Arrangement, device and method at a disturbance-eliminating valve for damper

a technology of disturbance-eliminating valves and dampers, applied in the field of damper arrangements, can solve the problems of not solving the problem in a correct way, the damage relating to the function of the valve on the low pressure side can be lost, and the sound is particularly irritating to the human ear, so as to achieve the effect of avoiding damage and avoiding damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

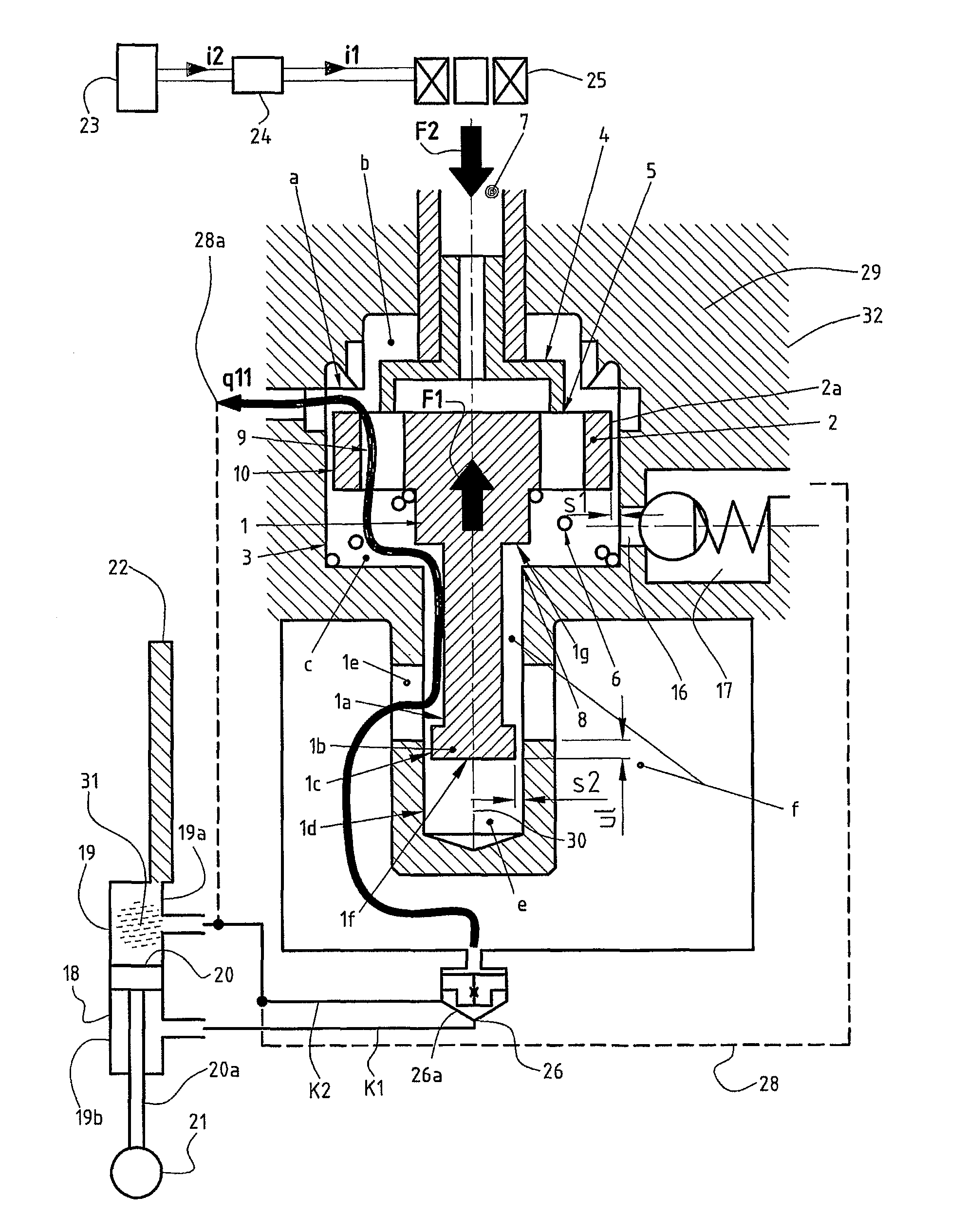

[0039]FIG. 1 shows the arrangement / valve with an activated valve actuator and FIG. 2 shows the arrangement / faces towards the actuator provided with a disk-shaped first piston 2, which is guided against valve in deactivated state. A valve piston 1 is on a part that an inner wall 3 of the pilot housing and which makes contact in an axial direction with an actuator pin 4 in a plane 5 perpendicular to the direction of movement.

[0040]The valve piston 1 of the pilot valve is acted upon in one direction by a first force F1 from a spring 6 or a device exerting a biasing force and by forces that result from pressure exerted in the chambers e and f. The valve piston 1 also is acted upon in a second direction by a second force F2 from an actuator 7 in the activated state. The pilot cone is normally located several hundredths from a control edge 8.

[0041]In its extension, the valve piston 1 is provided with an extension part 1a and a second piston 1b. A guide face 10 of the second piston 1b pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com