Piping bag, blank for manufacturing a piping bag and method of manufacturing a piping bag

a manufacturing method and piping bag technology, applied in the field of piping bags, can solve the problems of difficult handling of piping bags during manufacturing and in connection with the dispensing operation, and achieve the effect of reducing or eliminating the problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

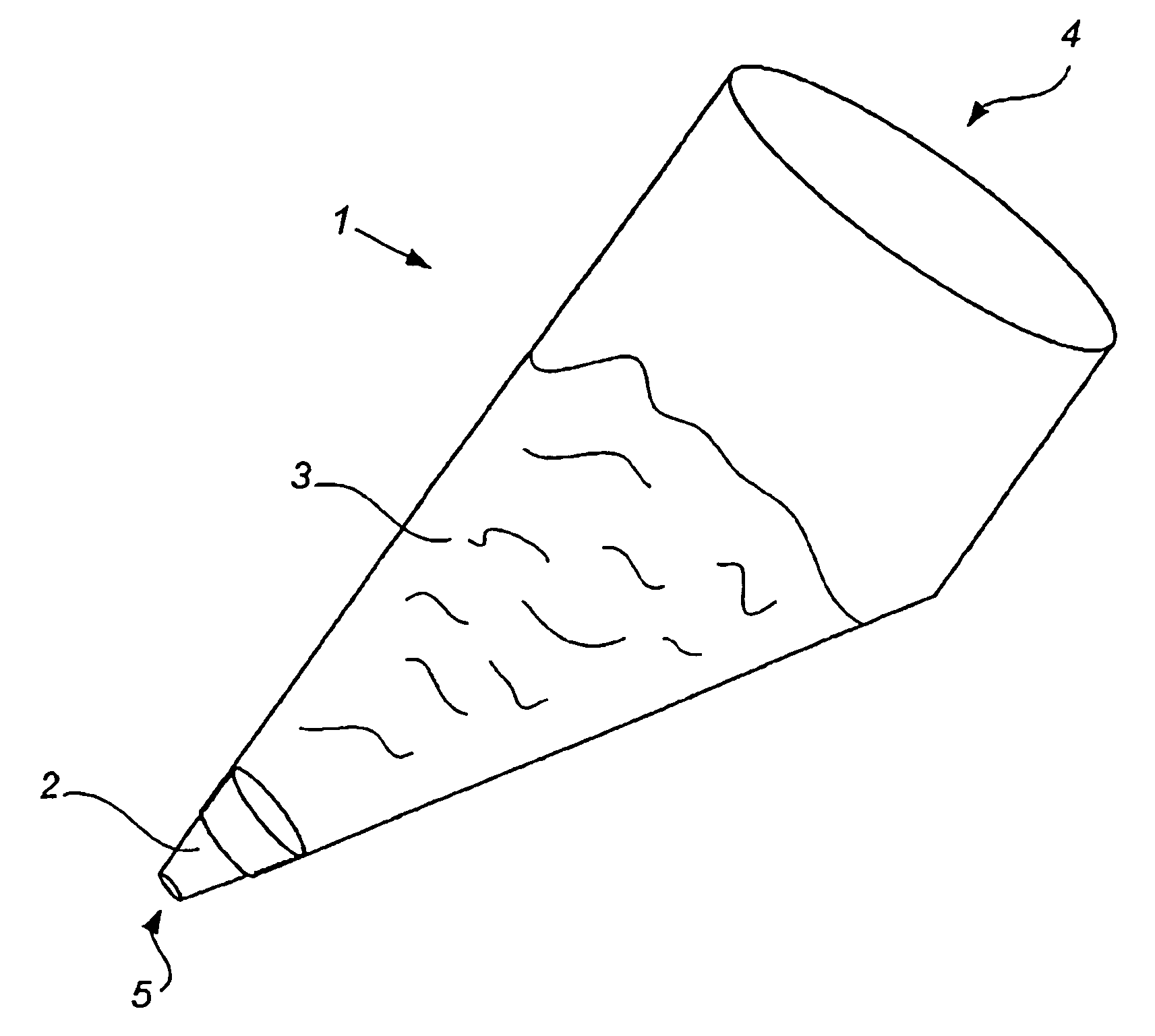

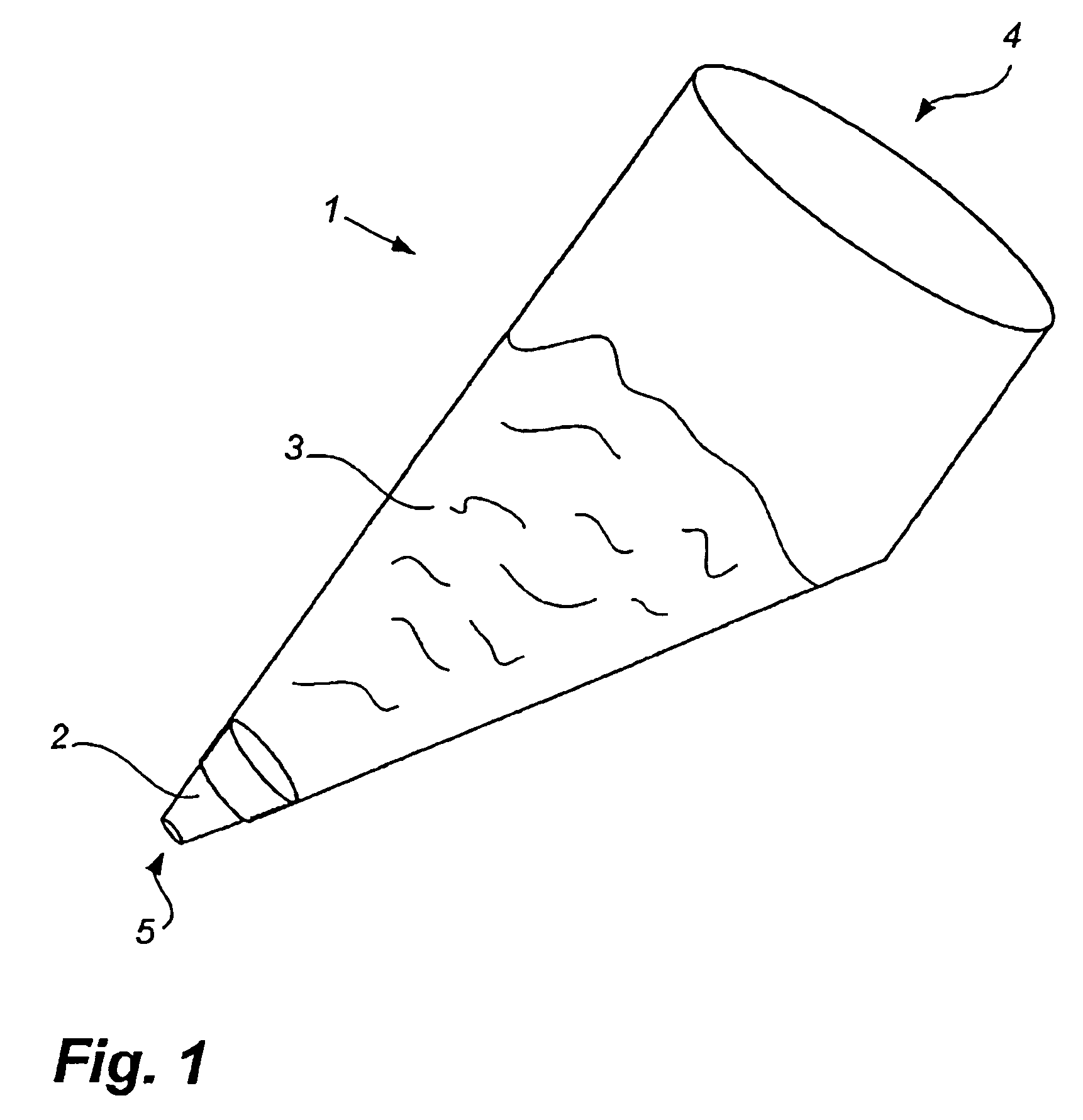

[0023]FIG. 1 shows a piping bag 1, which at a dispensing orifice 5 is provided with a nozzle 2 and which through an open end 4 has been filled with a flowable paste 3. The flowable paste 3 is dispensable through the nozzle 2 when the open end 4 of the piping bag 1 is closed, for example folded, and the piping bag 1 compressed.

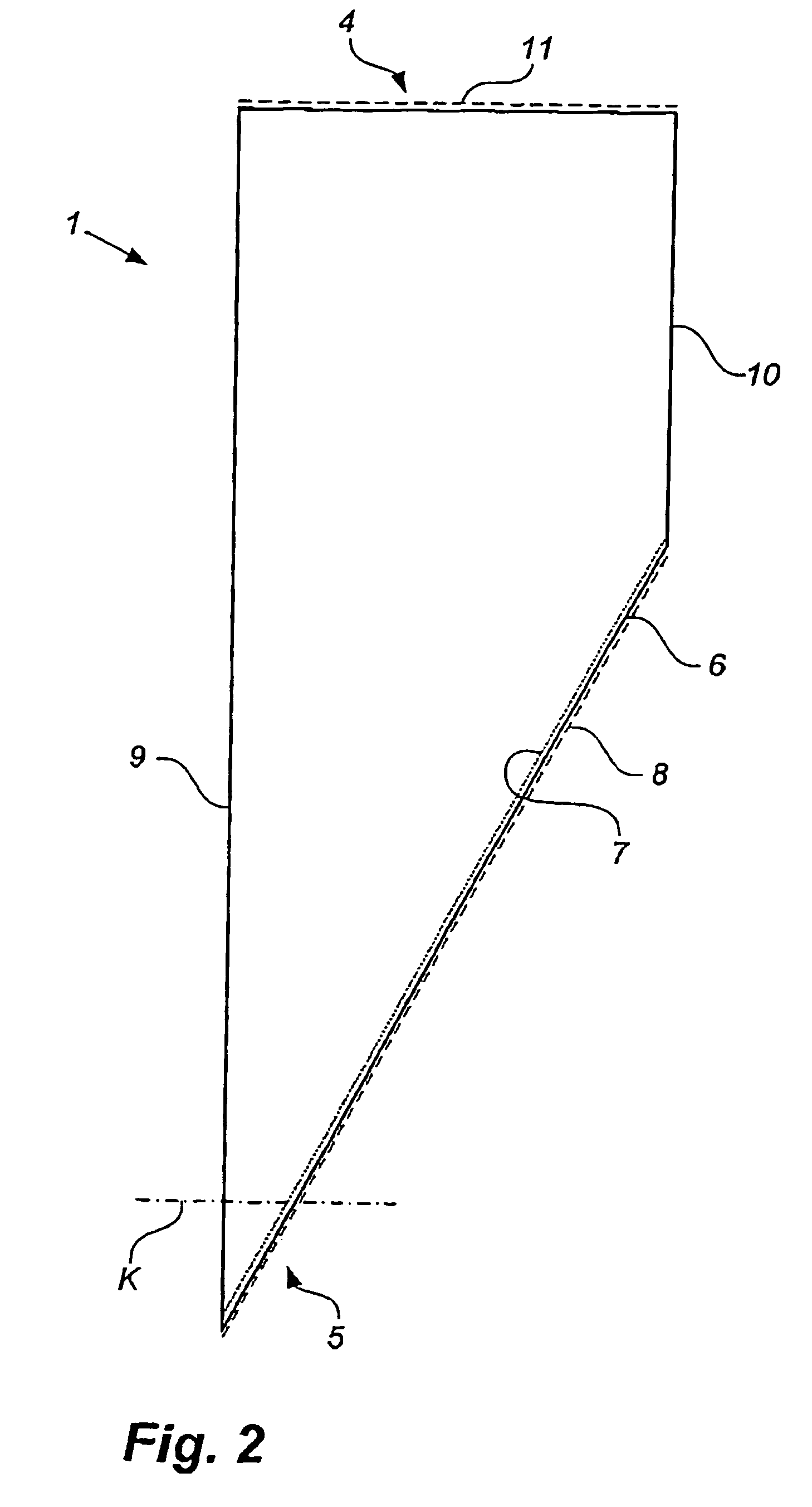

[0024]With reference to FIG. 2, the piping bag 1 is formed from a polymer tube segment, preferably of polyolefin plastic, such as polyethylene, polypropylene or the like. When unfilled, as shown in FIG. 2, the piping bag 1 has an essentially two-dimensional extension, its shape being defined by two parallel creases at the edges 9, 10, formed by the polymer tube being collapsed, and a joint 7 that is obliquely transversal to the edges 9, 10. A severance mark 8 runs parallel to the joint 7, which mark 8 is achieved in a manner obvious to a person skilled in the art, for example by means of perforation. At the open end 4 of the piping bag 1, a severance mark 11 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com