Shaping shoulder and a device for producing longitudinally shaped webs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

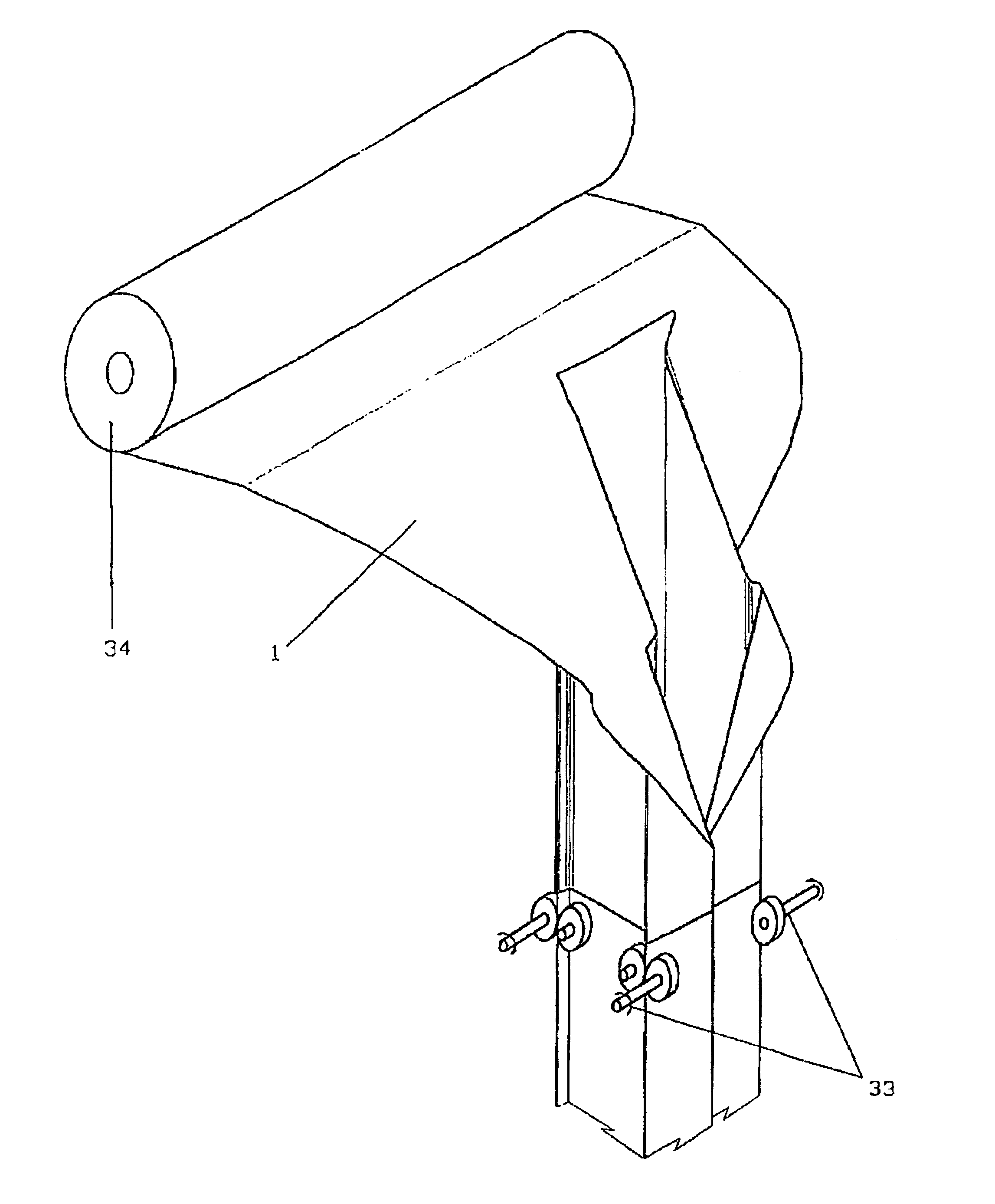

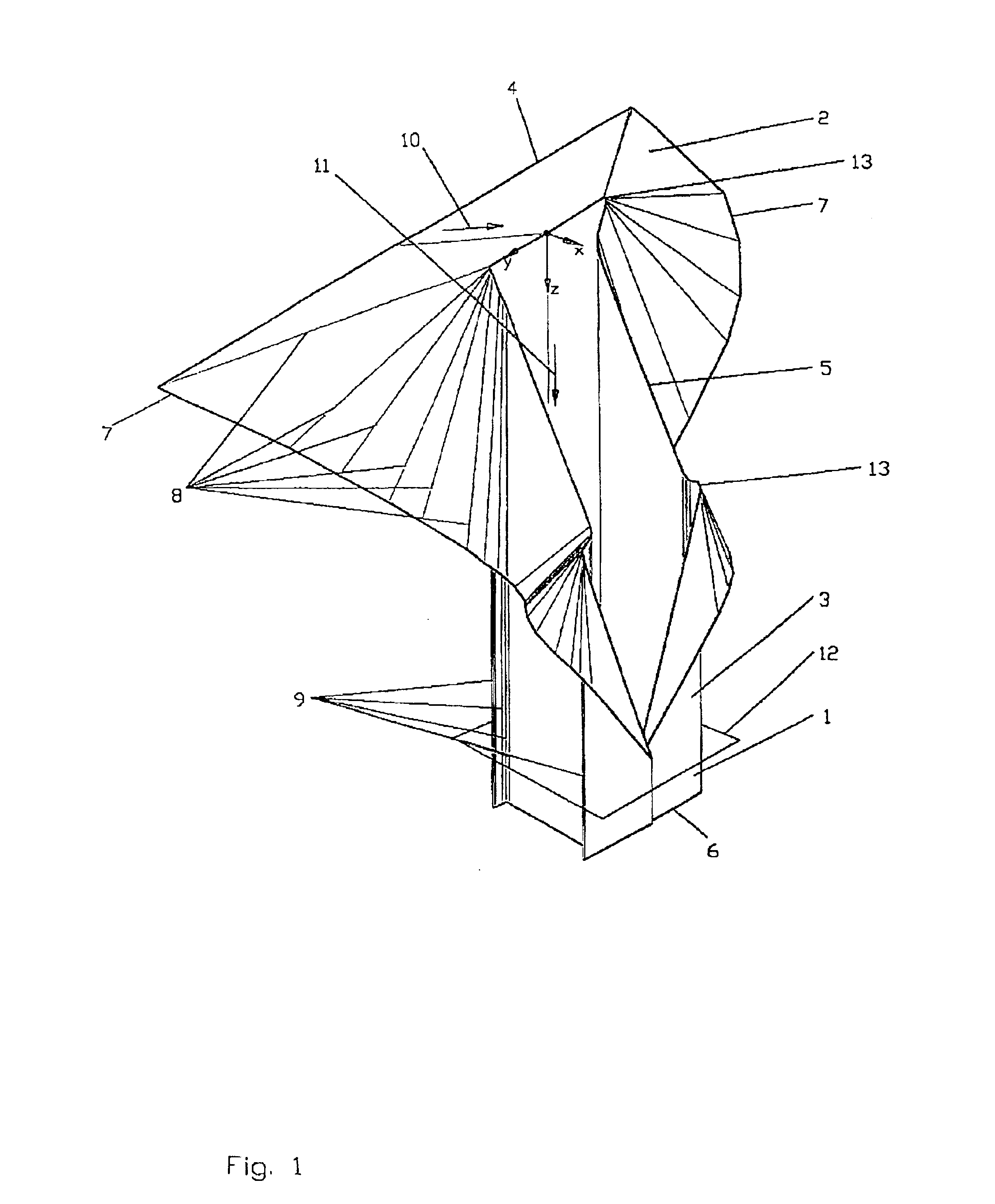

FIGS. 1 to 4 show a shaping shoulder for shaping a tube with four stabilizing folds in a perspective view (FIG. 1), in a plan view (FIG. 2), in a form developed in a plane (FIG. 3), as well as detail views of FIG. 2 and FIG. 3. The x-y-z coordinate system and the peripheral coordinate u facilitate orientation on the shaping shoulder.

The shaping shoulder (1) is comprised of a shoulder part (2) and a prism part (3). They are connected along the shaping edge (5). Viewed in the intake direction (10) of the web, the web moves from the web intake (4) on the shoulder part (2) via the shoulder part (2) to the shaping edge (5) and from there in the web transport direction (11) along the prism part (3) to the exit (6) of the tube. The web edge (7) extends along the outer boundary of the shoulder part (2).

The surface of the shoulder part (2) contacting the web is defined by straight lines, the shoulder edges (8), which extend from the shaping edge (5) to the web edge (7). The spacing between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com