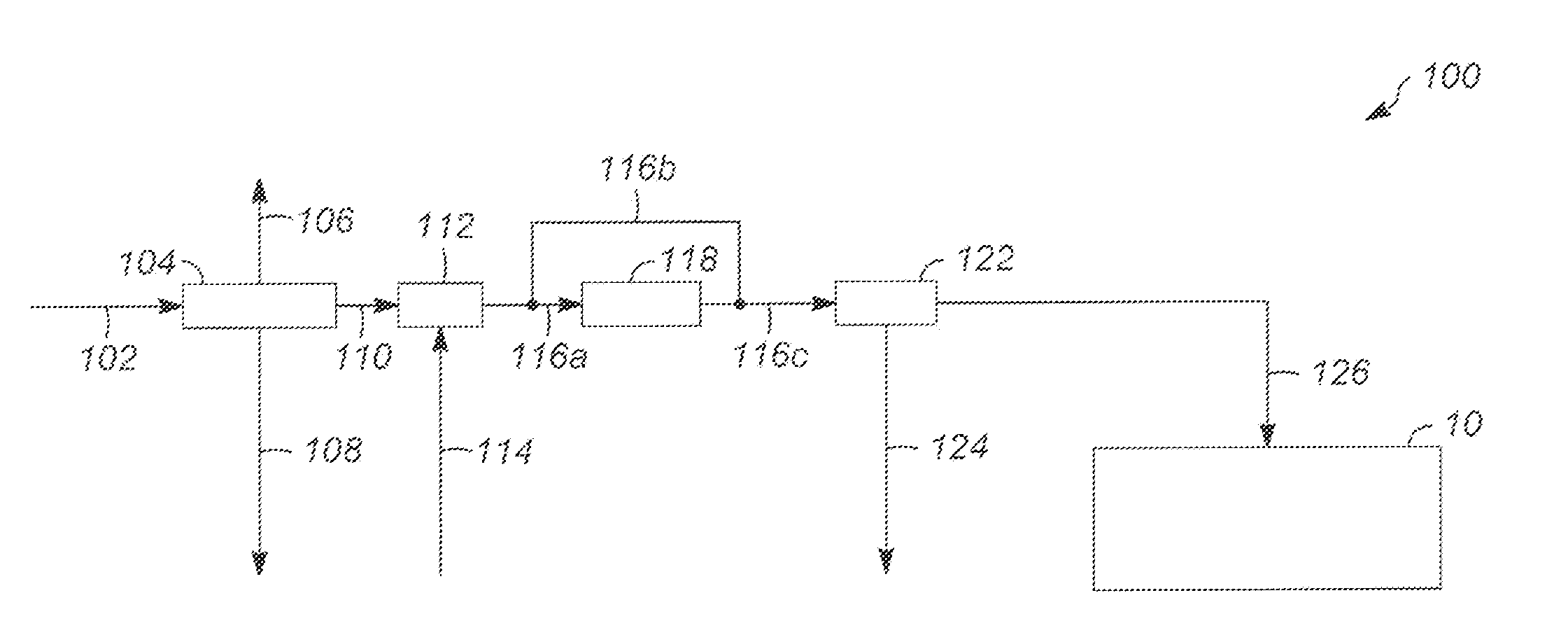

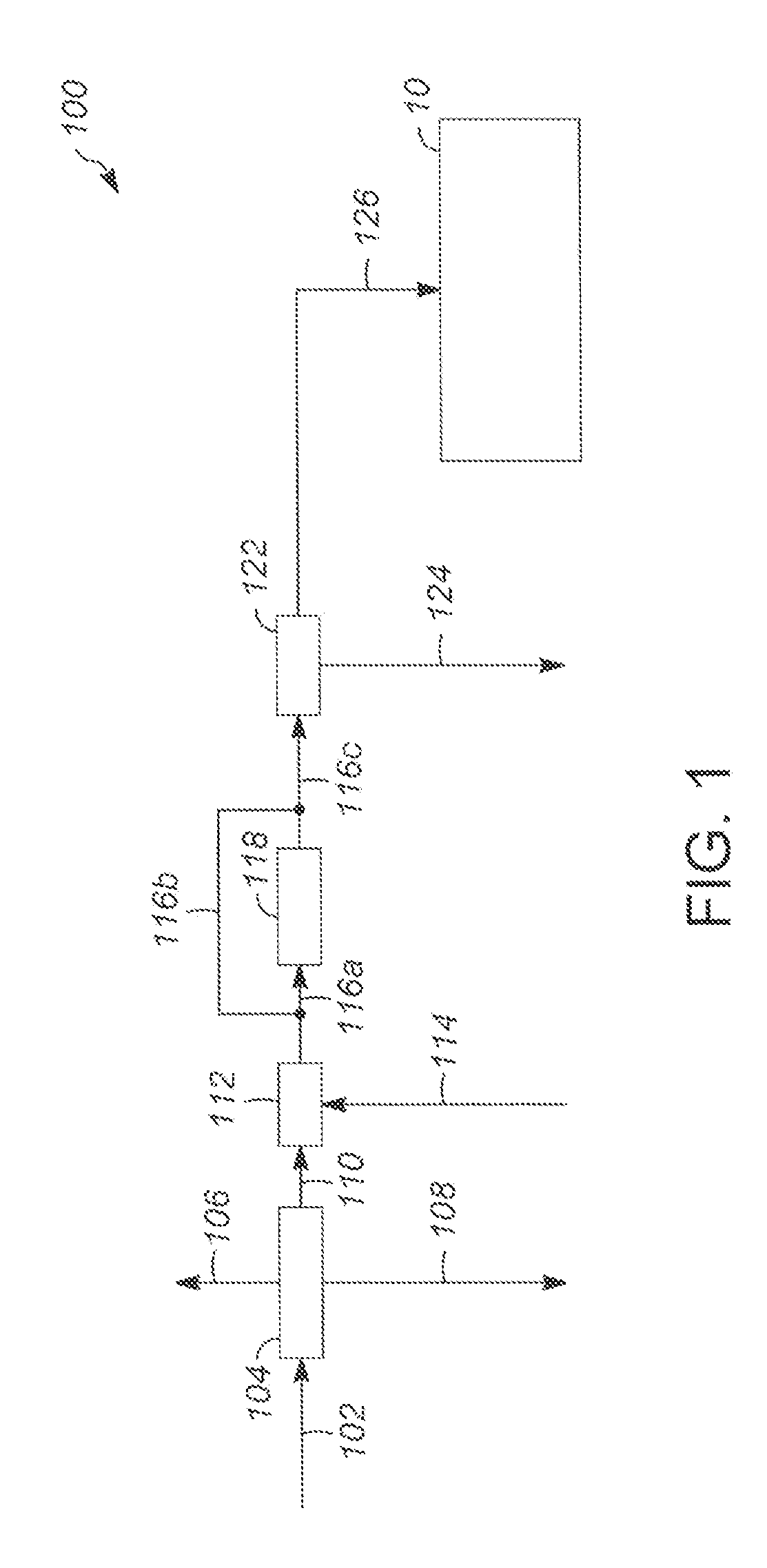

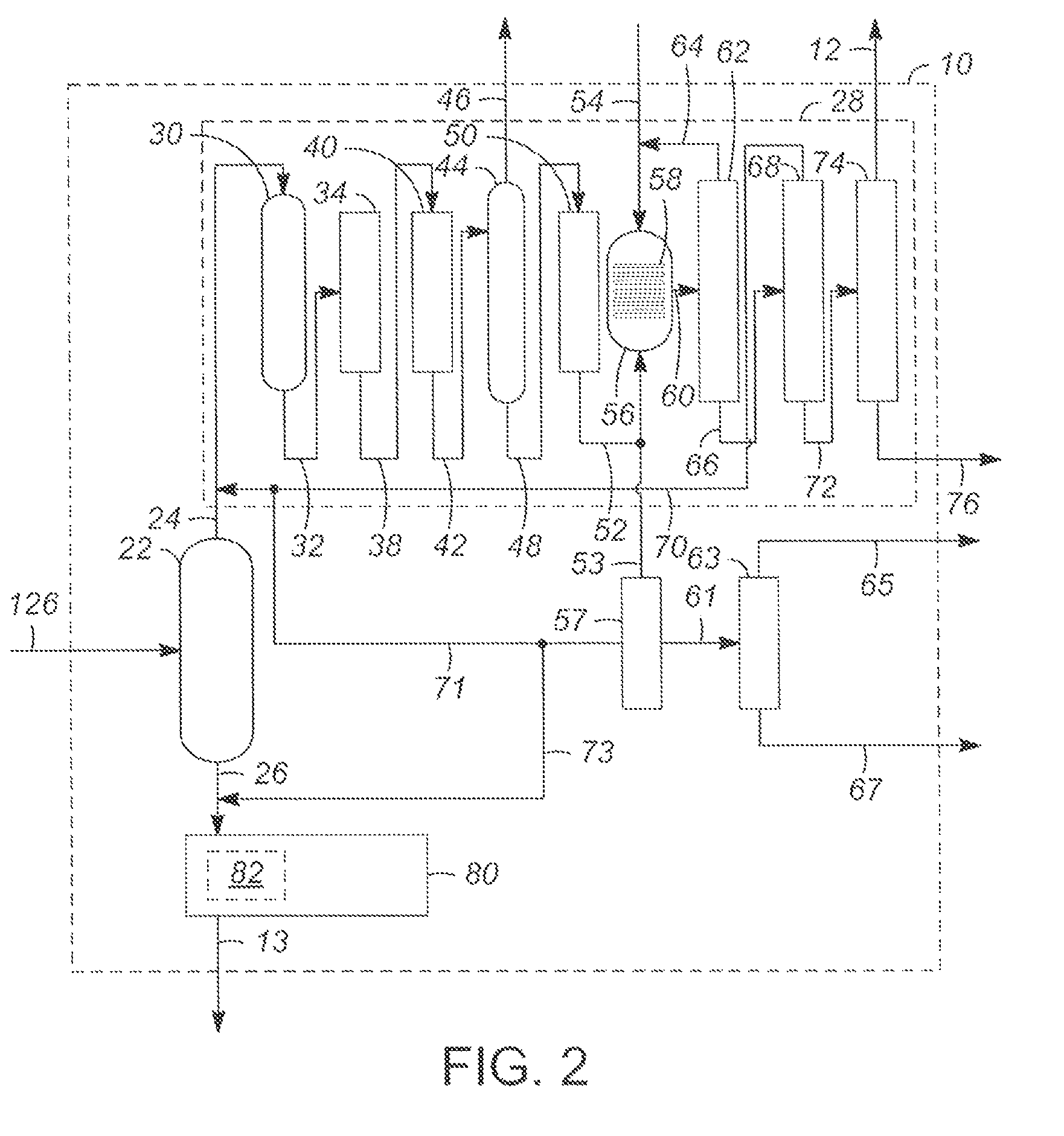

[0014]Various embodiments contemplated herein relate to methods for producing a linear alkylbenzene, paraffin, or olefin product from natural oils and kerosene. It will be appreciated that embodiments of the present disclosure allow for increased use of the C10 content in the kerosene feed. As will be appreciated by those having ordinary skill in the art, only a certain percentage of C10 (generally about 10% to about 15%) is allowed to be included in a linear alkylbenzene product for use in detergents. Traditionally, where only kerosene was used as a feedstock, any C10 present in an amount beyond this maximum needed to be removed from the system and discarded or put to use for the production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| reaction kinetics | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com