Subsurface imaged labels and tags using thermal transfer ribbon carrier as overlaminate and method of manufacture

a thermal transfer ribbon carrier and subsurface image technology, applied in the field of durable thermal transfer images, can solve the problems of adhesives and chemicals, and achieve the effect of easy removal of the liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

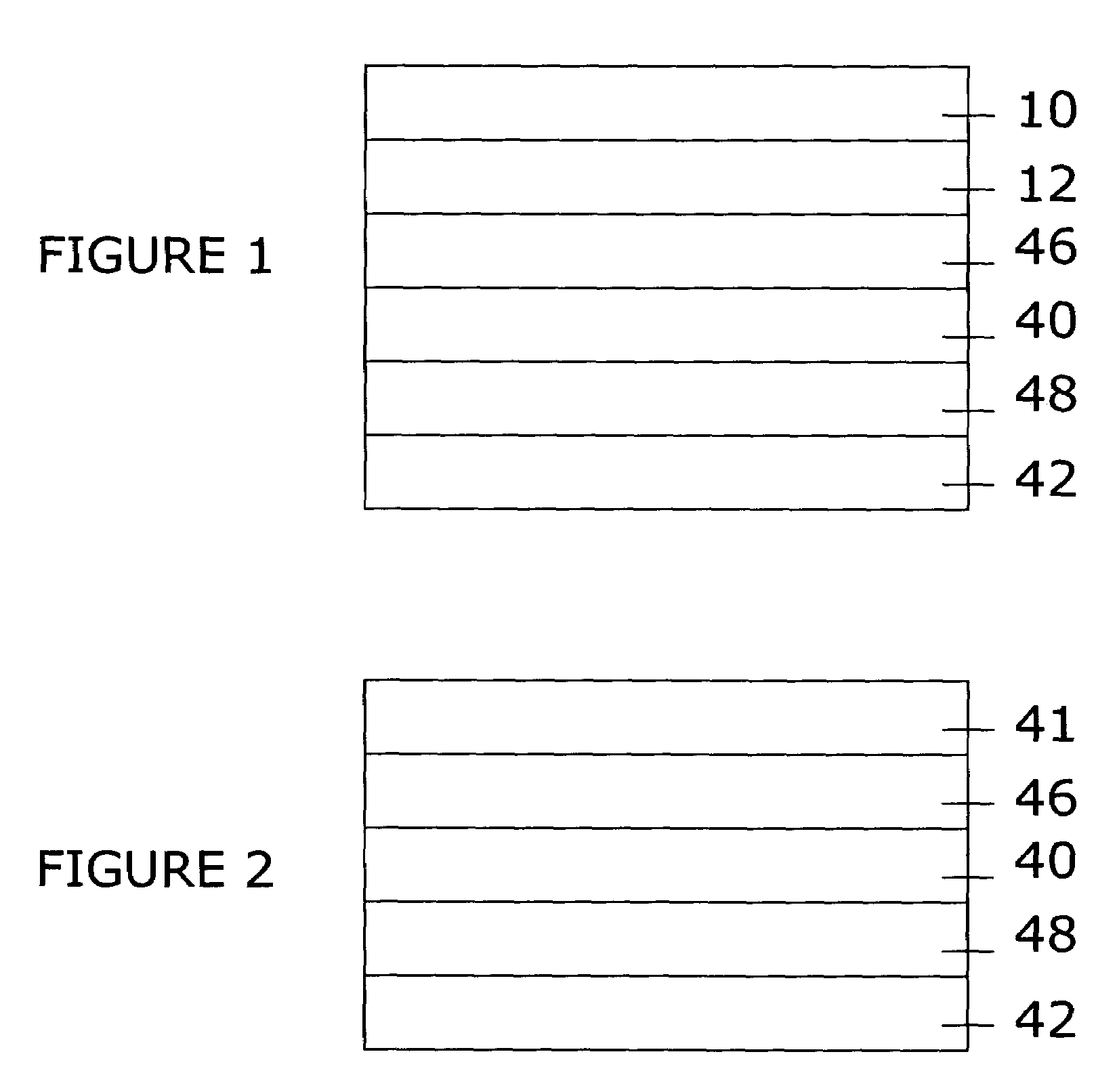

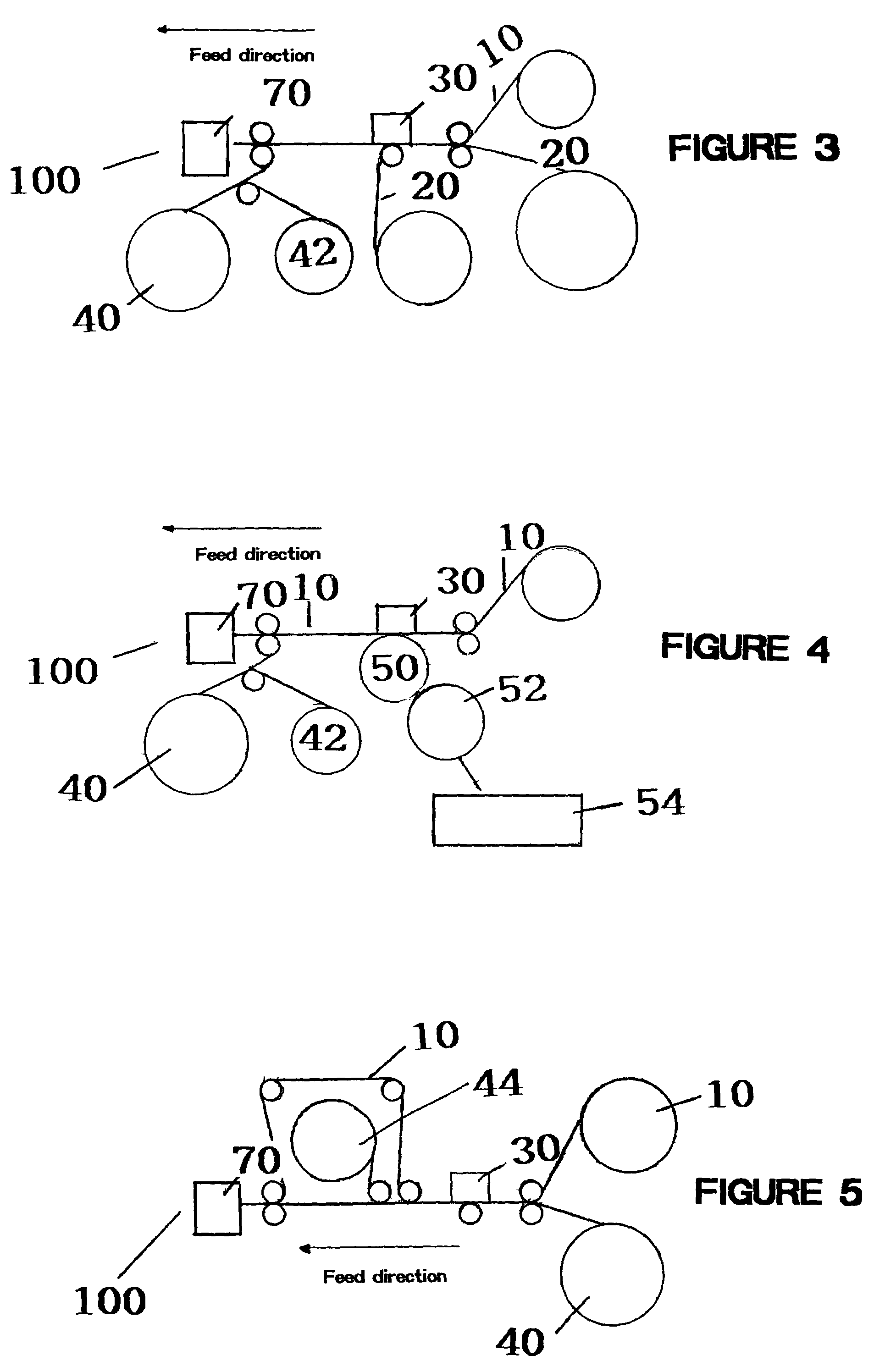

[0021]Thermal transfer printing traditionally involves variably boding ink from a thin PET carrier 10 (ink, carrier, and release coating comprising a ribbon) to a substrate. A positive image is printed on a substrate. The PET carrier 10 is then stripped away from the substrate, removing the ink from all areas that have not been bonded via heat and pressure. While the printed image is fairly durable, it is subject to attack from abrasion and chemicals, particularly solvents similar to the ones used to coat the ink on the PET carrier.

[0022]The inventive method is a new method of protecting printed images from challenging application conditions such as chemical exposure and abrasion and an inventive label construction.

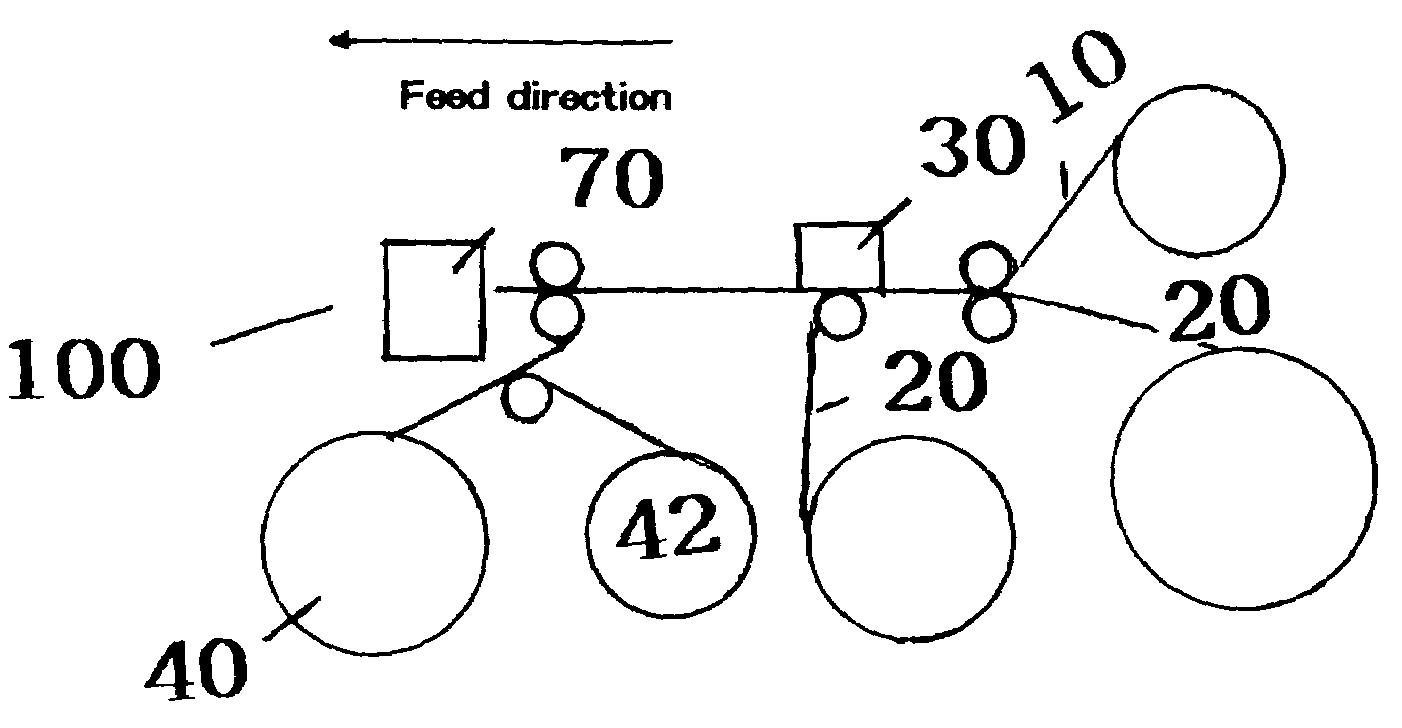

[0023]This invention changes the use of thermal transfer technology. The thermal transfer ribbon is imaged onto a waste medium 20 rather than onto the target substrate. The negative of the desired image on the waste medium is stripped away leaving the image on the PET car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal transfer | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

| pressure sensitive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com