Plastic fuel tank

a fuel tank and plastic technology, applied in the field of plastic or resinous fuel tanks, can solve the problems of degradation of ethylene/vinyl alcohol copolymer, and achieve the effects of reducing the cost of plastic fuel tanks, reducing the cost of recycled polyethylene materials, and eliminating concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

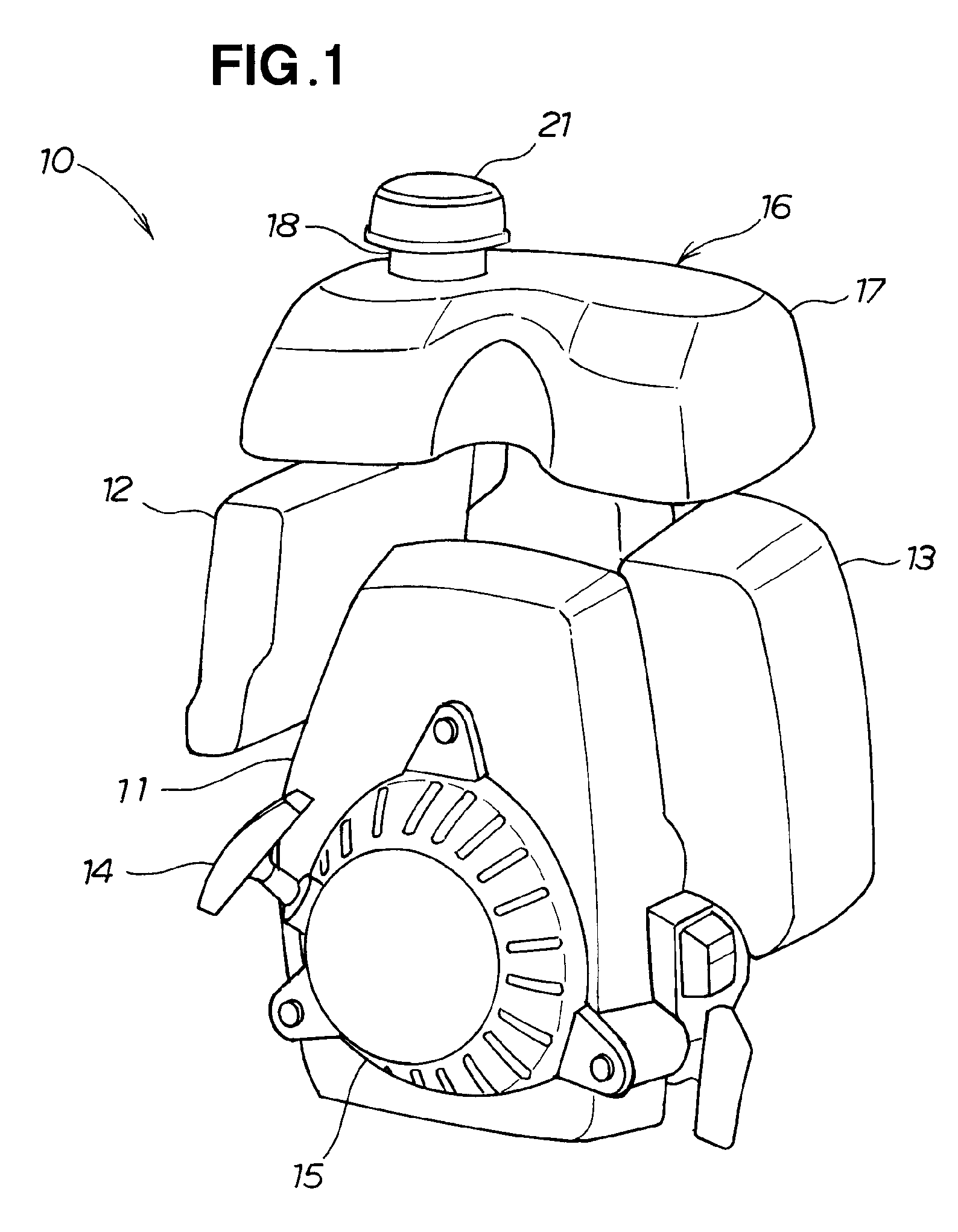

[0022]As shown in FIG. 1, a general-purpose engine 10 includes an engine assembly 11, a suction part 12 provided to a side part of the engine assembly 11 and used to draw outside air into the engine assembly 11, an exhaust part 13 provided to a side part of the engine assembly 11 and used to discharge exhaust from the engine assembly 11 to the exterior, a recoil starter 14 provided to a lower part of the engine assembly 11 and used to start up the engine assembly 11, and a recoil starter cover 15 for covering the recoil starter 14.

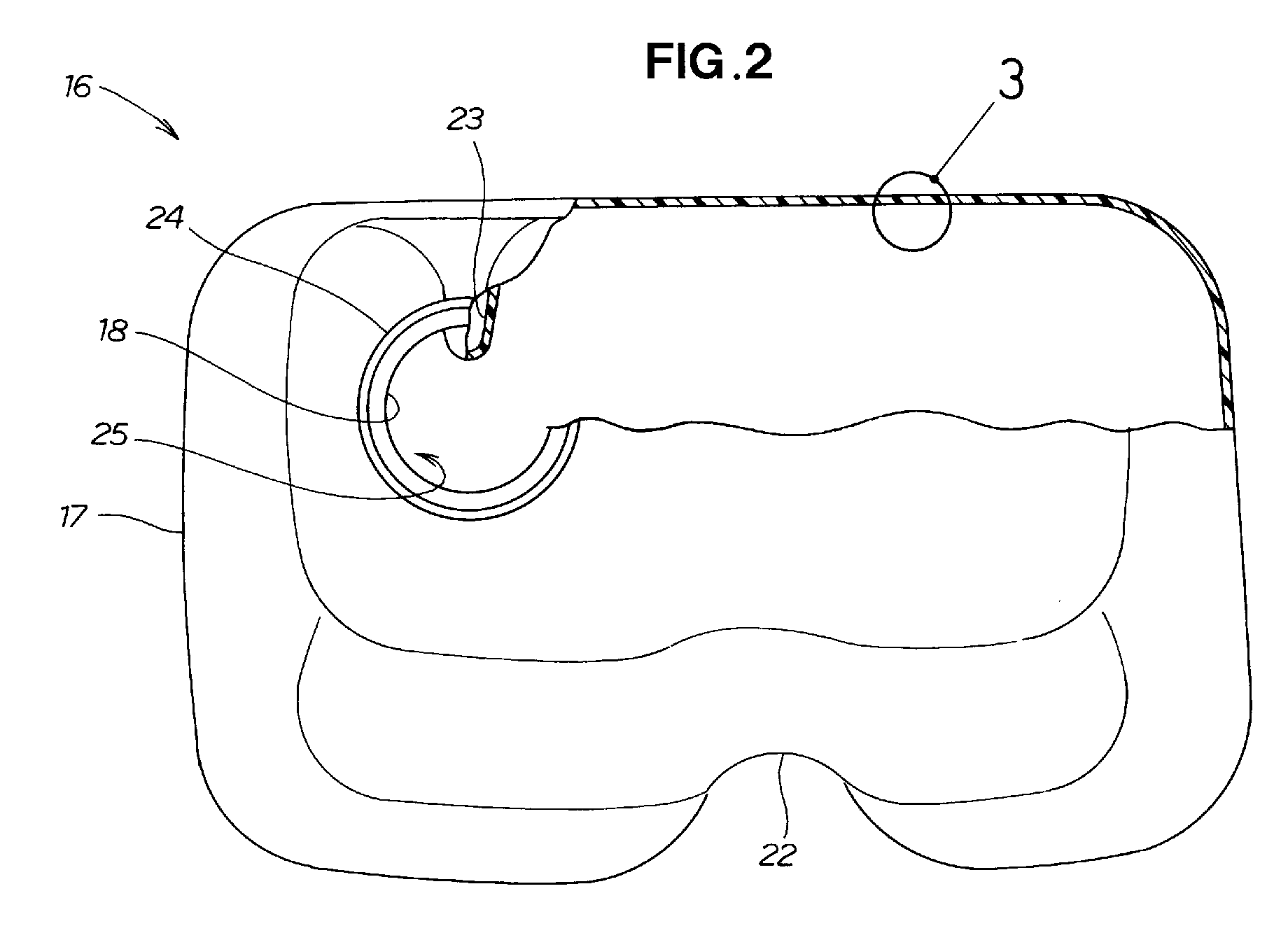

[0023]The general-purpose engine 10 is also provided with a plastic fuel tank 16 for storing fuel in the upper part of the engine assembly 11. The plastic fuel tank 16 includes a tank assembly 17 for storing fuel, a filler neck 18 molded integrally with the tank assembly 17 and used to introduce fuel, and a filler cap 21 mounted on the filler neck 18 and used to block the filler neck 18.

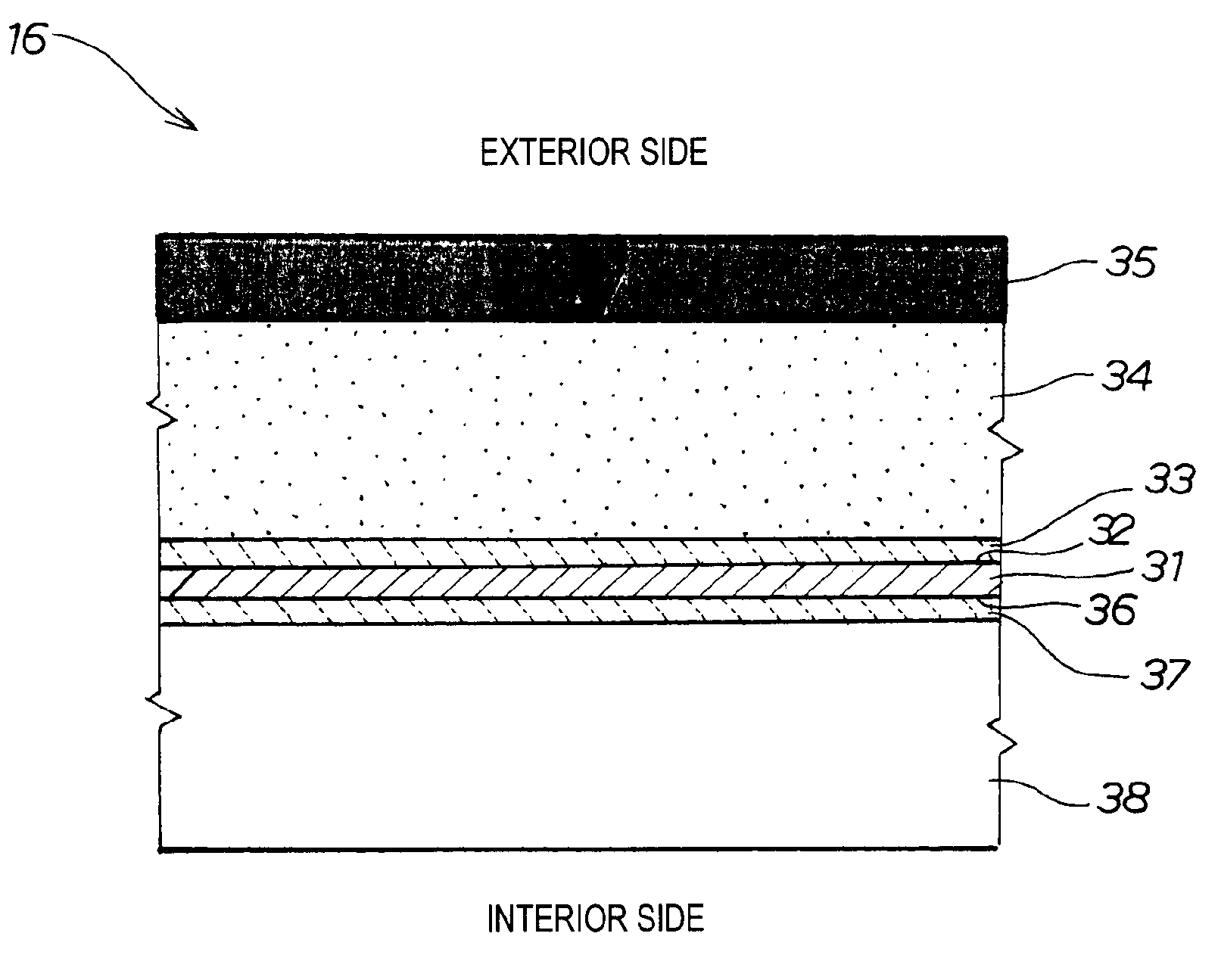

[0024]As shown in FIG. 2, the tank assembly 17 of the plastic fuel tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| weather resistance | aaaaa | aaaaa |

| transmission | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com