Device and method for cleaning a surface of a rotating cylinder, such as a plate cylinder of a printing press or other

a technology of rotating cylinders and cleaning methods, which is applied in the field of cleaning devices, can solve the problems of deterioration in quality, weakened to the point of breaking, and printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

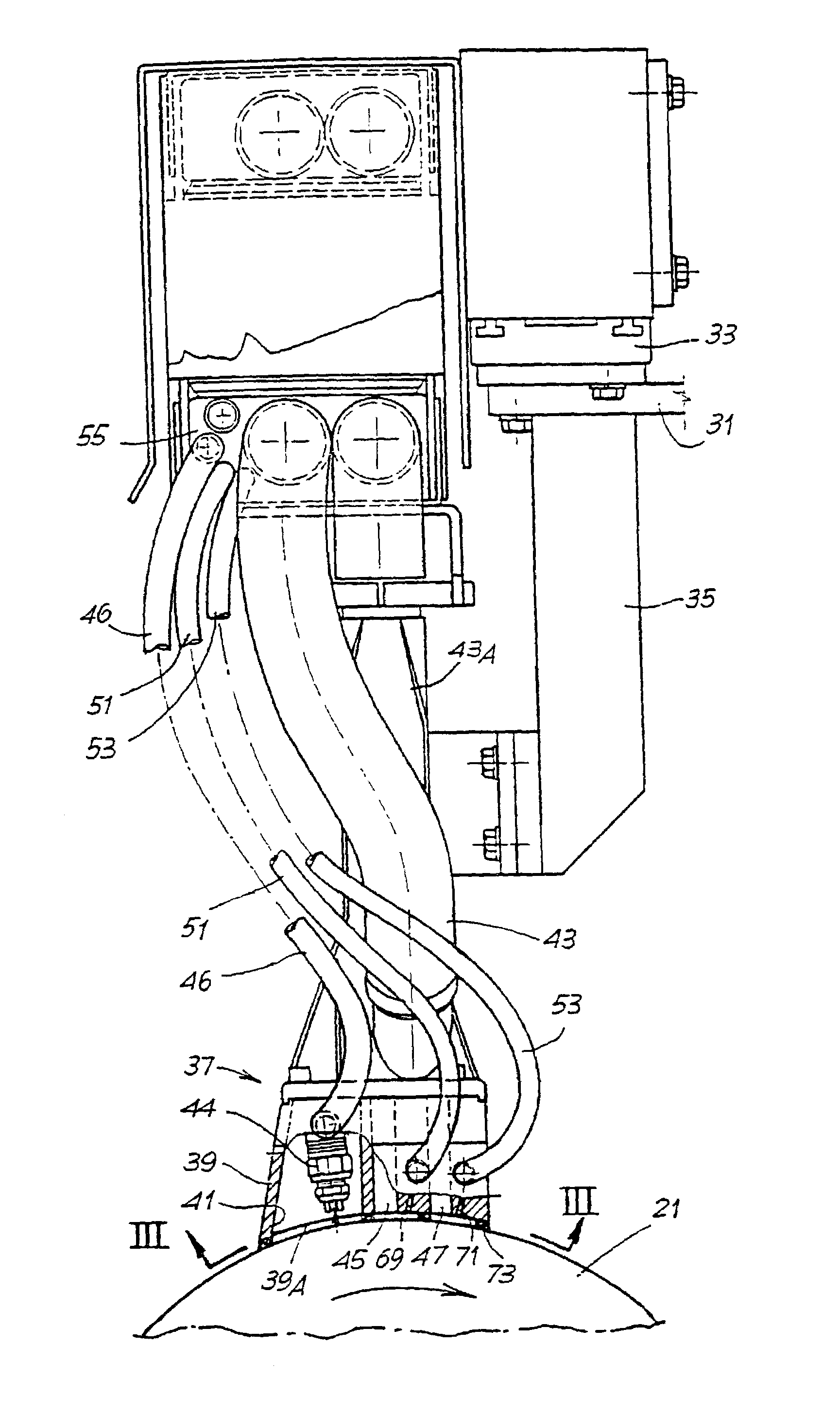

[0036]As an example of application of the invention, FIG. 1 shows diagrammatically, in lateral view, a flexographic press having four printing assemblies, for the four basic colors, to each of which a washing device according to the invention is fitted.

[0037]More particularly, the press comprises a main drum 3 about which is passed the substrate to be printed, represented by a web material N, for example a strip of paper, plastic or the like. The direction of advance of the web material N is designated fN. Said material is guided around rollers 5, 7, 9, 11 and 13.

[0038]Arranged around the central drum 3 are four printing assemblies designated 15A–15D. Each printing assembly comprises an inker 17, a screen cylinder 19 and a plate cylinder 21. The ink, delivered by the inker 17 to the screen cylinder 19, is transferred from the screen cylinder 19 to the plate cylinder 21. To the latter is applied an etched plate bearing the mirror image of the image, print or whatever else is to be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com