6xxx aluminum alloys

a technology of aluminum alloys and alloys, applied in the field of new 6xxx aluminum alloys, can solve the problems of difficult to increase the strength of aluminum alloys without decreasing the corrosion resistance, and often elusive to achieve the effect of improving the combination of properties, improving the combination of strength, formability, bending and/or corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

position

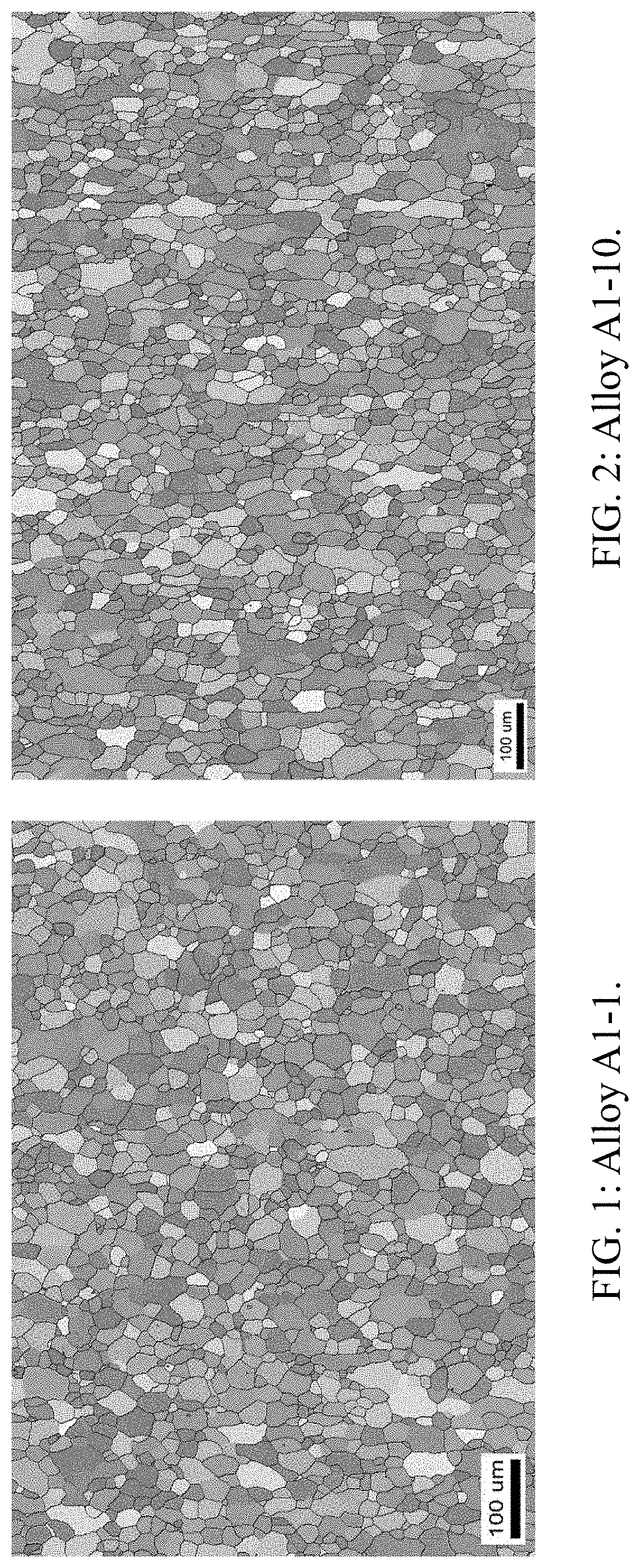

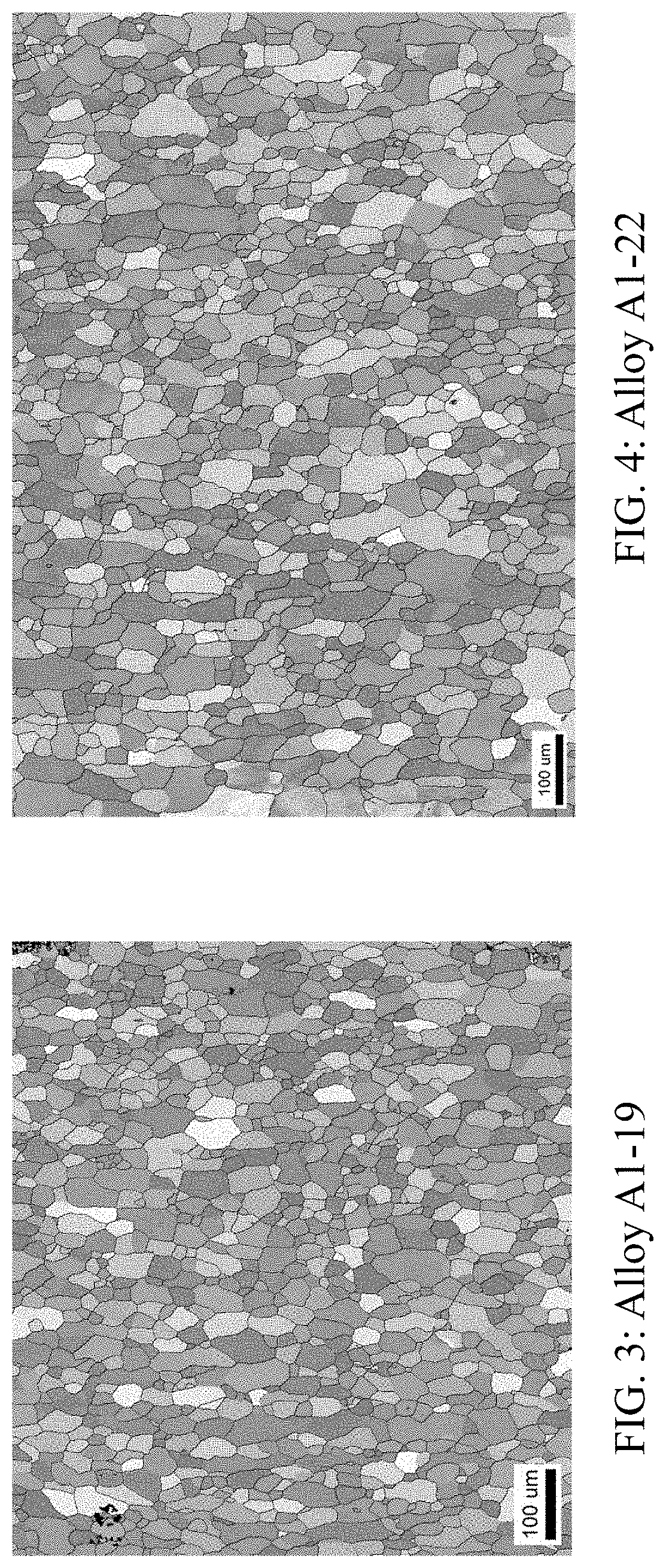

[0081]Aluminum alloys having the compositions shown in Table 1, below, were cast as ingots.

TABLE 1Compositions of Example 1 Alloys (wt. %)SampleSiFeCuMnMgCrTiZnBal.Alloy0.740.180.130.070.520.030.030.005A1 +A1Imp.(inv.)Alloy0.760.140.130.070.540.030.030.007A1 +A2Imp.(inv.)Alloy0.630.210.130.070.600.030.020.004A1 +B1Imp.(non-inv.)

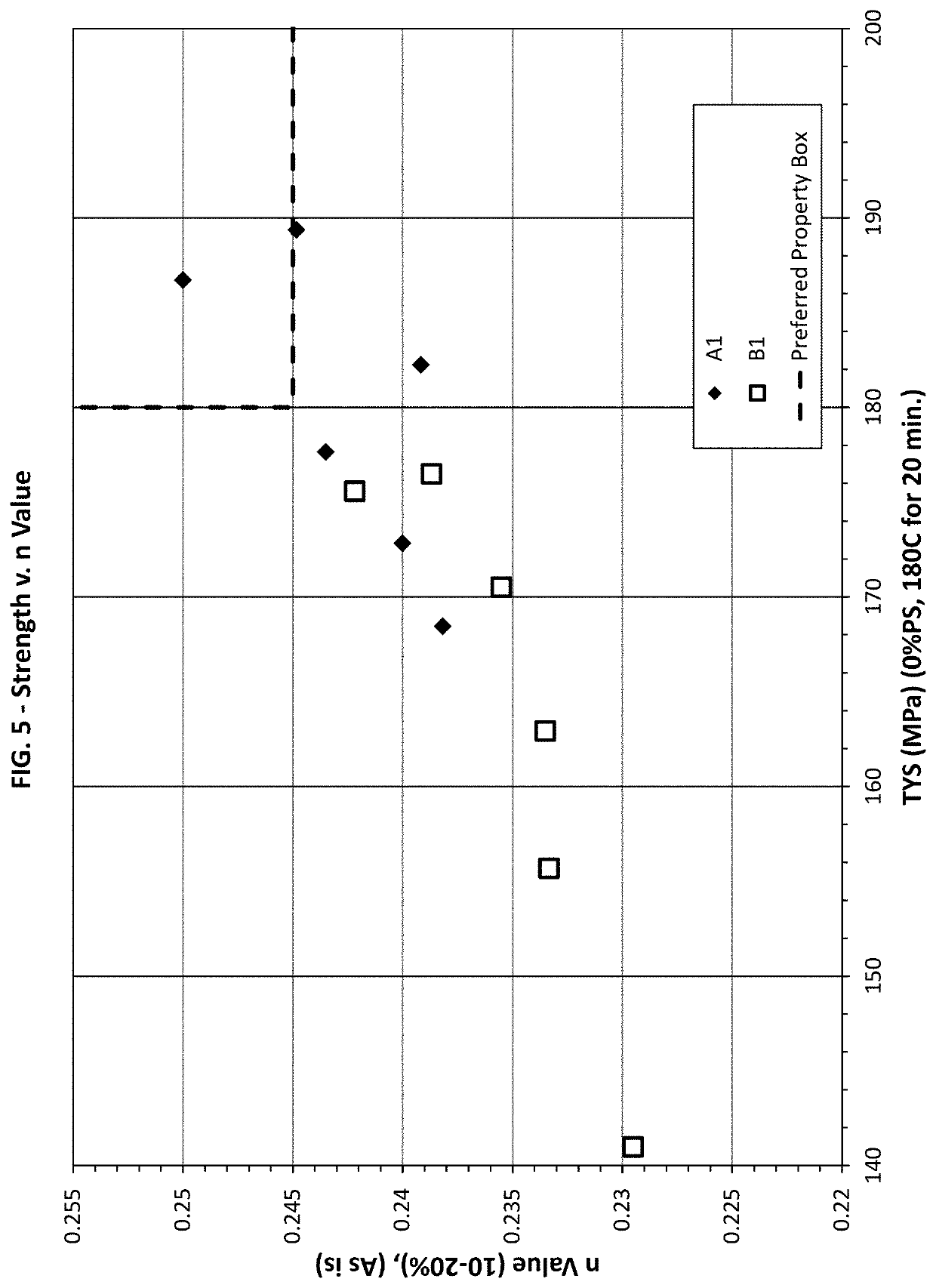

[0082]The ingots were then homogenized and then hot rolled to an intermediate gauge with an exit temperature of not greater than 290° C. The alloys were then cold rolled to a final gauge of 0.95 or 1.2 mm. The cold rolling amounts (reduction from the intermediate gauge to the final gauge) are provided in Table 2, below. The final gauge products were then solution heat treated by heating to various peak metal temperatures (shown in Table 2), after which the alloys were immediately air quenched. After quenching, some alloys were then stretched while others were not, as shown in Table 2. All alloys were then naturally aged for 30 days, after which some a...

example 2

rmance Testing

[0085]Select Example 1 alloys were tested for hemming performance by stretching them 15% in the L direction after which a flat hem test was performed. The stretching was completed on alloys that had been naturally aged for 30 days and without subsequent artificial aging, i.e., the alloys were in a T4 temper prior to the 15% stretching. Four hems were completed for each processing condition. The hem ratings were then evaluated per the below scale.

Hem Rating Scale1 or 2Mild (1) to moderate (2) orange peel withno cracking visible at 3x magnification3Crack(s) visible with 3x magnification4Cracks visible with naked eye

[0086]Table 4, below, shows the achieved hem ratings for A1 and A2 alloys.

TABLE 4Hem Ratings of Select Example 2 AlloysHemAlloyratingNumber(1-4)A1-12A1-22A1-32A1-102A1-112A1-122A1-192A1-202A1-212A1-222A1-232A1-242A2-12A2-22A2-32A2-102A2-112A2-122A2-192A2-202A2-212A2-223A2-233A2-243

[0087]A1 alloys have more iron than A2 alloys. Those in industry have associated...

example 3

Performance Testing

[0088]Select Example 1 were stretched 10% in the L direction and tested per the VDA 238-100 bend test specification. (https: / / www.vda.de / en / services / Publications / vda-238-100-plate-bending-test-for-metallic-materials.html) VDA stands for “Verband der Automobilindustrie”. The stretching was completed on alloys that has been naturally aged for 30 days and without subsequent artificial aging, i.e., the alloys were in a T4 temper prior to the 10% stretching. Table 5, below, shows the VDA bend test results for select Example 2 alloys.

TABLE 5VDA Bend Test Results of select Example 2 AlloysVDAAlloyBendNumberAngle (°)A1-10140A1-11142A1-12143A1-22129A1-23133A1-24137A2-10140A2-11141A2-12143A2-22127A2-23127A2-24129

[0089]At 65% cold work the A1 alloys demonstrated improved bending over the A2 alloys. It is believed that at least the difference in iron content contributed to this difference in properties. (A difference of 2° is a material difference at these levels of achieved ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| exit temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com