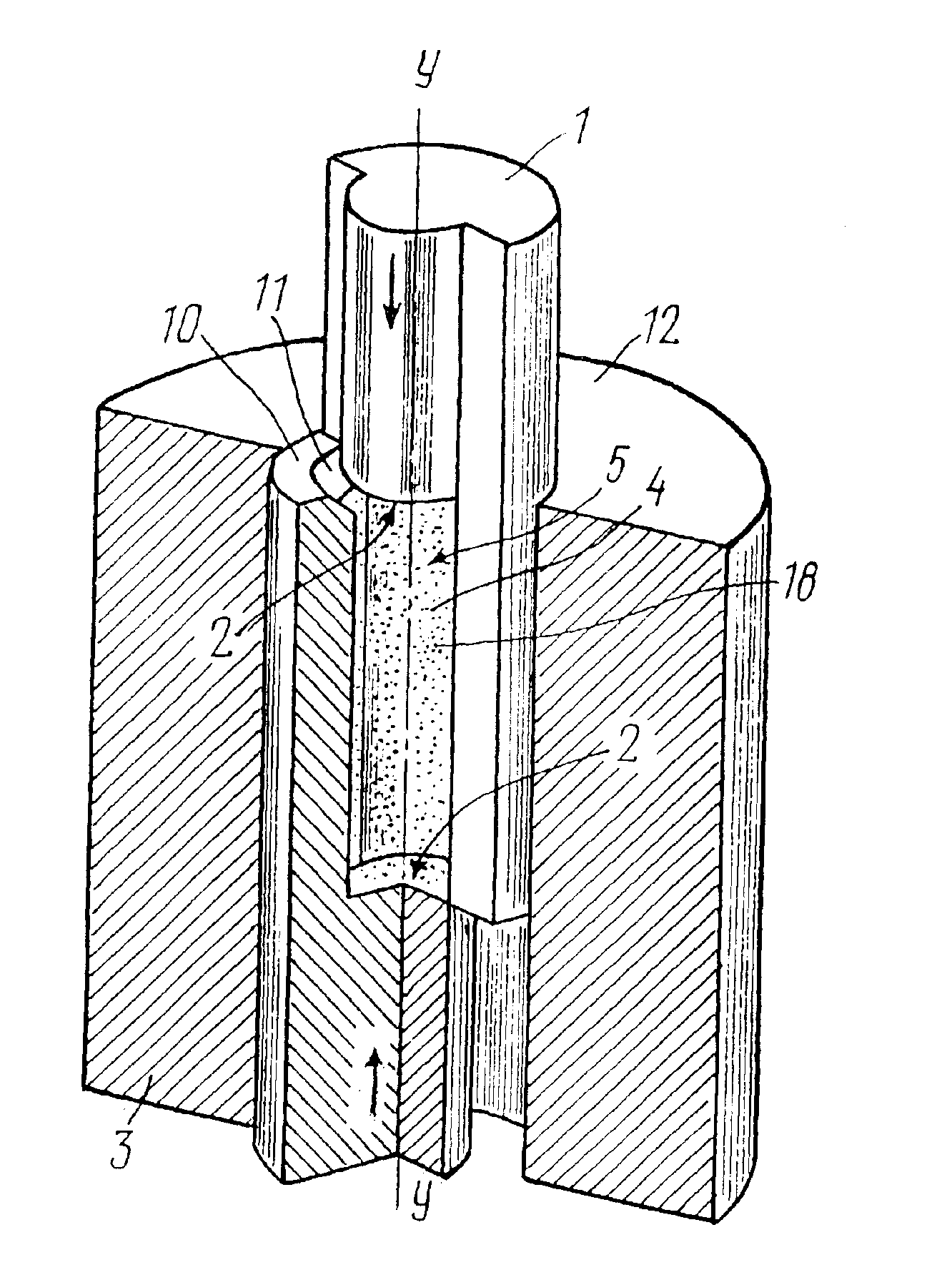

Method for compacting powder materials into articles and a mold for implementing the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

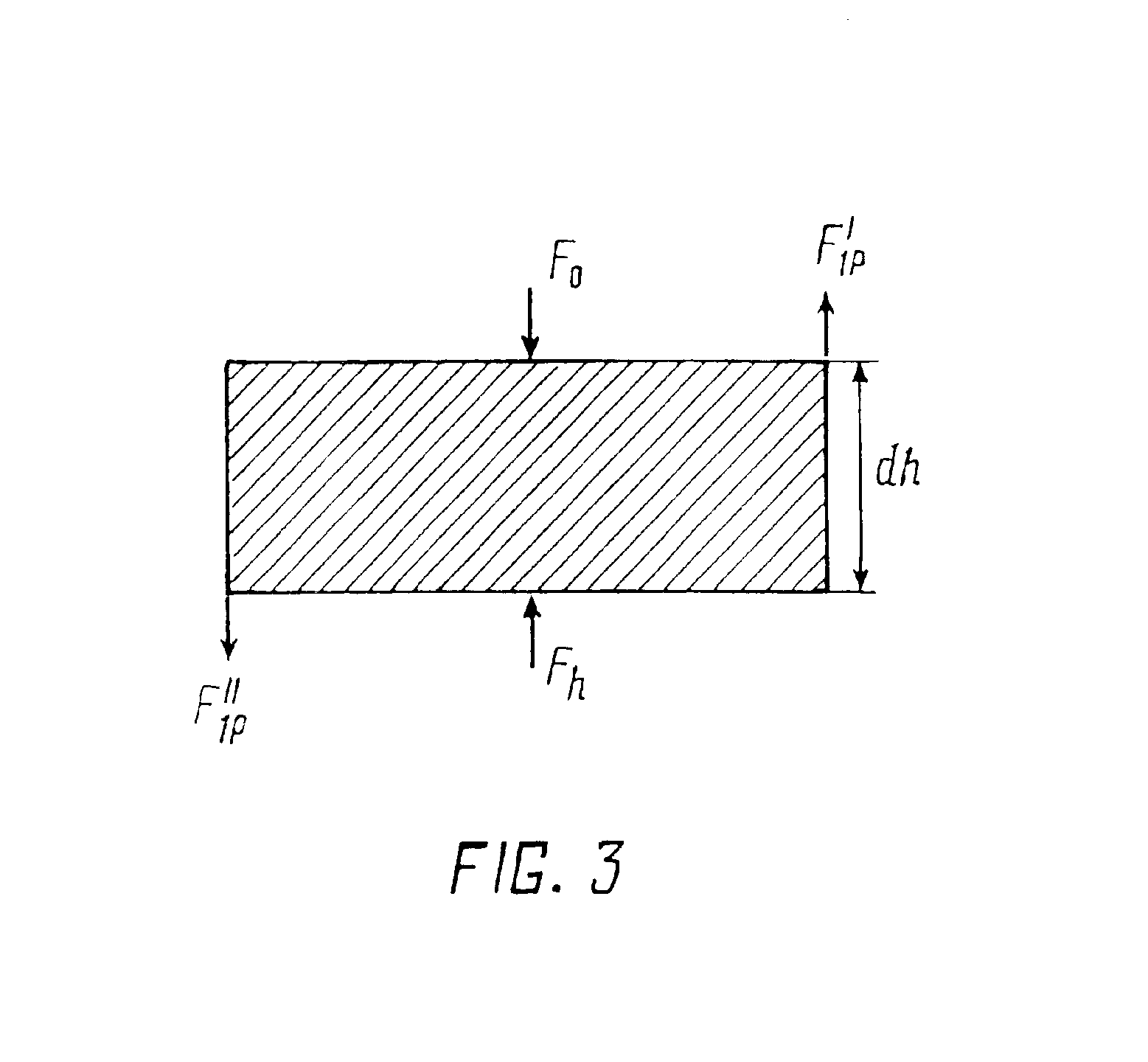

[0152]Using a method for compacting in accordance with the invention without lubricants, fluidizing agents and ultrasonic oscillation, articles of the seventh complexity group were fabricated of a raw plasmachemical finely dispersed powder of technical ceramic with the composition ZrO2-3 mole % Y2O3. None of the articles was defective.

[0153]The rated density differential along the height of the article fabricated by a prior art single-action static compacting was about 4%.

[0154]In the articles fabricated by the present method, the rated density differential was about 0.5% which correlates well with the differential value of 0.7-0.3% calculated from expression (13) depending on a floating or counter movement route of the insertion member. The nonzero density differential is explained by the fact that the condition of equality of parts of the passive shaping surface cannot be met in full measure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com