Co-planarity examination method and optical module for electronic components

a technology of optical modules and electronic components, applied in the field of machine vision, can solve the problems of inability to get separated images of electronic parts, inability to measure or handle parts causing specular reflections, and current systems have problems, so as to achieve accurate measurement of selected parts of a device, ensure the accuracy of measurement made on the part, and reduce the effect of problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

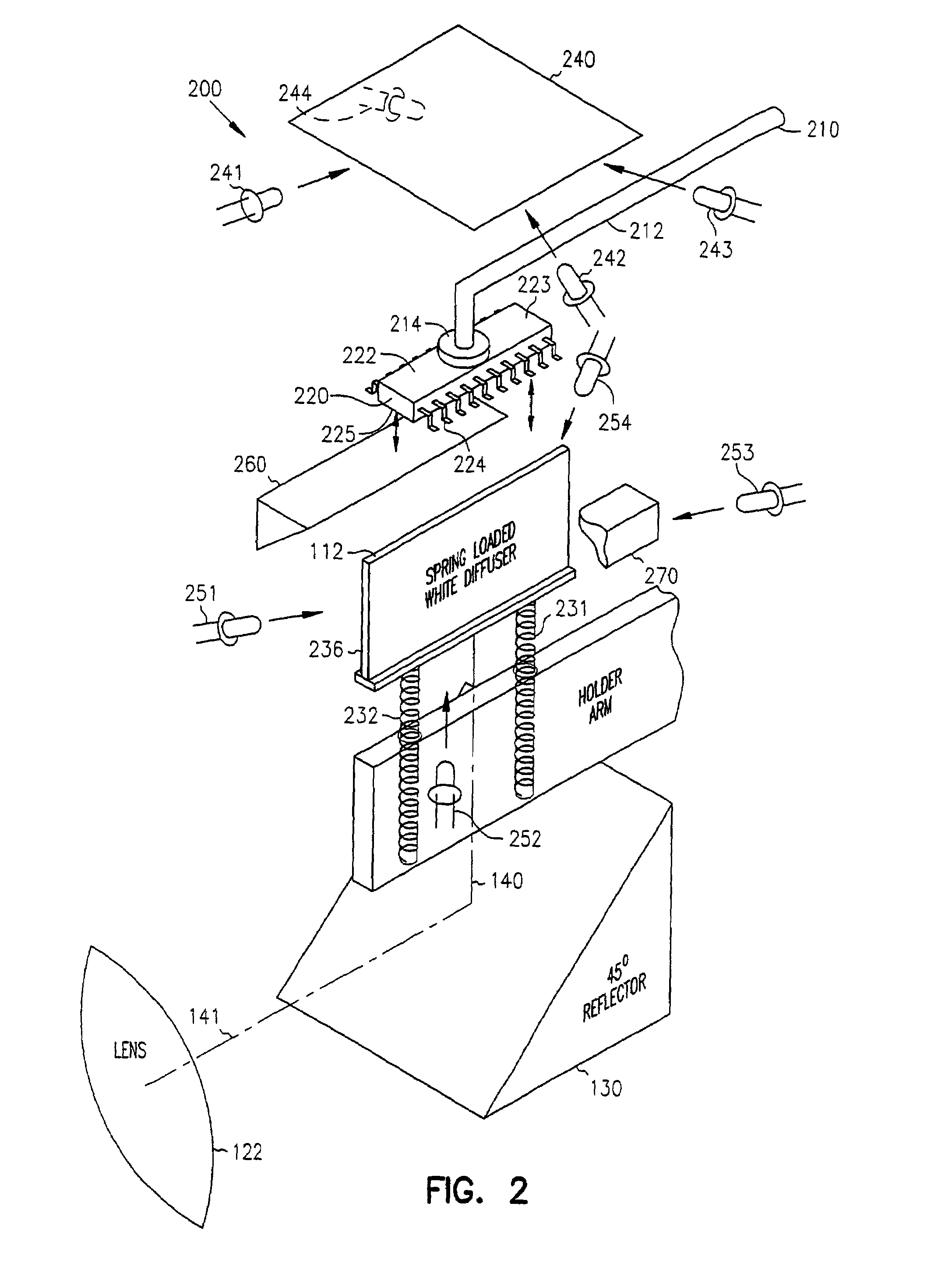

[0041]FIG. 2 is an exploded view of the present invention. FIG. 2 includes a lens 122 of the image device 120 as well as the 45° reflector or mirror 130 which converts a light path 140 from a substantially vertical orientation to a light path 141 having a substantially horizontal orientation and directed toward the lens 122 of the image device (shown in FIG. 1). The machine-vision system 200 shown in FIG. 2 includes a vacuum pick-and-place machine 210 which includes a vacuum line 212 and a vacuum pickup end 214. The vacuum pick-and-place apparatus 210 picks up objects 220 or devices under test 220 which are to be inspected. As shown in FIG. 2, the object 200 or device under test 220 is a surface-mount technology package having a substrate 222 and gull-wing type leads 224. The gull-wing shaped leads 224 are on a first side or edge and a second side or edge of the substrate 222. In other embodiments, the device under test includes solder balls affixed to the bottom surface, some of wh...

embodiment 600

[0051]FIG. 6A is a schematic view of another embodiment of the present invention 600 in which one diffuser 240 is positioned above the device under test 220. A pick-and-place assembly 210 places a part under test or device under test 220 onto a base 610. The base includes a diffuser 630 attached a portion of the base 610 which is closest to the second major surface 225 of the device under test 220. The base 610 also includes a first 45° mirrored or reflective surface 614 and a second mirrored or reflective surface 616 which is also at 45°. Light is directed at the top-down view diffuser 240 as well as at the diffuser 630. In one embodiment, the LEDs are used as light sources to back light the diffuser 630 in the top-down view diffuser 240. Also included in the machine-vision system 600 is a left-side mirror 260 and a right-side mirror 270. In addition to the left-side mirror 260, there is a first lower side mirror 660 and a second lower side mirror 662. Both of these mirrors 660, 66...

embodiment 700

[0055]In some embodiments, the L-shaped diffuser 732, 731 is backlit and can be used for both the top-down views 780, 782 and the side views 790, 792. The embodiment 700, shown in FIG. 7A, includes a base 750. The base 750 includes mirrored surfaces 614 and 616. The device under test 220 does not have to contact a portion of the base and, therefore, the base 750 does not have to be spring loaded. In some embodiments, the base may be extended to include the mirrors 662 and 672. With respect to the light paths needed to obtain all four of the images 780, 782, 790, 792, the light paths are essentially the same as those shown and described in FIG. 6A with the exception that the gull-wing leads shown are on a part that is in the dead-bug position. Each of the paths A1, A2, B1, B2 are equal in length so that the lens 122 need not accommodate different focal lengths. The light path A1 is essentially the same in FIG. 7A as in FIG. 7B and the light path B1 is essentially the same in FIG. 7A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| elastomeric | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com