Vaporizer for MOCVD and method of vaporizing raw material solutions for MOCVD

a mocvd and raw material technology, applied in the direction of chemical vapor deposition coating, combustion air/fuel air treatment, refrigeration components, etc., can solve the problems of reducing storage capacitance, reducing yield, and unable to realize in 256 mbits or larger drams, so as to achieve stable feed of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

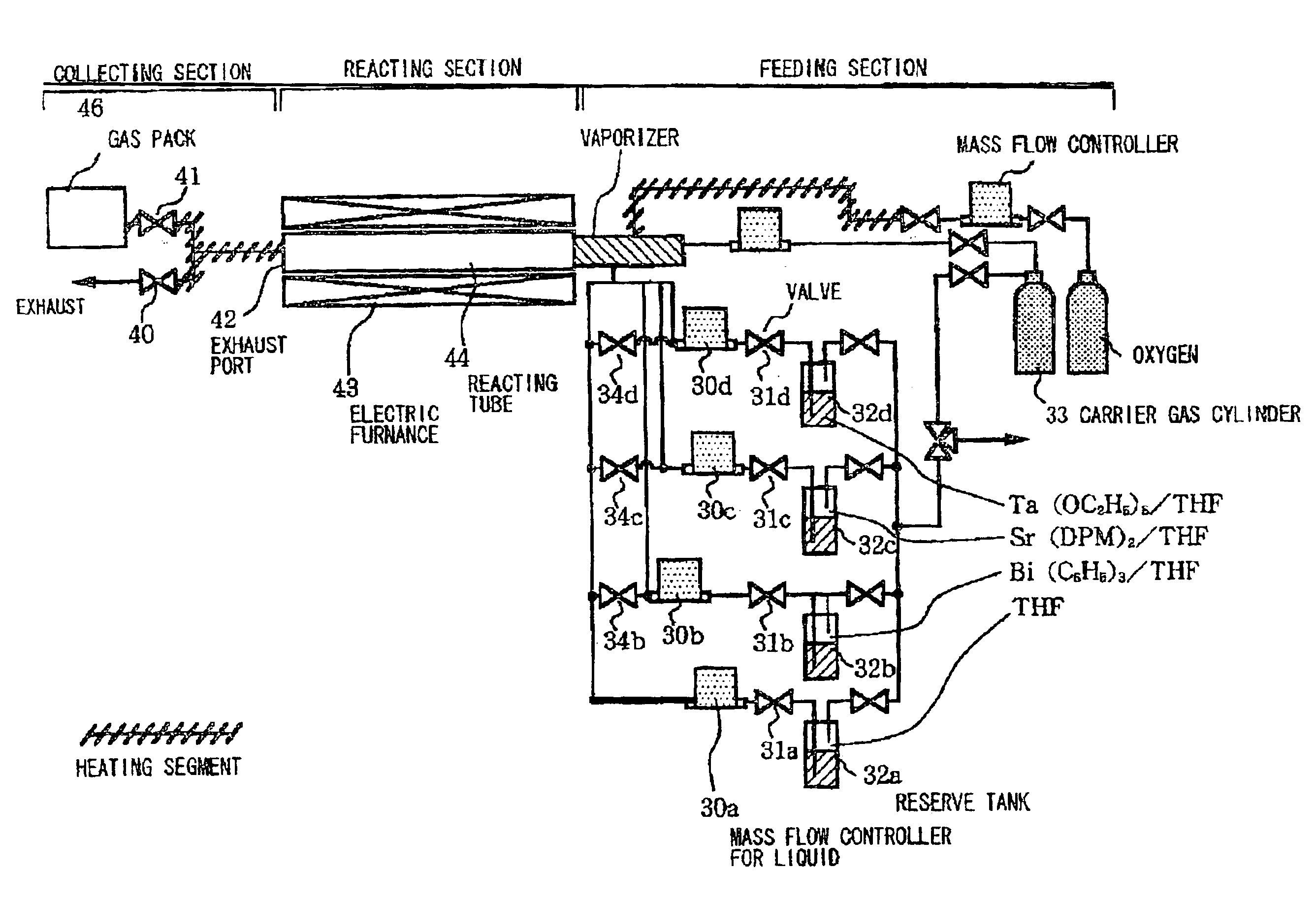

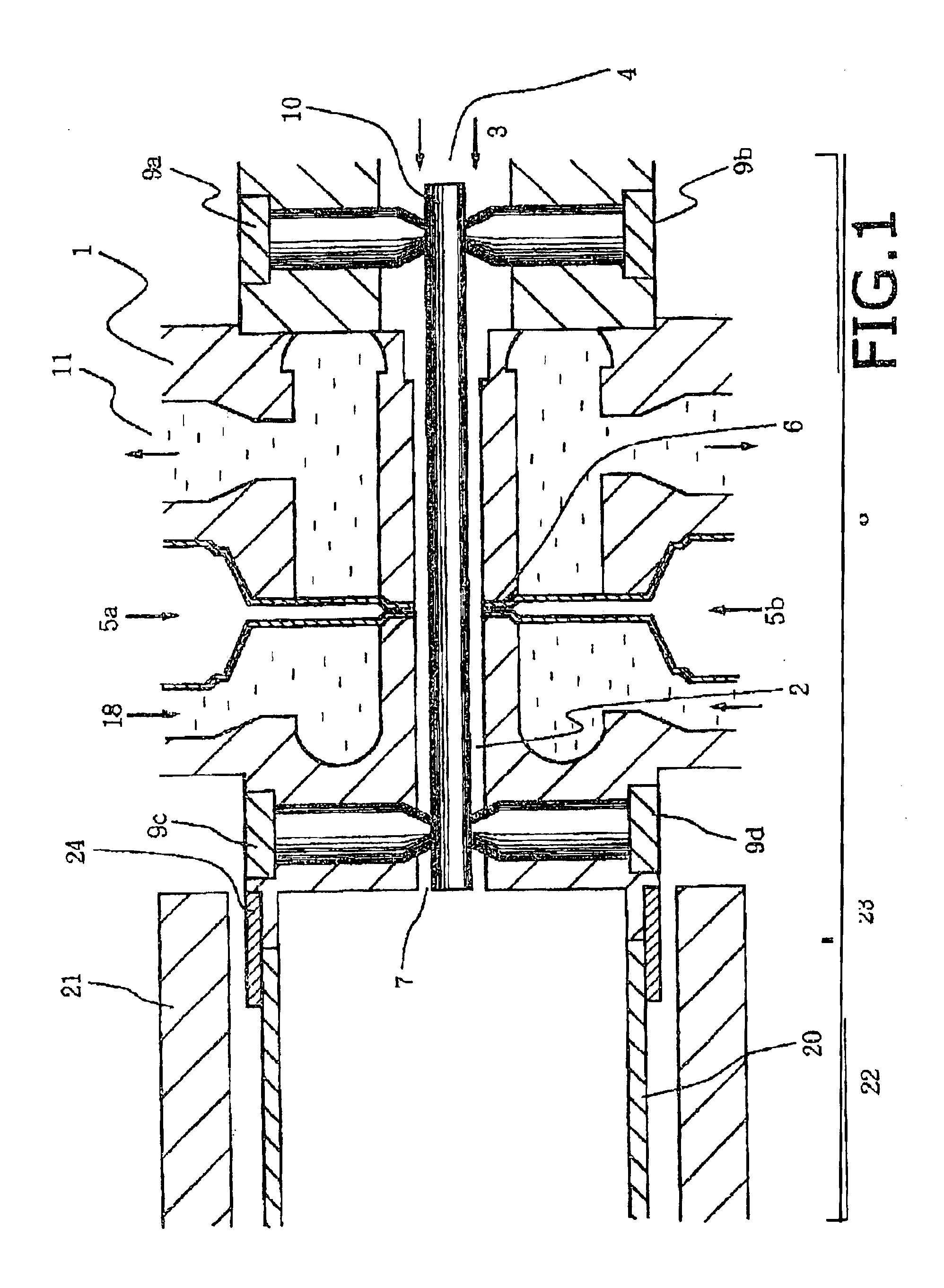

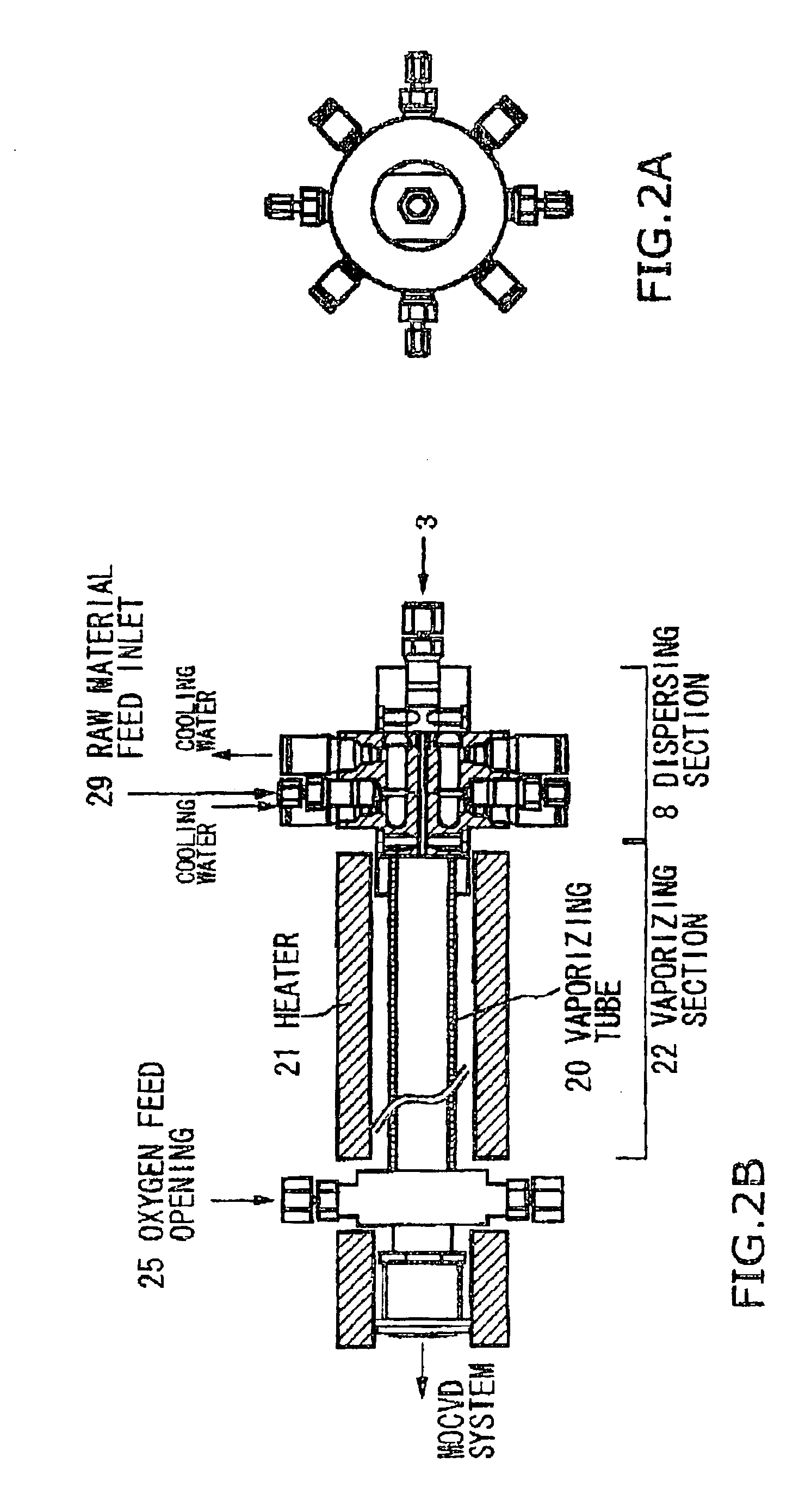

[0038]FIG. 1 illustrates a vaporizer for MOCVD in accordance with embodiment 1.

[0039]The vaporizer of this embodiment is constituted of a dispersing section 8 and a vaporizing section 22. The dispersing section 8 comprises a gas passage 2 formed in the interior of a dispersing section body 1 constituting the dispersing section 8, a gas introduction port 4 for introducing a carrier gas 3 under pressure into the gas passage 2, means (a raw material feed opening) 6 for feeding a raw material solution 5 to the carrier gas 3 passing through the gas passage 2, a gas outlet 7 for delivering the carrier gas 3 containing the dispersed raw material solution 5 to the vaporizing section 22, and means (cooling water) 18 for cooling the carrier gas 3 flowing through the gas passage 2. The vaporizing section 22 comprises a vaporizing tube 20 having one end connected to a reaction tube of the MOCVD system and having the other end connected to the gas outlet 7 of the dispersing section 8, and heatin...

embodiment 2

[0074]FIG. 5 illustrates a vaporizer for MOCVD in accordance with embodiment 2.

[0075]In the embodiment 1 the connecting section 23 was also subjected to heating by the heater 21, whereas in this embodiment the heater was provided only around the external periphery of the vaporizing section 22. Instead, cooling means 50 were provided around the external periphery of the connecting section 23 to cool the connecting section 23.

[0076]The others were the same as the embodiment 1.

[0077]In this embodiment, better coincidence was obtained than in the case of the embodiment 1 between detected products and products in the reaction formula examined on the basis of the reaction theory.

[0078]The result of measurement of the amount of adhesion of carbides on the external surface of the dispersing section body 1 toward the gas outlet 7 was about one third the amount of adhesion of carbides in the case of the embodiment 1.

embodiment 3

[0079]FIG. 6 illustrates a vaporizer for MOCVD in accordance with embodiment 3.

[0080]in this embodiment, the interior of the connecting section 23 has a tapered portion 51 with larger inner diameters from the dispersing section 8 toward the vaporizing section 22, Such a tapered portion 51 serves to eliminate any dead zones and contributes to the prevention of possible residence of the raw material.

[0081]The others were the same as the embodiment 1.

[0082]In this embodiment, better coincidence was obtained than in the case of the embodiment 2 between detected products and products in the reaction formula examined on the basis of the reaction theory.

[0083]Measurement of the amount of adhesion of carbides on the external surface of the dispersing section body 1 toward the gas outlet 7 resulted in substantially no adhesion of carbides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow velocity | aaaaa | aaaaa |

| relative dielectric constants | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com